Green cement offers a sustainable alternative to traditional cement by reducing carbon emissions through the incorporation of eco-friendly materials like fly ash, slag, and recycled industrial by-products. This innovative approach minimizes the environmental impact of construction while maintaining comparable strength and durability to conventional Portland cement. Advances in green cement technology also enhance energy efficiency during production, contributing to lower overall carbon footprints in the building industry.

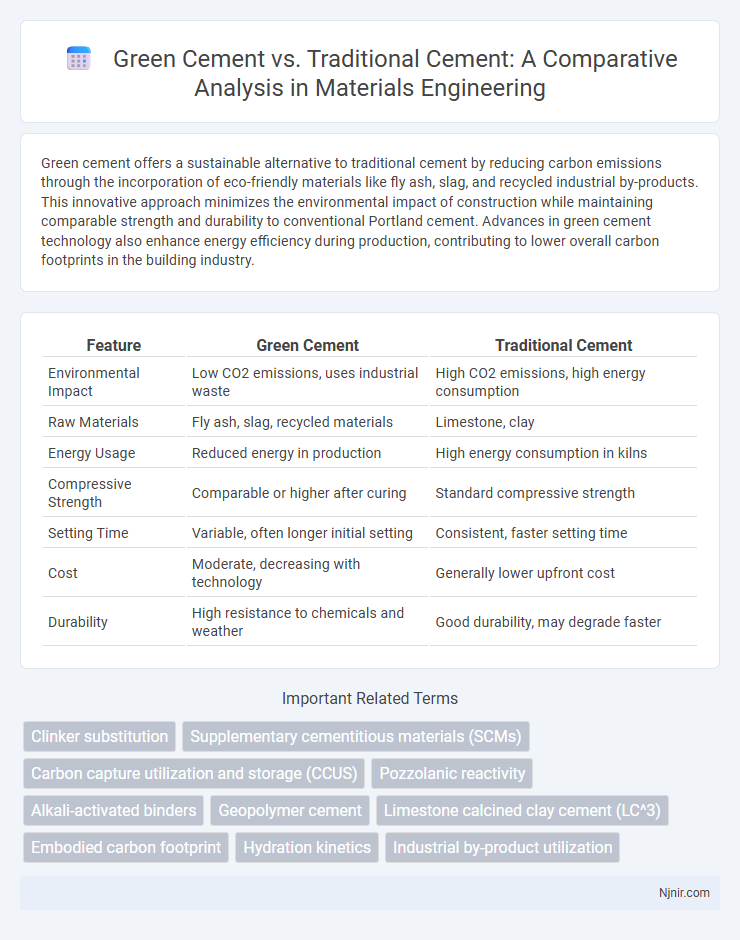

Table of Comparison

| Feature | Green Cement | Traditional Cement |

|---|---|---|

| Environmental Impact | Low CO2 emissions, uses industrial waste | High CO2 emissions, high energy consumption |

| Raw Materials | Fly ash, slag, recycled materials | Limestone, clay |

| Energy Usage | Reduced energy in production | High energy consumption in kilns |

| Compressive Strength | Comparable or higher after curing | Standard compressive strength |

| Setting Time | Variable, often longer initial setting | Consistent, faster setting time |

| Cost | Moderate, decreasing with technology | Generally lower upfront cost |

| Durability | High resistance to chemicals and weather | Good durability, may degrade faster |

Introduction to Green Cement and Traditional Cement

Green cement, formulated with sustainable materials such as industrial byproducts like fly ash and slag, reduces carbon emissions by up to 30% compared to traditional Portland cement. Traditional cement relies heavily on limestone calcination, contributing approximately 8% of global CO2 emissions due to energy-intensive production processes. The adoption of green cement addresses environmental concerns by enhancing durability and lowering the carbon footprint of construction projects.

Composition and Raw Materials Comparison

Green cement incorporates eco-friendly raw materials such as fly ash, slag, and natural pozzolans, reducing reliance on traditional limestone and clay. This alternative composition lowers carbon dioxide emissions by utilizing industrial by-products and waste materials, enhancing sustainability. Traditional cement primarily consists of clinker produced by heating limestone and clay, resulting in higher energy consumption and increased greenhouse gas emissions.

Environmental Impact: Carbon Footprint Analysis

Green cement significantly reduces carbon emissions by utilizing alternative raw materials and lower-temperature production methods, cutting CO2 output by up to 40% compared to traditional Portland cement. Traditional cement manufacturing accounts for approximately 8% of global CO2 emissions due to the energy-intensive calcination process and fossil fuel combustion. Lifecycle assessments confirm green cement's potential to mitigate environmental impact, promoting sustainable construction and aligning with global carbon reduction targets.

Energy Consumption in Manufacturing Processes

Green cement manufacturing consumes significantly less energy compared to traditional cement, primarily due to the use of alternative raw materials and lower kiln temperatures. The reduction in energy consumption can reach up to 30%, resulting in decreased carbon emissions and a smaller environmental footprint. Innovations such as supplementary cementitious materials and optimized production techniques contribute to this improved energy efficiency in green cement production.

Mechanical Properties and Performance

Green cement exhibits comparable or enhanced mechanical properties compared to traditional cement, including higher compressive strength and improved durability. Its performance benefits from incorporating supplementary cementitious materials like fly ash or slag, which reduce permeability and increase resistance to chemical attacks. These characteristics make green cement a sustainable alternative without compromising structural integrity in construction applications.

Durability and Longevity Assessment

Green cement demonstrates enhanced durability and longevity compared to traditional cement due to its lower carbon footprint and incorporation of supplementary cementitious materials like fly ash and slag, which improve resistance to chemical attack and reduce permeability. Studies indicate green cement mixtures exhibit superior performance in sulfate-rich environments and better long-term strength retention, contributing to extended structural lifespan. These durability benefits reduce maintenance costs and environmental impact, making green cement a sustainable alternative in infrastructure applications.

Cost Considerations and Economic Feasibility

Green cement often incurs higher initial production costs due to the use of alternative raw materials and energy-efficient technologies, leading to increased manufacturing expenses compared to traditional cement. However, its long-term economic feasibility improves through reduced carbon taxes, lower energy consumption, and potential government incentives promoting sustainable construction practices. Investing in green cement can result in cost savings over the lifespan of a project by minimizing environmental impact and enhancing compliance with evolving regulatory standards.

Regulatory Standards and Certifications

Green cement complies with stringent environmental regulatory standards such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), ensuring reduced carbon emissions and sustainable raw material sourcing. Traditional cement often meets standard building codes but lacks certifications targeting environmental impact or carbon footprint reduction. Key certifications like CEM II/A-LL and ASTM C1157 incorporate requirements for performance and environmental metrics, positioning green cement as a preferred choice in eco-conscious construction projects.

Applications in Modern Construction

Green cement, characterized by reduced carbon emissions and eco-friendly materials like industrial byproducts, is increasingly used in sustainable building projects such as green roofs, energy-efficient homes, and infrastructure requiring lower environmental impact. Traditional cement remains dominant for high-strength applications like bridges, highways, and heavy-load structures due to its proven durability and availability. Innovations in green cement formulations now enable comparable performance in modern construction sectors prioritizing sustainability without compromising structural integrity.

Future Trends in Cement Technology

Green cement innovations prioritize reducing carbon emissions by incorporating alternative materials such as fly ash, slag, and bio-based additives, enhancing sustainability in construction. Future trends highlight the integration of carbon capture and utilization technologies, enabling cement plants to recycle CO2 emissions and produce carbon-neutral composites. Advances in nanotechnology and 3D printing further optimize the strength and durability of green cement, promoting resource efficiency and longer-lasting infrastructure.

Clinker substitution

Green cement reduces environmental impact by substituting up to 50% of traditional clinker with industrial by-products like fly ash and slag, lowering CO2 emissions compared to traditional cement.

Supplementary cementitious materials (SCMs)

Green cement utilizes Supplementary Cementitious Materials (SCMs) like fly ash, slag, and silica fume to reduce clinker content, lower CO2 emissions, and enhance durability compared to traditional cement.

Carbon capture utilization and storage (CCUS)

Green cement integrates advanced Carbon Capture Utilization and Storage (CCUS) technologies to significantly reduce CO2 emissions compared to traditional cement production, enhancing sustainability in construction.

Pozzolanic reactivity

Green cement demonstrates enhanced pozzolanic reactivity compared to traditional cement due to its higher content of supplementary cementitious materials like fly ash and slag, which improve durability and reduce CO2 emissions.

Alkali-activated binders

Alkali-activated binders in green cement significantly reduce carbon emissions and enhance durability compared to traditional Portland cement, making them a sustainable alternative in construction.

Geopolymer cement

Geopolymer cement, a sustainable alternative to traditional Portland cement, significantly reduces carbon emissions by utilizing industrial byproducts like fly ash and slag, offering enhanced durability and lower environmental impact.

Limestone calcined clay cement (LC^3)

Limestone calcined clay cement (LC^3) reduces CO2 emissions by up to 30% compared to traditional cement while maintaining comparable strength and durability, making it a sustainable alternative in the construction industry.

Embodied carbon footprint

Green cement reduces the embodied carbon footprint by up to 40-60% compared to traditional cement, significantly lowering greenhouse gas emissions in construction.

Hydration kinetics

Green cement exhibits slower hydration kinetics than traditional cement due to its alternative binder materials and reduced clinker content, resulting in lower early strength but enhanced long-term durability and reduced CO2 emissions.

Industrial by-product utilization

Green cement reduces environmental impact by incorporating industrial by-products like fly ash and slag to replace traditional clinker, enhancing sustainability in construction materials.

Green Cement vs Traditional Cement Infographic

njnir.com

njnir.com