Corrosion resistance and oxidation resistance are critical properties in materials engineering that determine the longevity and performance of metals in various environments. Corrosion resistance refers to a material's ability to withstand degradation caused by chemical reactions with its environment, typically involving moisture and salts, whereas oxidation resistance specifically resists the formation of oxides when exposed to high temperatures and oxygen. Selecting materials with appropriate resistance properties ensures the structural integrity and reliability of components used in harsh industrial conditions.

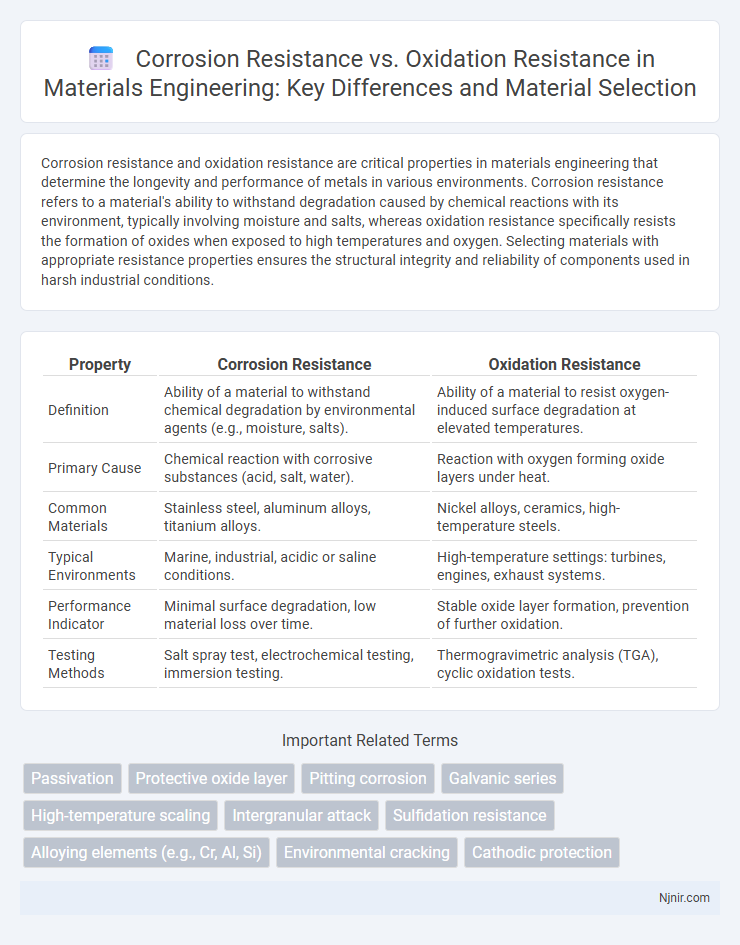

Table of Comparison

| Property | Corrosion Resistance | Oxidation Resistance |

|---|---|---|

| Definition | Ability of a material to withstand chemical degradation by environmental agents (e.g., moisture, salts). | Ability of a material to resist oxygen-induced surface degradation at elevated temperatures. |

| Primary Cause | Chemical reaction with corrosive substances (acid, salt, water). | Reaction with oxygen forming oxide layers under heat. |

| Common Materials | Stainless steel, aluminum alloys, titanium alloys. | Nickel alloys, ceramics, high-temperature steels. |

| Typical Environments | Marine, industrial, acidic or saline conditions. | High-temperature settings: turbines, engines, exhaust systems. |

| Performance Indicator | Minimal surface degradation, low material loss over time. | Stable oxide layer formation, prevention of further oxidation. |

| Testing Methods | Salt spray test, electrochemical testing, immersion testing. | Thermogravimetric analysis (TGA), cyclic oxidation tests. |

Introduction to Corrosion and Oxidation in Materials Engineering

Corrosion resistance measures a material's ability to withstand chemical degradation from environmental interactions, primarily involving electrochemical reactions that deteriorate metals. Oxidation resistance specifically refers to a material's capacity to resist oxygen-induced chemical change, often forming a protective oxide layer that slows further damage. In materials engineering, understanding both corrosion and oxidation mechanisms is crucial for selecting alloys and coatings that ensure longevity and structural integrity in harsh environments.

Fundamental Differences: Corrosion Resistance vs Oxidation Resistance

Corrosion resistance refers to a material's ability to withstand chemical or electrochemical reactions with environmental elements, such as moisture, acids, and salts, that lead to surface degradation and material loss. Oxidation resistance specifically describes the capacity of a material, often metals, to resist reacting with oxygen at elevated temperatures, preventing the formation of oxides that impair structural integrity. Fundamentally, corrosion resistance involves broader environmental interactions including water and chemicals, while oxidation resistance predominantly focuses on high-temperature oxygen exposure and the prevention of oxide layer formation.

Underlying Mechanisms of Corrosion and Oxidation

Corrosion resistance primarily depends on the material's ability to form a stable, protective oxide layer that prevents further metal degradation by electrochemical reactions with environmental elements. Oxidation resistance involves the material's capacity to withstand high-temperature exposure without forming volatile oxides or scaling, relying on slow diffusion rates of oxygen and metal ions within the oxide scale. Both processes hinge on the thermodynamic stability and adherence of oxide films, yet corrosion often involves aqueous environments and redox reactions, whereas oxidation typically occurs in dry, high-temperature atmospheres.

Material Selection Criteria for Harsh Environments

Corrosion resistance and oxidation resistance are critical factors in material selection for harsh environments, as corrosion involves chemical or electrochemical degradation by moisture or chemicals, while oxidation specifically refers to the reaction with oxygen at elevated temperatures. Materials such as stainless steel, titanium alloys, and high-performance ceramics offer superior corrosion resistance through passive oxide layers, while oxidation resistance is enhanced by alloys containing elements like aluminum or chromium that form stable, protective oxide scales. Selecting materials with combined corrosion and oxidation resistance ensures durability and longevity in aggressive industrial applications, including chemical processing, marine, and high-temperature environments.

Influence of Alloy Composition on Protective Properties

Alloy composition plays a critical role in determining both corrosion resistance and oxidation resistance by influencing the formation and stability of protective oxide layers. Elements such as chromium and aluminum enhance corrosion resistance by promoting the development of dense, adherent oxide films that act as barriers against aggressive environments. Meanwhile, the addition of silicon and nickel improves oxidation resistance by forming stable oxides at high temperatures, ensuring prolonged material integrity in oxidative atmospheres.

Surface Treatments and Coatings for Enhanced Resistance

Surface treatments and coatings significantly improve corrosion resistance by forming physical barriers that prevent moisture and chemicals from reaching the metal substrate, using methods like anodizing, galvanizing, and applying polymer or ceramic coatings. Oxidation resistance is enhanced through high-temperature coatings such as thermal barrier coatings and aluminide treatments that slow down oxide layer formation on metals exposed to elevated temperatures. Advanced techniques like plasma spraying and chemical vapor deposition enable precise application of these protective layers, optimizing durability in harsh chemical and high-temperature environments.

Testing Methods for Evaluating Corrosion and Oxidation Performance

Testing methods for evaluating corrosion resistance include salt spray tests, electrochemical impedance spectroscopy (EIS), and potentiodynamic polarization, which simulate corrosive environments and measure material degradation rates. Oxidation resistance is commonly assessed through thermogravimetric analysis (TGA) and high-temperature oxidation tests that monitor weight change and scale formation under controlled oxidative atmospheres. Combining these techniques provides comprehensive data on material durability in corrosive and oxidative conditions, crucial for applications in harsh industrial environments.

Industry Applications: Case Studies and Comparisons

Corrosion resistance is crucial in chemical processing plants where exposure to harsh acids and salts demands materials like stainless steel and Hastelloy, ensuring longevity and safety. Oxidation resistance plays a vital role in aerospace components subjected to high temperatures, where superalloys such as Inconel prevent degradation and maintain structural integrity. Case studies in marine and automotive industries reveal that selecting materials with tailored corrosion or oxidation resistance significantly reduces maintenance costs and enhances operational efficiency.

Recent Advances in Protective Material Technologies

Recent advances in protective material technologies have significantly enhanced corrosion resistance through the development of nano-structured coatings and self-healing polymers that inhibit electrochemical degradation in harsh environments. Innovations in oxidation resistance focus on high-entropy alloys and ceramic coatings capable of maintaining structural integrity and forming stable oxide layers at elevated temperatures. These materials extend the lifespan and reliability of components in aerospace, automotive, and energy sectors by combining tailored microstructures with advanced surface engineering.

Future Trends in Corrosion and Oxidation Resistance Research

Emerging trends in corrosion and oxidation resistance research emphasize the development of advanced nanocomposite coatings that enhance barrier properties and self-healing capabilities at elevated temperatures. Innovative material design leverages machine learning algorithms to predict corrosion behavior, enabling the creation of alloys with optimized microstructures for extended service life. Integration of sustainable, eco-friendly inhibitors alongside surface engineering techniques is driving the future landscape of durable, corrosion- and oxidation-resistant materials across aerospace and energy industries.

Passivation

Passivation enhances corrosion resistance by forming a stable oxide layer that prevents further oxidation and protects metals from environmental degradation.

Protective oxide layer

Corrosion resistance depends on the formation of a stable protective oxide layer that prevents material degradation, while oxidation resistance specifically refers to the ability of this layer to inhibit oxygen-induced damage at elevated temperatures.

Pitting corrosion

Pitting corrosion, a localized form of corrosion causing small cavities in metals, is more effectively mitigated by materials with high corrosion resistance through stable passive films, whereas oxidation resistance primarily protects against uniform surface degradation without specifically preventing pit initiation.

Galvanic series

Corrosion resistance and oxidation resistance in metals are influenced by their positions in the galvanic series, with metals higher in the series exhibiting greater corrosion resistance and those lower showing increased susceptibility to oxidation.

High-temperature scaling

High-temperature scaling demonstrates that corrosion resistance primarily prevents material degradation through chemical reactions with environmental elements, while oxidation resistance specifically inhibits oxygen-induced surface layer formation that compromises structural integrity.

Intergranular attack

Intergranular attack primarily compromises corrosion resistance by targeting grain boundaries, whereas oxidation resistance involves surface-scale formation protecting against environmental oxygen exposure.

Sulfidation resistance

Sulfidation resistance, a critical subset of corrosion resistance, specifically protects metals from chemical degradation caused by sulfur-containing gases at high temperatures, distinguishing it from general oxidation resistance which primarily defends against oxygen-induced surface deterioration.

Alloying elements (e.g., Cr, Al, Si)

Chromium enhances both corrosion and oxidation resistance by forming stable oxide layers, aluminum primarily improves oxidation resistance through protective alumina scale formation, and silicon boosts oxidation resistance while also contributing to moderate corrosion resistance in alloys.

Environmental cracking

Corrosion resistance prevents environmental cracking by inhibiting chemical degradation, while oxidation resistance specifically protects materials from high-temperature oxidative damage that can initiate or accelerate cracking.

Cathodic protection

Cathodic protection enhances corrosion resistance by preventing metal oxidation through controlled electrochemical reactions.

Corrosion resistance vs Oxidation resistance Infographic

njnir.com

njnir.com