Thermal barrier coatings (TBCs) are engineered to insulate components from extreme heat, enhancing the thermal stability and lifespan of materials in high-temperature environments such as gas turbines and aero engines. Wear-resistant coatings prioritize mechanical durability by reducing surface degradation caused by friction, abrasion, and impact, extending the service life of tools and machinery parts. Selecting between thermal barrier and wear-resistant coatings depends on the operational demands, whether thermal insulation or surface protection against wear is the primary requirement.

Table of Comparison

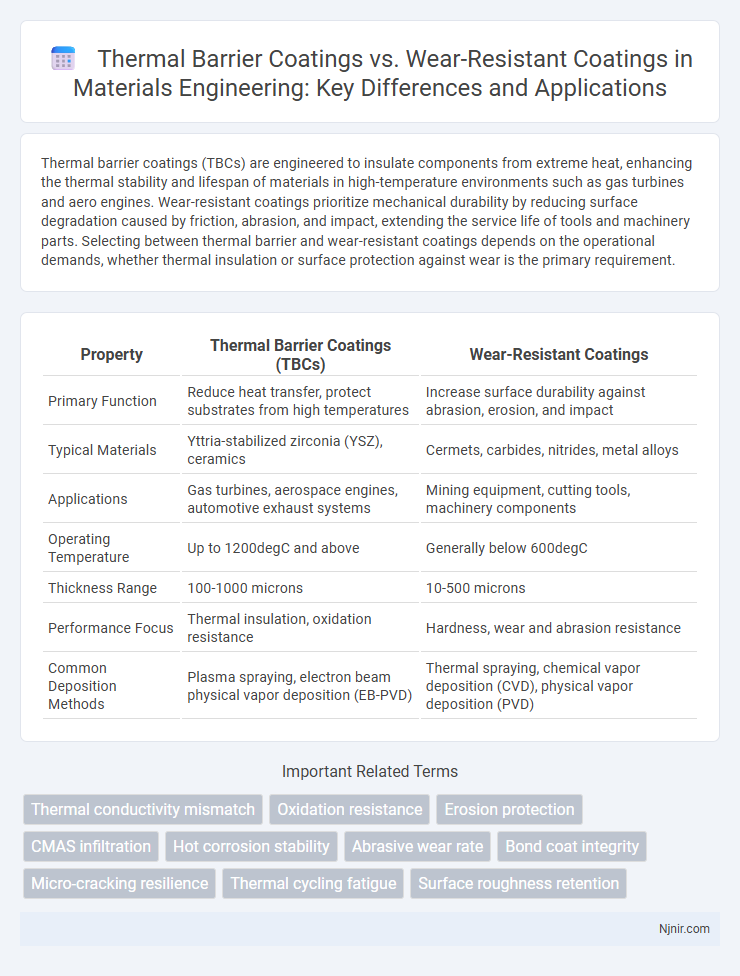

| Property | Thermal Barrier Coatings (TBCs) | Wear-Resistant Coatings |

|---|---|---|

| Primary Function | Reduce heat transfer, protect substrates from high temperatures | Increase surface durability against abrasion, erosion, and impact |

| Typical Materials | Yttria-stabilized zirconia (YSZ), ceramics | Cermets, carbides, nitrides, metal alloys |

| Applications | Gas turbines, aerospace engines, automotive exhaust systems | Mining equipment, cutting tools, machinery components |

| Operating Temperature | Up to 1200degC and above | Generally below 600degC |

| Thickness Range | 100-1000 microns | 10-500 microns |

| Performance Focus | Thermal insulation, oxidation resistance | Hardness, wear and abrasion resistance |

| Common Deposition Methods | Plasma spraying, electron beam physical vapor deposition (EB-PVD) | Thermal spraying, chemical vapor deposition (CVD), physical vapor deposition (PVD) |

Introduction to Advanced Surface Coatings in Materials Engineering

Thermal barrier coatings (TBCs) provide critical protection by insulating components from extreme heat, significantly enhancing the thermal performance and lifespan of turbine blades in aerospace and power generation industries. Wear-resistant coatings improve surface durability by reducing friction and resisting abrasion, which extends the service life of mechanical parts in manufacturing and automotive applications. Advanced surface coatings in materials engineering leverage tailored compositions and microstructures to optimize performance for specific operational environments, integrating both thermal and mechanical protection strategies.

Fundamentals of Thermal Barrier Coatings (TBCs)

Thermal barrier coatings (TBCs) are advanced ceramic layers primarily composed of yttria-stabilized zirconia (YSZ) designed to insulate metallic components from extreme heat, improving turbine efficiency and lifespan by reducing thermal conductivity and thermal strain. Wear-resistant coatings, in contrast, focus on mechanical durability and surface hardness to prevent abrasion, erosion, and corrosion rather than thermal insulation. The fundamental mechanism of TBCs involves low thermal conductivity, phase stability at high temperatures, and strong adherence to the substrate, enabling protection in environments exceeding 1200degC.

Fundamentals of Wear-Resistant Coatings

Wear-resistant coatings are engineered to enhance surface durability by reducing material degradation caused by friction, abrasion, and erosion, typically composed of hard materials like carbides, nitrides, or ceramics. Thermal barrier coatings, in contrast, primarily protect components from high temperatures by providing low thermal conductivity layers, often using materials such as yttria-stabilized zirconia. The fundamental mechanism of wear-resistant coatings involves increasing hardness and adhesion to substrates, ensuring extended service life in harsh mechanical environments without significant thermal insulation properties.

Key Material Properties: Thermal Insulation vs. Wear Protection

Thermal barrier coatings (TBCs) primarily provide excellent thermal insulation, featuring low thermal conductivity and high temperature stability to protect components from extreme heat. Wear-resistant coatings emphasize hardness, abrasion resistance, and toughness to extend the lifespan of parts subject to mechanical wear and friction. Material selection for TBCs often includes ceramics like yttria-stabilized zirconia, whereas wear-resistant coatings commonly use carbides or nitrides for superior surface durability.

Composition and Microstructure of TBCs vs. Wear-Resistant Coatings

Thermal barrier coatings (TBCs) primarily consist of ceramic materials such as yttria-stabilized zirconia (YSZ), characterized by a porous, columnar microstructure that provides low thermal conductivity and high strain tolerance. In contrast, wear-resistant coatings are often composed of hard materials like carbides, nitrides, or borides, featuring dense, fine-grained microstructures that enhance hardness and abrasion resistance. The distinct compositions and microstructures directly influence their performance, with TBCs optimized for thermal insulation and wear-resistant coatings tailored for mechanical durability under frictional forces.

Deposition Techniques: TBCs vs. Wear-Resistant Coatings

Thermal barrier coatings (TBCs) are primarily deposited using plasma spraying and electron beam physical vapor deposition (EB-PVD), techniques that create highly porous and columnar microstructures essential for thermal insulation. Wear-resistant coatings commonly utilize methods like physical vapor deposition (PVD), chemical vapor deposition (CVD), and thermal spraying to achieve dense, hard surfaces optimized for abrasion and erosion resistance. The distinct deposition processes reflect the functional priorities of TBCs--thermal protection through low conductivity and structural stability--versus wear-resistant coatings, which emphasize hardness and adhesion for prolonged surface durability.

Performance in High-Temperature and High-Wear Environments

Thermal barrier coatings (TBCs) excel in high-temperature environments by providing exceptional insulation, reducing substrate metal temperatures, and enhancing engine component lifespan in aerospace and power generation applications. Wear-resistant coatings prioritize hardness and toughness to minimize material loss due to abrasion, erosion, and mechanical wear in manufacturing, mining, and heavy machinery. In extreme conditions combining high heat and wear, advanced composite coatings integrating thermal barrier and wear-resistant properties deliver superior durability and performance.

Application Areas: Aerospace, Automotive, and Industrial Sectors

Thermal barrier coatings (TBCs) are extensively applied in aerospace for jet engine turbine blades and combustors to withstand extreme temperatures, enhancing performance and durability. In automotive industries, wear-resistant coatings protect engine components and transmission parts from friction and abrasion, improving lifespan and efficiency. Industrial sectors utilize thermal barrier coatings in gas turbines and heat exchangers to prevent thermal degradation, while wear-resistant coatings are crucial for machinery parts subject to heavy mechanical stress and surface wear.

Challenges and Future Trends in Surface Coating Technologies

Thermal barrier coatings face challenges such as thermal mismatch, oxidation resistance, and spallation under cyclic high temperatures, necessitating advanced ceramic compositions and multilayer structures to enhance durability. Wear-resistant coatings struggle with maintaining hardness and toughness balance while preventing material degradation under abrasive and corrosive environments, driving innovations in nanostructured materials and self-healing properties. Future trends emphasize multifunctional coatings integrating thermal insulation and wear resistance, leveraging additive manufacturing and AI-driven design to optimize performance and extend lifecycle in aerospace, automotive, and industrial applications.

Comparative Summary: Selecting the Right Coating for Engineering Applications

Thermal barrier coatings (TBCs) primarily protect components from high temperatures by insulating surfaces and reducing thermal degradation, making them essential in aerospace and power generation industries. Wear-resistant coatings enhance surface hardness and reduce abrasion, erosion, and friction, improving durability in heavy machinery and automotive parts. Selecting the right coating depends on operating conditions: TBCs are optimal for thermal insulation under extreme heat, while wear-resistant coatings are ideal for mechanical stress and surface wear environments.

Thermal conductivity mismatch

Thermal barrier coatings exhibit low thermal conductivity to minimize heat transfer, whereas wear-resistant coatings often have higher thermal conductivity, creating a mismatch that can induce thermal stresses and affect coating performance.

Oxidation resistance

Thermal barrier coatings provide superior oxidation resistance by forming stable oxide layers at high temperatures, whereas wear-resistant coatings primarily focus on mechanical durability with limited oxidation protection.

Erosion protection

Thermal barrier coatings primarily protect against high-temperature erosion by insulating surfaces, while wear-resistant coatings enhance erosion resistance through hard, durable materials that prevent material loss from abrasive particles.

CMAS infiltration

Thermal barrier coatings exhibit superior resistance to CMAS infiltration compared to wear-resistant coatings, enhancing durability in high-temperature environments.

Hot corrosion stability

Thermal barrier coatings exhibit superior hot corrosion stability by providing high-temperature oxidation resistance and thermal insulation, whereas wear-resistant coatings primarily enhance mechanical durability with comparatively lower corrosion resistance at elevated temperatures.

Abrasive wear rate

Thermal barrier coatings typically exhibit lower abrasive wear rates compared to wear-resistant coatings due to their ceramic composition and heat-insulating properties.

Bond coat integrity

Thermal barrier coatings rely on bond coat integrity to prevent oxidation and ensure thermal insulation, whereas wear-resistant coatings prioritize bond coat strength to withstand mechanical abrasion and extend surface durability.

Micro-cracking resilience

Thermal barrier coatings exhibit superior micro-cracking resilience compared to wear-resistant coatings due to their enhanced thermal expansion compatibility and fracture toughness.

Thermal cycling fatigue

Thermal barrier coatings significantly enhance resistance to thermal cycling fatigue by insulating components from high temperatures, whereas wear-resistant coatings primarily protect against mechanical abrasion without substantial improvement in thermal fatigue life.

Surface roughness retention

Thermal barrier coatings maintain superior surface roughness retention under high-temperature conditions compared to wear-resistant coatings, which excel primarily in mechanical abrasion environments.

Thermal barrier coatings vs Wear-resistant coatings Infographic

njnir.com

njnir.com