Nanocellulose offers exceptional tensile strength and biodegradability, making it an eco-friendly alternative to traditional materials like Kevlar. Kevlar provides superior impact resistance and thermal stability, ideal for ballistic and industrial applications. Combining nanocellulose with Kevlar can enhance composite materials by improving strength-to-weight ratios and sustainability without compromising durability.

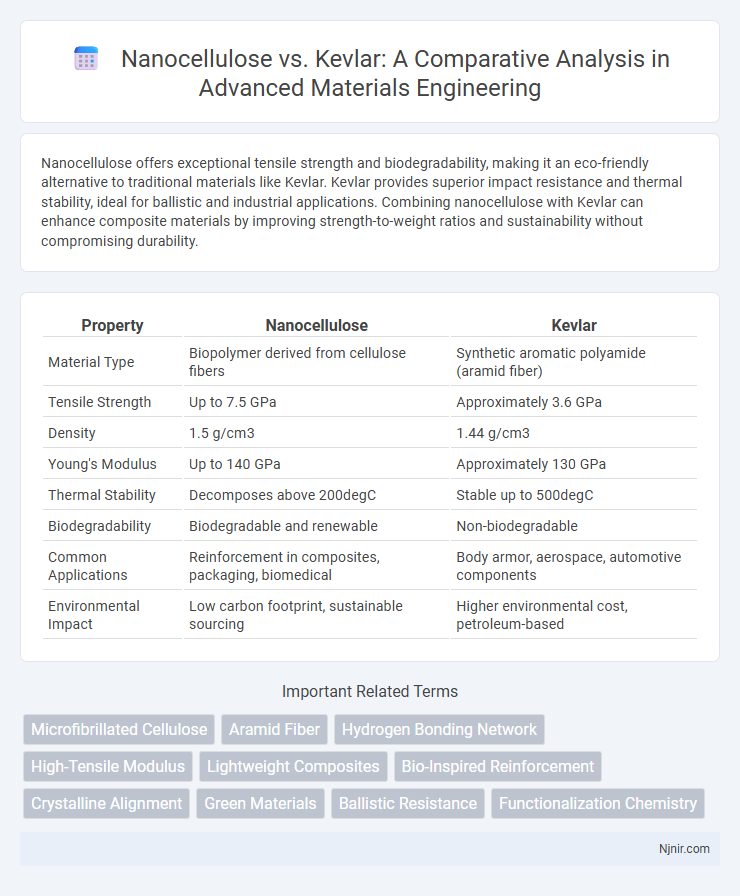

Table of Comparison

| Property | Nanocellulose | Kevlar |

|---|---|---|

| Material Type | Biopolymer derived from cellulose fibers | Synthetic aromatic polyamide (aramid fiber) |

| Tensile Strength | Up to 7.5 GPa | Approximately 3.6 GPa |

| Density | 1.5 g/cm3 | 1.44 g/cm3 |

| Young's Modulus | Up to 140 GPa | Approximately 130 GPa |

| Thermal Stability | Decomposes above 200degC | Stable up to 500degC |

| Biodegradability | Biodegradable and renewable | Non-biodegradable |

| Common Applications | Reinforcement in composites, packaging, biomedical | Body armor, aerospace, automotive components |

| Environmental Impact | Low carbon footprint, sustainable sourcing | Higher environmental cost, petroleum-based |

Introduction to Nanocellulose and Kevlar

Nanocellulose, derived from cellulose fibers found in plants, is a lightweight, biodegradable nanomaterial with exceptional mechanical strength and high surface area, making it an innovative alternative in composite materials. Kevlar, a para-aramid synthetic fiber developed by DuPont, is renowned for its high tensile strength, thermal stability, and resistance to impact, widely used in ballistic and protective applications. Both materials demonstrate superior durability but differ significantly in sustainability and chemical origin, with nanocellulose offering eco-friendly benefits compared to the petroleum-based Kevlar.

Structural Differences: Nanocellulose vs Kevlar

Nanocellulose consists of nanoscale cellulose fibrils derived from plant fibers, exhibiting exceptional tensile strength due to its crystalline structure and high aspect ratio. Kevlar, a synthetic aramid polymer, features rigid, rod-like molecular chains aligned through hydrogen bonding, creating a highly ordered, aromatic polyamide structure that imparts outstanding strength and thermal stability. The primary structural difference lies in nanocellulose's natural, carbohydrate-based crystalline fibrils versus Kevlar's synthetic, aromatic polyamide chains, influencing their respective mechanical and chemical properties.

Mechanical Properties Comparison

Nanocellulose exhibits exceptional tensile strength up to 7.5 GPa and a Young's modulus ranging from 100 to 150 GPa, offering high stiffness and lightweight characteristics compared to Kevlar's tensile strength of approximately 3.6 GPa and Young's modulus near 130 GPa. Nanocellulose's nano-scale fibril morphology enhances its specific strength and flexibility, enabling superior energy absorption and impact resistance in composite materials. Kevlar remains advantageous in thermal stability and chemical resistance, but nanocellulose outperforms in biodegradability and strength-to-weight ratio for sustainable engineering applications.

Thermal Stability and Performance

Nanocellulose exhibits excellent thermal stability with degradation temperatures typically around 250-300degC, making it suitable for moderate heat applications; however, Kevlar outperforms nanocellulose in thermal resistance, maintaining structural integrity up to approximately 450degC. Kevlar's aromatic polyamide chains provide superior thermal performance and flame retardance, essential for high-temperature environments such as aerospace and ballistic protection. While nanocellulose offers lightweight, renewable material benefits, Kevlar remains the preferred choice for applications demanding exceptional heat resistance and durability.

Sustainability and Environmental Impact

Nanocellulose offers significant sustainability advantages over Kevlar due to its renewable origin from plant biomass and its biodegradability, reducing environmental pollution. Kevlar, a synthetic aramid fiber derived from petrochemicals, involves energy-intensive production and challenges in disposal, contributing to long-term ecological footprints. The shift to nanocellulose supports a circular economy by minimizing reliance on fossil fuels and promoting lower carbon emissions throughout its lifecycle.

Processing Methods and Scalability

Nanocellulose is typically produced through mechanical fibrillation, chemical treatments, or enzymatic processes that allow for scalable, eco-friendly manufacturing from renewable biomass, while Kevlar synthesis involves complex polymerization and spinning techniques requiring high energy and stringent controls. Scaling nanocellulose production benefits from abundant cellulose sources and relatively low-cost processes, making it suitable for large-scale applications in composites and packaging. Kevlar's scalability is limited by costly precursor materials and specialized high-temperature polymerization, constraining its widespread use despite superior mechanical properties.

Applications in Advanced Composites

Nanocellulose offers lightweight, biodegradable reinforcement in advanced composites, enhancing mechanical strength and thermal stability for automotive and aerospace components. Kevlar is renowned for its exceptional tensile strength and impact resistance, making it ideal for ballistic protection, aerospace structural parts, and high-performance sporting goods. Integrating nanocellulose with Kevlar in hybrid composites can optimize durability, flexibility, and sustainability in next-generation materials.

Cost and Economic Viability

Nanocellulose offers a significantly lower production cost compared to Kevlar, primarily due to its abundant availability from renewable biomass sources like wood pulp and agricultural residues. Kevlar, derived from complex synthetic polymers, involves high energy consumption and expensive chemical processing, leading to elevated market prices. The economic viability of nanocellulose is enhanced by its sustainability and scalability, making it a cost-effective alternative for industries seeking lightweight, strong materials.

Safety and Biocompatibility

Nanocellulose exhibits superior safety and biocompatibility compared to Kevlar, as it is derived from renewable plant sources and is non-toxic to human tissues. Kevlar, a synthetic aramid fiber, poses potential health risks during manufacturing and can cause respiratory and skin irritation upon prolonged exposure. The biodegradable nature of nanocellulose also makes it an environmentally safer option, reducing adverse ecological impact compared to the non-degradable Kevlar fibers.

Future Trends and Research Directions

Nanocellulose exhibits significant potential as a sustainable alternative to Kevlar in advanced composite materials due to its exceptional mechanical strength, biodegradability, and abundant availability from renewable resources. Current research trends emphasize enhancing nanocellulose's barrier properties, optimizing its surface chemistry for better matrix compatibility, and scaling up production through cost-effective methods to compete with Kevlar's industrial applications. Future directions focus on integrating nanocellulose into multifunctional composites for aerospace, automotive, and protective equipment, leveraging its lightweight characteristics and environmental benefits to surpass Kevlar in performance and sustainability.

Microfibrillated Cellulose

Microfibrillated cellulose, a nanocellulose variant, offers superior tensile strength and lightweight properties compared to Kevlar, making it a sustainable alternative for advanced composite materials.

Aramid Fiber

Nanocellulose exhibits remarkable tensile strength and biodegradability, positioning it as a sustainable alternative to aramid fibers like Kevlar, which are renowned for exceptional durability, heat resistance, and widespread use in ballistic and protective applications.

Hydrogen Bonding Network

Nanocellulose exhibits a highly dense and robust hydrogen bonding network that enhances its mechanical strength and flexibility, contrasting Kevlar's less extensive hydrogen bonding which contributes to its rigid, aromatic polyamide structure.

High-Tensile Modulus

Nanocellulose demonstrates a high-tensile modulus often exceeding 100 GPa, rivaling Kevlar's tensile modulus of approximately 70-125 GPa, making it a competitive material for lightweight, high-strength applications.

Lightweight Composites

Nanocellulose offers superior tensile strength-to-weight ratio and enhanced biodegradability compared to Kevlar, making it an ideal material for developing lightweight composites in aerospace and automotive industries.

Bio-Inspired Reinforcement

Nanocellulose offers sustainable, lightweight bio-inspired reinforcement with high tensile strength and biodegradability, making it a promising alternative to synthetic Kevlar in advanced composite materials.

Crystalline Alignment

Nanocellulose exhibits superior crystalline alignment compared to Kevlar, enabling enhanced mechanical strength and flexibility at a molecular level.

Green Materials

Nanocellulose offers a sustainable and biodegradable alternative to Kevlar with comparable strength and lower environmental impact, making it a promising green material for advanced composites.

Ballistic Resistance

Nanocellulose exhibits remarkable ballistic resistance due to its high tensile strength and lightweight properties, making it a promising alternative to Kevlar in advanced protective armor applications.

Functionalization Chemistry

Nanocellulose offers versatile functionalization chemistry through hydroxyl group modifications enabling enhanced mechanical properties and biocompatibility, whereas Kevlar's aromatic polyamide structure limits functionalization primarily to surface treatments for improved adhesion and thermal resistance.

Nanocellulose vs Kevlar Infographic

njnir.com

njnir.com