Ultra-high Performance Concrete (UHPC) exhibits superior mechanical properties, including compressive strengths exceeding 150 MPa and exceptional durability compared to High-strength Concrete (HSC), which typically ranges from 50 to 100 MPa. The dense microstructure of UHPC results from optimized particle packing and the use of fine supplementary cementitious materials, enhancing its resistance to environmental degradation and extending service life. Differences in fiber reinforcement and curing methods also contribute to the remarkable tensile strength and toughness of UHPC, making it ideal for advanced structural applications where traditional HSC may fall short.

Table of Comparison

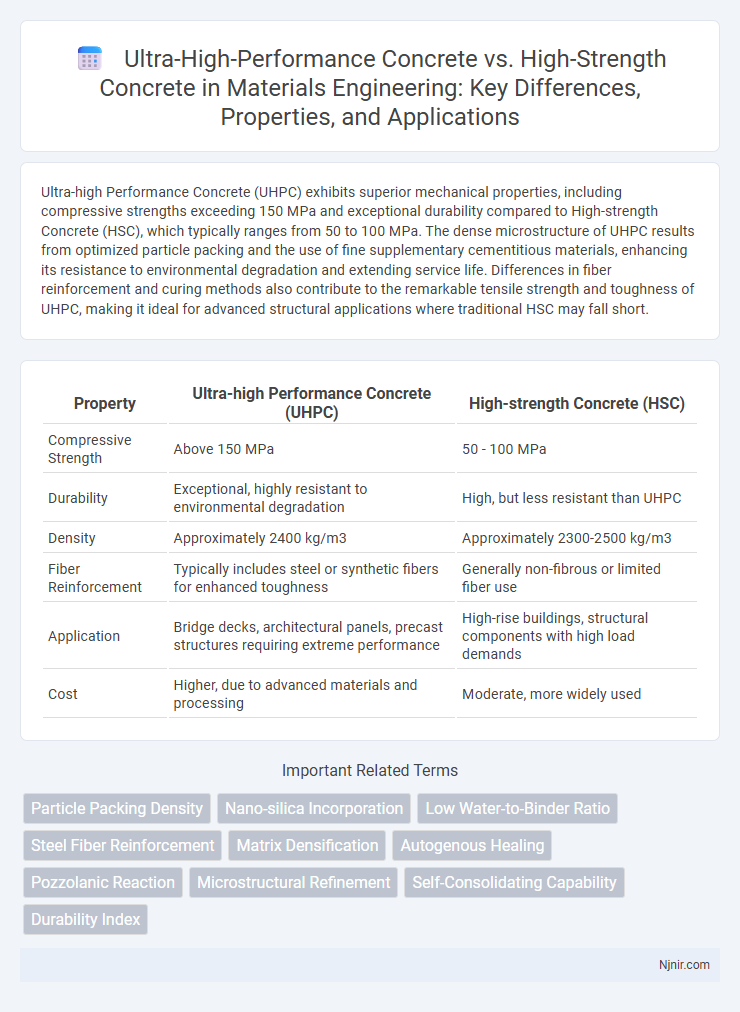

| Property | Ultra-high Performance Concrete (UHPC) | High-strength Concrete (HSC) |

|---|---|---|

| Compressive Strength | Above 150 MPa | 50 - 100 MPa |

| Durability | Exceptional, highly resistant to environmental degradation | High, but less resistant than UHPC |

| Density | Approximately 2400 kg/m3 | Approximately 2300-2500 kg/m3 |

| Fiber Reinforcement | Typically includes steel or synthetic fibers for enhanced toughness | Generally non-fibrous or limited fiber use |

| Application | Bridge decks, architectural panels, precast structures requiring extreme performance | High-rise buildings, structural components with high load demands |

| Cost | Higher, due to advanced materials and processing | Moderate, more widely used |

Introduction to Advanced Concrete Materials

Ultra-high Performance Concrete (UHPC) exhibits superior mechanical properties and durability compared to High-strength Concrete (HSC), achieved through optimized mixture designs incorporating fine powders, fibers, and low water-to-cement ratios. UHPC typically attains compressive strengths exceeding 150 MPa, while HSC usually ranges between 70-100 MPa, offering enhanced resistance to environmental degradation and structural loads. The advancement of these concrete materials reflects ongoing innovations in microstructure refinement and composite technology, enabling transformative applications in infrastructure and construction.

Defining Ultra-high Performance Concrete (UHPC)

Ultra-high Performance Concrete (UHPC) is a cementitious composite characterized by compressive strengths exceeding 150 MPa, exceptional durability, and enhanced ductility compared to conventional concretes. UHPC incorporates fine powders, high-range water reducers, and often steel fibers, resulting in a dense microstructure with improved mechanical properties and resistance to environmental degradation. Unlike standard High-strength Concrete (HSC), which typically attains compressive strengths ranging from 50 to 100 MPa, UHPC delivers superior performance suitable for demanding structural applications such as bridges and high-rise buildings.

Characteristics of High-strength Concrete (HSC)

High-strength concrete (HSC) typically exhibits compressive strengths above 40 MPa, achieved through a lower water-cement ratio and the use of high-quality materials such as silica fume and superplasticizers. Its dense microstructure enhances durability, reducing permeability and resistance to chemical attacks, making it suitable for structural components in high-rise buildings and bridges. HSC generally has higher modulus of elasticity and improved tensile strength compared to normal concrete, but it offers less ductility than ultra-high performance concrete (UHPC).

Key Differences Between UHPC and HSC

Ultra-high Performance Concrete (UHPC) offers superior compressive strength typically exceeding 150 MPa, compared to High-strength Concrete (HSC) which generally ranges from 50 to 100 MPa, enabling UHPC to support more demanding structural loads. UHPC incorporates advanced materials like fine powders, fibers, and optimized particle packing to achieve enhanced durability, ductility, and reduced permeability, whereas HSC mainly focuses on higher cement content and lower water-cement ratios. The microstructural improvements in UHPC result in improved resistance to chemical attacks and fatigue, distinct from HSC's conventional performance limits in harsh environmental conditions.

Mechanical Properties Comparison

Ultra-high performance concrete (UHPC) exhibits superior mechanical properties compared to high-strength concrete (HSC), with compressive strengths often exceeding 150 MPa versus HSC's typical range of 70-100 MPa. UHPC demonstrates enhanced tensile strength and ductility due to its dense microstructure and fiber reinforcement, resulting in improved fracture toughness and reduced brittleness. The modulus of elasticity in UHPC is also higher, contributing to better deformation resistance under heavy loads and elevated durability in extreme environmental conditions.

Durability and Longevity Aspects

Ultra-high Performance Concrete (UHPC) exhibits superior durability and longevity compared to High-strength Concrete (HSC) due to its dense microstructure and enhanced resistance to chemical attacks, freeze-thaw cycles, and abrasion. The inclusion of steel fibers and advanced admixtures in UHPC significantly reduces permeability, minimizing corrosion of reinforcement and extending service life beyond 100 years in severe environments. High-strength Concrete, while offering high compressive strength typically between 50-100 MPa, tends to have higher porosity, which can limit its durability under aggressive exposure conditions.

Material Composition and Mix Design

Ultra-high Performance Concrete (UHPC) features a denser matrix with fine powders such as silica fume, quartz flour, and high-range water reducers, combined with steel fibers to enhance tensile strength and durability. High-strength Concrete (HSC) primarily relies on a lower water-to-cement ratio, high cement content, and chemical admixtures to achieve compressive strengths typically between 50 to 100 MPa without fiber reinforcement. The optimized particle packing and use of supplementary cementitious materials in UHPC result in superior mechanical properties and durability compared to the conventional mix design of HSC.

Applications in Modern Construction

Ultra-high Performance Concrete (UHPC) excels in bridge construction, seismic-resistant structures, and architectural elements due to its exceptional compressive strength exceeding 150 MPa and superior durability. High-strength Concrete (HSC), with compressive strengths ranging from 40 to 80 MPa, is widely used for high-rise buildings, commercial complexes, and infrastructure projects where enhanced load-bearing capacity and reduced cross-sections are essential. The choice between UHPC and HSC depends on the specific requirements of impact resistance, longevity, and cost-effectiveness in modern construction applications.

Challenges and Limitations

Ultra-high Performance Concrete (UHPC) poses challenges including high material costs, complex mix design, and specialized curing requirements that limit widespread adoption compared to high-strength concrete (HSC). UHPC's dense microstructure and low water-to-cement ratio necessitate precise quality control, while its brittleness under certain loading conditions requires enhanced reinforcement strategies. HSC, although more economical and easier to produce, has lower durability and toughness than UHPC, restricting its use in extreme environments.

Future Trends in High-performance Concrete Technology

Future trends in high-performance concrete technology emphasize the advancement of Ultra-high Performance Concrete (UHPC) with enhanced durability, superior compressive strength exceeding 150 MPa, and exceptional fiber reinforcement techniques. Innovations in nanomaterials and optimized mix designs aim to improve sustainability by reducing cement content and incorporating recycled aggregates for eco-friendly construction. Smart concrete sensors integrated within UHPC structures enable real-time monitoring and predictive maintenance, revolutionizing infrastructure longevity and resilience.

Particle Packing Density

Ultra-high performance concrete achieves superior mechanical properties and durability compared to high-strength concrete primarily due to its optimized particle packing density, which minimizes voids and enhances microstructure compactness.

Nano-silica Incorporation

Nano-silica incorporation in Ultra-high Performance Concrete significantly enhances compressive strength, durability, and microstructural density compared to High-strength Concrete, due to its superior pozzolanic activity and particle packing effects.

Low Water-to-Binder Ratio

Ultra-high Performance Concrete features a significantly lower water-to-binder ratio, typically below 0.20, compared to High-strength Concrete's ratio of around 0.30, resulting in superior durability, reduced porosity, and enhanced compressive strength exceeding 150 MPa.

Steel Fiber Reinforcement

Ultra-high Performance Concrete with steel fiber reinforcement exhibits significantly enhanced tensile strength and durability compared to conventional high-strength concrete reinforced with traditional steel bars.

Matrix Densification

Ultra-high Performance Concrete exhibits superior matrix densification compared to High-strength Concrete, resulting in enhanced durability, reduced permeability, and increased mechanical properties.

Autogenous Healing

Ultra-high Performance Concrete exhibits significantly enhanced autogenous healing properties compared to High-strength Concrete due to its ultra-dense microstructure and optimized binder composition.

Pozzolanic Reaction

Ultra-high Performance Concrete exhibits enhanced pozzolanic reaction due to its optimized blend of fine silica and cementitious materials, resulting in superior durability and strength compared to High-strength Concrete.

Microstructural Refinement

Ultra-high Performance Concrete exhibits superior microstructural refinement compared to High-strength Concrete, resulting in denser matrix, reduced porosity, and enhanced mechanical properties.

Self-Consolidating Capability

Ultra-high Performance Concrete exhibits superior self-consolidating capability compared to high-strength concrete due to its optimized particle packing, reduced water-to-cement ratio, and use of superplasticizers.

Durability Index

Ultra-high Performance Concrete exhibits a significantly higher Durability Index than High-strength Concrete, with enhanced resistance to permeability, freeze-thaw cycles, and chemical attacks, ensuring longer structural lifespan.

Ultra-high Performance Concrete vs High-strength Concrete Infographic

njnir.com

njnir.com