Triboelectric nanogenerators (TENGs) harness mechanical energy through contact electrification and electrostatic induction, offering high output voltage and flexibility for various materials. Piezoelectric nanogenerators (PENGs) convert mechanical stress into electrical energy via the piezoelectric effect, providing stable and linear output suitable for precision sensing applications. TENGs typically excel in harvesting low-frequency mechanical energy with simple fabrication, while PENGs deliver consistent power under dynamic mechanical loading with enhanced durability.

Table of Comparison

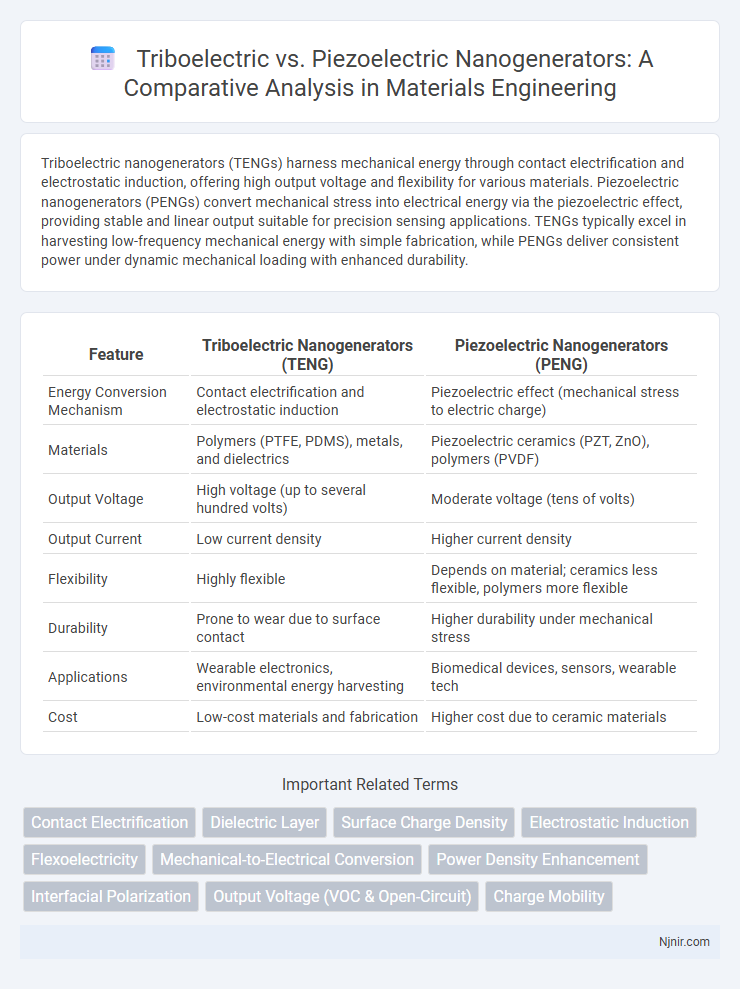

| Feature | Triboelectric Nanogenerators (TENG) | Piezoelectric Nanogenerators (PENG) |

|---|---|---|

| Energy Conversion Mechanism | Contact electrification and electrostatic induction | Piezoelectric effect (mechanical stress to electric charge) |

| Materials | Polymers (PTFE, PDMS), metals, and dielectrics | Piezoelectric ceramics (PZT, ZnO), polymers (PVDF) |

| Output Voltage | High voltage (up to several hundred volts) | Moderate voltage (tens of volts) |

| Output Current | Low current density | Higher current density |

| Flexibility | Highly flexible | Depends on material; ceramics less flexible, polymers more flexible |

| Durability | Prone to wear due to surface contact | Higher durability under mechanical stress |

| Applications | Wearable electronics, environmental energy harvesting | Biomedical devices, sensors, wearable tech |

| Cost | Low-cost materials and fabrication | Higher cost due to ceramic materials |

Introduction to Nanogenerators in Energy Harvesting

Triboelectric nanogenerators (TENGs) and piezoelectric nanogenerators (PENGs) are pivotal in energy harvesting, converting mechanical energy into electrical energy at the nanoscale. TENGs operate based on contact electrification and electrostatic induction, offering high voltage output and flexibility in material choice, while PENGs rely on the piezoelectric effect in crystalline materials to generate charge under mechanical stress with high current density. Both nanogenerators are essential for powering self-sustained microsystems and wearable electronics by harnessing ambient mechanical motions.

Fundamentals of Triboelectric Nanogenerators

Triboelectric nanogenerators (TENGs) convert mechanical energy into electrical energy through contact electrification and electrostatic induction, leveraging differences in electron affinity between materials. Unlike piezoelectric nanogenerators (PENGs) that rely on the piezoelectric effect in non-centrosymmetric crystals to generate charge under mechanical stress, TENGs utilize surface charge transfer when two different materials repeatedly contact and separate. The fundamental mechanism of TENGs involves the buildup of triboelectric charges on dielectric surfaces, which induces a potential difference and drives electron flow in an external circuit, enabling energy harvesting from various mechanical sources.

Working Principles of Piezoelectric Nanogenerators

Piezoelectric nanogenerators operate based on the direct piezoelectric effect, where mechanical stress applied to piezoelectric materials induces an electric charge due to the displacement of ions within the crystal lattice. This charge generation is proportional to the applied strain, enabling energy harvesting from mechanical vibrations or pressure. Unlike triboelectric nanogenerators that rely on contact electrification and charge transfer between different materials, piezoelectric nanogenerators focus on the intrinsic polarization changes within the material structure.

Material Selection for TENG and PENG Devices

Triboelectric nanogenerators (TENGs) primarily utilize polymers such as polytetrafluoroethylene (PTFE) and polyvinylidene fluoride (PVDF) for their high electronegativity, while piezoelectric nanogenerators (PENGs) frequently incorporate materials like zinc oxide (ZnO) nanowires and lead zirconate titanate (PZT) for their efficient piezoelectric properties. Material selection in TENG devices emphasizes surface charge density and triboelectric series positioning to maximize charge transfer, whereas PENG devices focus on crystal structure and piezoelectric coefficients to optimize mechanical-to-electrical energy conversion. Both technologies benefit from nanostructuring and hybrid composites, but TENGs prioritize charge generation through contact electrification, and PENGs rely on mechanical strain-induced polarization.

Fabrication Techniques: Comparisons and Challenges

Triboelectric nanogenerators (TENGs) typically utilize straightforward fabrication methods such as layer-by-layer assembly and contact separation with polymers and conductive materials, offering flexibility in material selection but facing challenges in durability and surface wear. Piezoelectric nanogenerators (PENGs) often require more complex fabrication techniques like electrospinning, chemical vapor deposition, or sol-gel processes to create nanostructured piezoelectric materials, resulting in higher structural precision but increased production cost and complexity. Both TENGs and PENGs encounter challenges in scaling up for mass production while maintaining high output performance and mechanical stability.

Performance Metrics and Output Characteristics

Triboelectric nanogenerators (TENGs) exhibit high voltage outputs typically ranging from hundreds to thousands of volts, while piezoelectric nanogenerators (PENGs) generate lower voltage outputs but higher current densities due to their intrinsic material properties. In terms of energy conversion efficiency, TENGs achieve values up to 50% under optimized conditions, benefiting from surface charge density and contact area enhancement, whereas PENGs can reach efficiencies around 30% depending on the piezoelectric coefficients of materials like PZT or ZnO. Frequency response differs significantly, with TENGs performing well under low-frequency mechanical stimuli (<10 Hz) and PENGs demonstrating consistent output at higher frequencies, supporting applications in diverse vibration environments.

Durability and Mechanical Reliability

Triboelectric nanogenerators (TENGs) exhibit higher durability under repeated mechanical stress due to their reliance on contact electrification and electrostatic induction without requiring material deformation. Piezoelectric nanogenerators (PENGs) often face mechanical fatigue over time as continuous strain leads to material degradation in piezoelectric layers. TENGs maintain stable energy output and mechanical reliability in dynamic environments longer than PENGs, making them suitable for long-term wearable and flexible electronic applications.

Application Scenarios: From Wearables to IoT

Triboelectric nanogenerators (TENGs) excel in harvesting biomechanical energy from human motion, making them ideal for wearable devices that monitor health and fitness metrics. Piezoelectric nanogenerators (PENGs) are effectively integrated into IoT sensors for structural health monitoring and environmental data collection due to their stability and sensitivity. Both technologies enable self-powered systems, but TENGs are preferred for low-frequency, large-deformation scenarios, whereas PENGs perform well in high-frequency vibration environments.

Environmental Impact and Scalability

Triboelectric nanogenerators (TENGs) exhibit lower environmental impact due to their utilization of abundant, non-toxic materials such as polymers and organic composites, whereas piezoelectric nanogenerators (PENGs) often rely on rare or hazardous elements like lead zirconate titanate (PZT). TENGs demonstrate superior scalability potential through their simple fabrication processes and compatibility with flexible substrates, enabling large-area applications with minimal energy consumption. Conversely, PENG scalability is limited by complex manufacturing techniques and material brittleness, which hinder mass production and flexible device integration.

Future Prospects and Research Directions

Future prospects for triboelectric nanogenerators (TENGs) emphasize enhancing material durability and energy conversion efficiency through novel nanostructured surfaces and hybrid systems integration. Research directions for piezoelectric nanogenerators (PENGs) prioritize developing flexible, lead-free piezoelectric materials with higher power output for wearable electronics and biomedical applications. Both TENGs and PENGs are increasingly explored for scalable energy harvesting solutions in the Internet of Things (IoT) and self-powered sensor networks.

Contact Electrification

Triboelectric nanogenerators generate electricity through contact electrification by transferring charge between different materials upon contact and separation, whereas piezoelectric nanogenerators produce electric signals via mechanical deformation of piezoelectric crystals.

Dielectric Layer

The dielectric layer in triboelectric nanogenerators enhances charge separation through material electronegativity differences, whereas in piezoelectric nanogenerators, it primarily serves as an insulating barrier to optimize electric field distribution for mechanical-to-electrical energy conversion.

Surface Charge Density

Triboelectric nanogenerators exhibit higher surface charge density than piezoelectric nanogenerators, resulting in greater energy harvesting efficiency and sensitivity in converting mechanical energy to electrical energy.

Electrostatic Induction

Triboelectric nanogenerators generate electricity through contact electrification and electrostatic induction between different materials, whereas piezoelectric nanogenerators rely on the deformation-induced polarization of crystalline structures without involving electrostatic induction.

Flexoelectricity

Flexoelectricity enhances the energy conversion efficiency in triboelectric nanogenerators by leveraging strain gradients, unlike piezoelectric nanogenerators which rely solely on uniform mechanical stress-induced polarization.

Mechanical-to-Electrical Conversion

Triboelectric nanogenerators convert mechanical energy into electricity through contact electrification and electrostatic induction, while piezoelectric nanogenerators generate electrical charge by exploiting the deformation-induced polarization in piezoelectric materials.

Power Density Enhancement

Triboelectric nanogenerators exhibit power density enhancements up to 50% higher than piezoelectric nanogenerators due to their improved surface charge density and contact electrification mechanisms.

Interfacial Polarization

Triboelectric nanogenerators generate electricity through interfacial polarization caused by contact electrification between different materials, whereas piezoelectric nanogenerators rely on polarization induced by mechanical stress within non-centrosymmetric crystals.

Output Voltage (VOC & Open-Circuit)

Triboelectric nanogenerators typically achieve higher open-circuit voltages (VOC) ranging from hundreds to thousands of volts, whereas piezoelectric nanogenerators generally exhibit lower VOC values typically below 100 volts.

Charge Mobility

Triboelectric nanogenerators exhibit higher charge mobility due to surface charge transfer mechanisms, whereas piezoelectric nanogenerators rely on bulk polarization with comparatively lower charge mobility.

triboelectric nanogenerators vs piezoelectric nanogenerators Infographic

njnir.com

njnir.com