Piezoelectric polymers offer flexibility and lightweight properties, making them ideal for wearable sensors and flexible electronic devices, whereas ferroelectric ceramics provide higher piezoelectric coefficients and thermal stability suited for high-performance actuators and transducers. The mechanical compliance of piezoelectric polymers enables better conformability to irregular surfaces, while ferroelectric ceramics demonstrate superior electrical responsiveness and durability under extreme conditions. Material selection depends on the application's demand for flexibility versus sensitivity and environment tolerance.

Table of Comparison

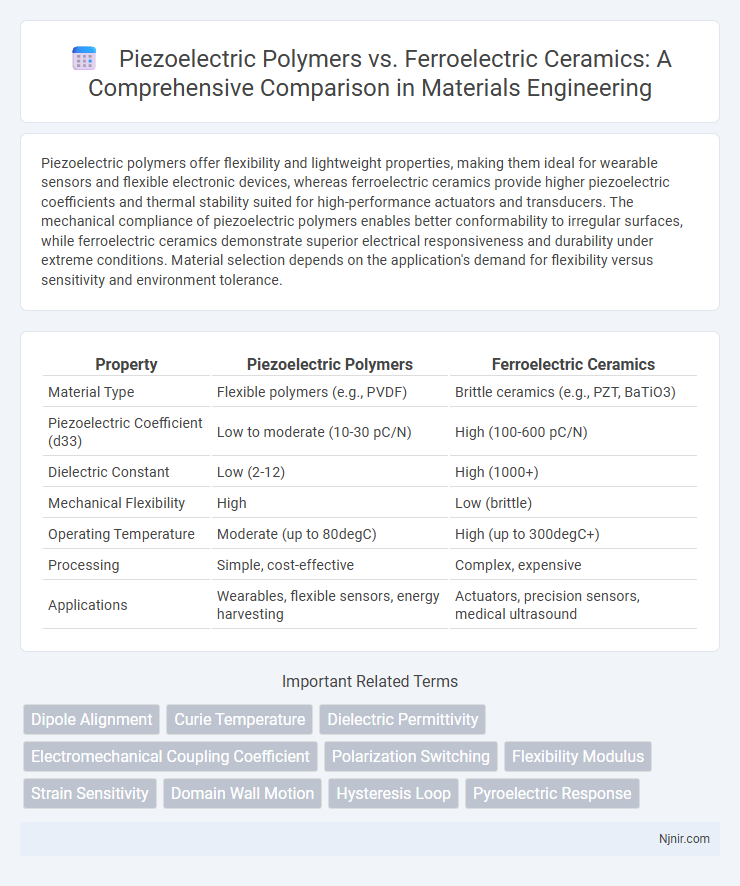

| Property | Piezoelectric Polymers | Ferroelectric Ceramics |

|---|---|---|

| Material Type | Flexible polymers (e.g., PVDF) | Brittle ceramics (e.g., PZT, BaTiO3) |

| Piezoelectric Coefficient (d33) | Low to moderate (10-30 pC/N) | High (100-600 pC/N) |

| Dielectric Constant | Low (2-12) | High (1000+) |

| Mechanical Flexibility | High | Low (brittle) |

| Operating Temperature | Moderate (up to 80degC) | High (up to 300degC+) |

| Processing | Simple, cost-effective | Complex, expensive |

| Applications | Wearables, flexible sensors, energy harvesting | Actuators, precision sensors, medical ultrasound |

Introduction to Piezoelectric Materials

Piezoelectric materials convert mechanical stress into electrical charge, enabling sensors, actuators, and energy harvesting applications. Piezoelectric polymers like PVDF offer flexibility, lightweight properties, and high mechanical strength, making them suitable for wearable devices and flexible electronics. Ferroelectric ceramics, such as PZT, provide higher piezoelectric coefficients and stability at elevated temperatures, ideal for precision sensors and medical ultrasound transducers.

Fundamental Principles: Piezoelectricity vs Ferroelectricity

Piezoelectric polymers generate an electric charge in response to mechanical stress due to the alignment of molecular dipoles without permanent polarization, enabling flexibility and lightweight applications. Ferroelectric ceramics exhibit spontaneous electric polarization that can be reversed by an external electric field, resulting in high piezoelectric coefficients and strong dielectric properties. The fundamental difference lies in piezoelectricity being a linear, stress-induced polarization in polymers, whereas ferroelectricity involves permanent dipole orientation and hysteresis effects in ceramics.

Structure and Composition: Polymers vs Ceramics

Piezoelectric polymers, such as polyvinylidene fluoride (PVDF), exhibit a flexible, chain-like molecular structure allowing them to generate electric charge under mechanical stress, while ferroelectric ceramics like lead zirconate titanate (PZT) possess a rigid, crystalline lattice with spontaneous polarization enabling strong piezoelectric responses. The polymer matrix consists of long organic molecules with dipolar groups aligned during poling, whereas ferroelectric ceramics have tightly bound ions in a perovskite crystal structure contributing to higher piezoelectric coefficients but brittleness. Differences in composition and structure result in polymers offering mechanical flexibility and lower density, contrasting with ceramics' superior piezoelectric performance and thermal stability.

Key Properties and Performance Metrics

Piezoelectric polymers, such as PVDF, exhibit flexibility, low density, and high tensile strain, making them ideal for wearable sensors and flexible electronics, whereas ferroelectric ceramics like PZT offer higher piezoelectric coefficients (d33 > 300 pC/N) and superior dielectric permittivity but are brittle and dense. The performance metrics emphasize polymers' low acoustic impedance and large strain capability versus ceramics' high electromechanical coupling factor and temperature stability. Understanding trade-offs in sensitivity, mechanical robustness, and frequency response is crucial for targeted applications in energy harvesting, actuators, and transducers.

Processing and Manufacturing Techniques

Piezoelectric polymers such as PVDF are processed using flexible techniques like spin coating, extrusion, and electrospinning, enabling thin, lightweight, and flexible sensor designs ideal for wearable electronics. Ferroelectric ceramics like PZT require high-temperature sintering and precise control of grain size during manufacturing, resulting in rigid, brittle structures with superior piezoelectric coefficients but limited mechanical flexibility. Polymer processing allows scalable production with lower energy input while ceramic fabrication demands stringent thermal profiles and often complex machining for device integration.

Applications in Sensing and Actuation

Piezoelectric polymers such as PVDF offer flexibility, lightweight properties, and high sensitivity, making them ideal for wearable sensors, flexible actuators, and biomedical devices. Ferroelectric ceramics like PZT exhibit higher piezoelectric coefficients and robust mechanical strength, suited for precision actuators, ultrasonic transducers, and high-frequency sensors. The choice between polymers and ceramics depends on the application's requirements for flexibility, sensitivity, durability, and operating frequency range.

Mechanical Flexibility and Durability Comparison

Piezoelectric polymers like PVDF offer superior mechanical flexibility compared to ferroelectric ceramics such as PZT, enabling bending and stretching without performance degradation. Ferroelectric ceramics exhibit higher piezoelectric coefficients but are brittle and prone to cracking under mechanical stress, limiting their durability in flexible applications. The durability of piezoelectric polymers makes them ideal for wearable devices and flexible sensors, whereas ferroelectric ceramics remain preferred in rigid, high-performance actuator systems.

Environmental Stability and Temperature Response

Piezoelectric polymers exhibit superior environmental stability due to their flexibility and resistance to moisture, making them ideal for applications with variable humidity and mechanical stress. Ferroelectric ceramics demonstrate higher temperature sensitivity and can operate at elevated temperatures up to 400degC, but their brittle nature limits durability under thermal cycling. Polymers provide consistent piezoelectric response over a wider temperature range, whereas ceramics offer stronger piezoelectric coefficients at the expense of environmental resilience.

Cost and Scalability Considerations

Piezoelectric polymers offer lower production costs and greater scalability due to their flexible manufacturing processes and compatibility with large-area applications, making them ideal for cost-sensitive or large-scale deployments. Ferroelectric ceramics, while providing higher piezoelectric coefficients and thermal stability, involve more expensive raw materials and complex fabrication techniques that limit cost efficiency and scalability. Choosing between these materials depends on balancing performance requirements with budget constraints and production volume needs.

Future Trends in Piezoelectric and Ferroelectric Materials

Future trends in piezoelectric and ferroelectric materials emphasize the integration of piezoelectric polymers and ferroelectric ceramics for enhanced flexibility and performance in wearable electronics. Advanced nanocomposite formulations combining PVDF-based polymers and lead-free ferroelectric ceramics such as barium titanate are projected to boost sensitivity and energy harvesting capabilities. Research also targets scalable manufacturing techniques and improved temperature stability to meet the demands of next-generation sensors, actuators, and flexible energy devices.

Dipole Alignment

Piezoelectric polymers exhibit flexible dipole alignment due to molecular chain orientation, while ferroelectric ceramics possess rigid, spontaneously aligned dipoles within their crystalline lattice, resulting in higher piezoelectric coefficients.

Curie Temperature

Ferroelectric ceramics exhibit higher Curie temperatures typically above 200degC, making them more suitable for high-temperature applications compared to piezoelectric polymers, which generally have Curie temperatures below 100degC.

Dielectric Permittivity

Ferroelectric ceramics exhibit significantly higher dielectric permittivity, typically ranging from 100 to over 1000, compared to piezoelectric polymers, which generally have lower permittivity values around 2 to 20.

Electromechanical Coupling Coefficient

Piezoelectric polymers exhibit lower electromechanical coupling coefficients, typically ranging from 0.1 to 0.3, compared to ferroelectric ceramics which achieve higher values between 0.5 and 0.7, making ceramics more efficient for energy conversion in electromechanical applications.

Polarization Switching

Piezoelectric polymers exhibit slower, less stable polarization switching compared to ferroelectric ceramics, which demonstrate rapid, robust, and high remnant polarization essential for efficient electromechanical applications.

Flexibility Modulus

Piezoelectric polymers exhibit significantly lower flexibility modulus compared to ferroelectric ceramics, enabling enhanced mechanical flexibility and suitability for wearable and flexible electronic applications.

Strain Sensitivity

Piezoelectric polymers exhibit higher strain sensitivity with greater flexibility and toughness compared to the typically brittle ferroelectric ceramics, making them ideal for applications requiring large mechanical deformation.

Domain Wall Motion

Domain wall motion in piezoelectric polymers is typically more flexible and exhibits lower coercive fields compared to the rigid, high-coercivity domain walls of ferroelectric ceramics, resulting in distinct electromechanical response behaviors.

Hysteresis Loop

Piezoelectric polymers exhibit a slim hysteresis loop with low energy loss and high flexibility, while ferroelectric ceramics display a pronounced hysteresis loop indicating strong polarization switching but increased energy dissipation.

Pyroelectric Response

Piezoelectric polymers exhibit lower pyroelectric response but offer flexibility and lightweight properties compared to ferroelectric ceramics, which provide higher pyroelectric coefficients and thermal stability ideal for precise temperature sensing applications.

Piezoelectric Polymers vs Ferroelectric Ceramics Infographic

njnir.com

njnir.com