Nanocomposites exhibit superior mechanical, thermal, and barrier properties compared to microcomposites due to the high surface area and improved interfacial bonding of nanoparticles. The nanoscale filler dispersion enhances strength and toughness while maintaining lightweight characteristics, making them ideal for advanced engineering applications. Microcomposites, although easier to process, generally show lower performance in terms of durability and stiffness because of larger filler size and less effective stress transfer.

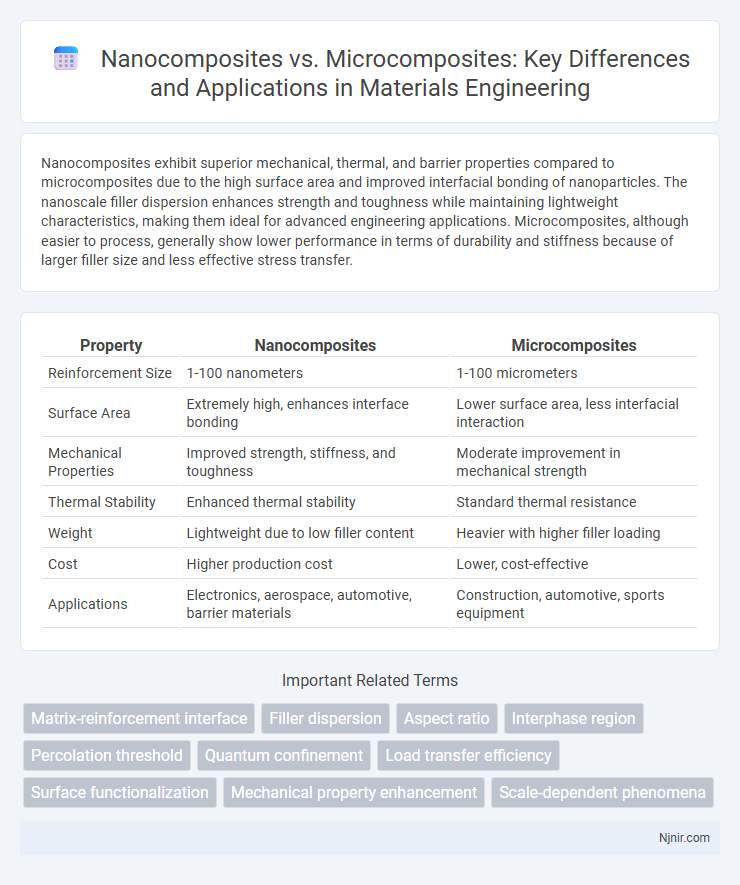

Table of Comparison

| Property | Nanocomposites | Microcomposites |

|---|---|---|

| Reinforcement Size | 1-100 nanometers | 1-100 micrometers |

| Surface Area | Extremely high, enhances interface bonding | Lower surface area, less interfacial interaction |

| Mechanical Properties | Improved strength, stiffness, and toughness | Moderate improvement in mechanical strength |

| Thermal Stability | Enhanced thermal stability | Standard thermal resistance |

| Weight | Lightweight due to low filler content | Heavier with higher filler loading |

| Cost | Higher production cost | Lower, cost-effective |

| Applications | Electronics, aerospace, automotive, barrier materials | Construction, automotive, sports equipment |

Introduction to Composite Materials

Composite materials combine two or more distinct phases to achieve superior properties compared to individual components. Nanocomposites incorporate nanoscale fillers, such as carbon nanotubes or graphene, enhancing mechanical strength, thermal stability, and electrical conductivity at minimal filler content. Microcomposites utilize microscale reinforcements like glass or carbon fibers, offering improved toughness and stiffness but often requiring higher filler loading for comparable performance gains.

Defining Nanocomposites and Microcomposites

Nanocomposites are materials composed of a matrix embedded with nanoscale particles, typically less than 100 nanometers in size, which significantly enhance mechanical, thermal, and barrier properties due to high surface area and quantum effects. Microcomposites, in contrast, incorporate larger filler particles, generally in the micrometer range, resulting in improved stiffness and strength but less pronounced enhancements in surface-related properties. The defining distinction lies in particle scale, with nanocomposites offering superior interfacial interaction and multifunctional performance compared to microcomposites.

Key Differences in Structure and Scale

Nanocomposites possess filler particles typically below 100 nanometers, significantly smaller than the micrometer-sized fillers in microcomposites, resulting in distinct interfacial interactions and improved mechanical, thermal, and barrier properties. The nanoscale fillers in nanocomposites create a larger surface area-to-volume ratio, enhancing dispersion and interaction with the polymer matrix, whereas microcomposites have less surface interaction due to larger particle size. These structural and scale differences directly influence the composites' performance, with nanocomposites often offering superior strength, toughness, and multifunctionality compared to microcomposites.

Manufacturing Processes and Techniques

Nanocomposites are typically manufactured using advanced techniques such as sol-gel processing, electrospinning, and layer-by-layer assembly, which enable precise dispersion and alignment of nanoparticles within the matrix. Microcomposites rely on conventional methods like melt blending, compression molding, and extrusion, where microscale fillers are mixed directly with polymer matrices. The nanoscale fillers in nanocomposites demand meticulous control during processing to prevent agglomeration, enhancing mechanical, thermal, and barrier properties compared to the coarser and less uniform distribution in microcomposites.

Mechanical Properties and Performance

Nanocomposites exhibit superior mechanical properties compared to microcomposites due to their enhanced interfacial bonding and uniform dispersion of nanoparticles within the matrix. The nanoscale fillers provide higher strength, stiffness, and toughness by effectively hindering crack propagation and improving load transfer efficiency. Microcomposites, while easier to process, often suffer from stress concentration points leading to lower mechanical performance and reduced durability in demanding applications.

Thermal and Electrical Conductivity Comparison

Nanocomposites exhibit significantly enhanced thermal and electrical conductivity compared to microcomposites due to their high surface area-to-volume ratio and uniform nanoparticle dispersion, which facilitates efficient charge and heat transfer pathways. The nanoscale fillers in nanocomposites create percolation networks at lower filler concentrations, resulting in superior conductive properties than microcomposites that rely on larger, less uniformly distributed particles. These characteristics make nanocomposites ideal for advanced applications requiring lightweight materials with optimized thermal management and electrical conductivity.

Applications in Industry and Technology

Nanocomposites exhibit superior mechanical strength, thermal stability, and electrical conductivity compared to microcomposites, making them ideal for advanced aerospace components, flexible electronics, and high-performance automotive parts. Their enhanced surface area and nano-sized fillers lead to improved catalytic activity and barrier properties, crucial for packaging, sensors, and energy storage devices. Microcomposites serve well in construction, automotive, and consumer goods industries where cost-effectiveness and moderate performance are prioritized over the nanoscale benefits.

Challenges and Limitations

Nanocomposites face challenges in achieving uniform nanoparticle dispersion and preventing agglomeration, which can compromise mechanical properties and functionality. Microcomposites exhibit limitations related to lower surface area-to-volume ratios, resulting in less effective reinforcement and reduced interfacial bonding strength. Both materials encounter processing difficulties, but nanocomposites demand stricter control over synthesis parameters to maintain desired nano-scale features.

Future Trends in Composite Development

Nanocomposites exhibit superior mechanical strength, thermal stability, and electrical conductivity compared to microcomposites, driving increased research and application in advanced aerospace and electronics. The future of composite development focuses on enhancing nanofiller dispersion and interface engineering to unlock multifunctional properties and sustainable manufacturing processes. Emerging trends emphasize hybrid nanocomposites, bio-based nanomaterials, and smart composites with self-healing and sensing capabilities, transforming material performance and lifecycle management.

Conclusion: Choosing the Right Composite

Nanocomposites offer superior mechanical, thermal, and barrier properties due to their nanoscale filler dispersion, making them ideal for applications requiring enhanced strength and durability with minimal weight increase. Microcomposites, while generally easier to process and often more cost-effective, provide adequate performance for less demanding structural uses but lack the multifunctionality seen in nanocomposites. Selecting the appropriate composite depends on application-specific requirements, balancing factors like mechanical performance, cost, and processing complexity.

Matrix-reinforcement interface

Nanocomposites exhibit significantly enhanced mechanical properties compared to microcomposites due to their increased matrix-reinforcement interfacial area, which promotes superior stress transfer and improved bonding at the nanoscale interface.

Filler dispersion

Nanocomposites exhibit superior filler dispersion with nanoparticles uniformly distributed at the molecular level, resulting in enhanced mechanical, thermal, and barrier properties compared to the coarser, less homogeneously dispersed fillers in microcomposites.

Aspect ratio

Nanocomposites feature significantly higher aspect ratios than microcomposites, resulting in enhanced mechanical, thermal, and barrier properties due to increased surface area and improved interfacial interactions.

Interphase region

Nanocomposites exhibit a significantly larger and more functional interphase region than microcomposites, enhancing mechanical, thermal, and barrier properties due to increased surface area and improved matrix-filler interactions.

Percolation threshold

Nanocomposites exhibit a significantly lower percolation threshold than microcomposites due to their higher surface area-to-volume ratio, enabling enhanced electrical and mechanical properties at lower filler concentrations.

Quantum confinement

Nanocomposites exhibit significant quantum confinement effects that enhance their electronic and optical properties compared to microcomposites, which lack these nanoscale quantum phenomena.

Load transfer efficiency

Nanocomposites exhibit significantly higher load transfer efficiency than microcomposites due to their larger interfacial area and improved stress distribution at the nanoscale.

Surface functionalization

Surface functionalization in nanocomposites enhances interfacial bonding and dispersion at the nanoscale, significantly improving mechanical, thermal, and barrier properties compared to microcomposites.

Mechanical property enhancement

Nanocomposites significantly enhance mechanical properties such as tensile strength, stiffness, and impact resistance compared to microcomposites due to their higher surface area-to-volume ratio and improved interfacial bonding between the matrix and nanofillers.

Scale-dependent phenomena

Nanocomposites exhibit enhanced mechanical, thermal, and electrical properties compared to microcomposites due to scale-dependent phenomena such as increased surface area-to-volume ratio and significant interfacial interactions at the nanoscale.

Nanocomposites vs Microcomposites Infographic

njnir.com

njnir.com