Spark plasma sintering (SPS) enables rapid densification of materials through pulsed electric current and uniaxial pressure, resulting in finer microstructures and enhanced mechanical properties compared to hot pressing. Hot pressing relies on sustained high temperature and pressure to densify powders, often leading to grain growth and longer processing times. SPS technology offers superior control over microstructural evolution, making it ideal for advanced ceramics and composite materials where precision and performance are critical.

Table of Comparison

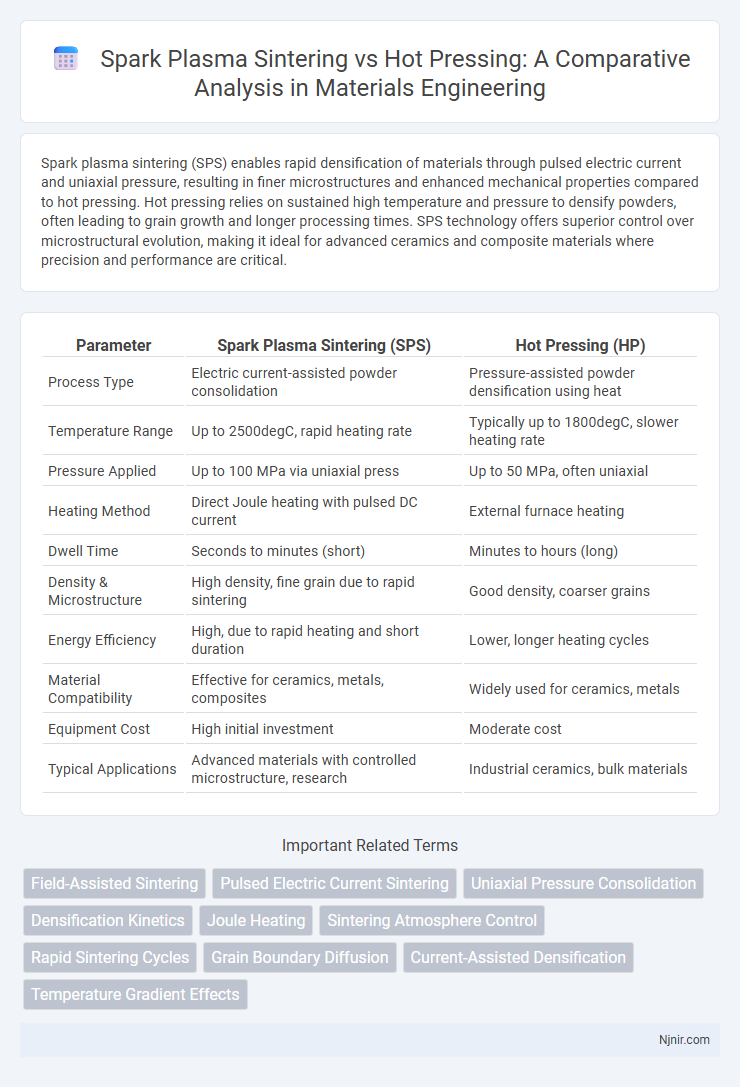

| Parameter | Spark Plasma Sintering (SPS) | Hot Pressing (HP) |

|---|---|---|

| Process Type | Electric current-assisted powder consolidation | Pressure-assisted powder densification using heat |

| Temperature Range | Up to 2500degC, rapid heating rate | Typically up to 1800degC, slower heating rate |

| Pressure Applied | Up to 100 MPa via uniaxial press | Up to 50 MPa, often uniaxial |

| Heating Method | Direct Joule heating with pulsed DC current | External furnace heating |

| Dwell Time | Seconds to minutes (short) | Minutes to hours (long) |

| Density & Microstructure | High density, fine grain due to rapid sintering | Good density, coarser grains |

| Energy Efficiency | High, due to rapid heating and short duration | Lower, longer heating cycles |

| Material Compatibility | Effective for ceramics, metals, composites | Widely used for ceramics, metals |

| Equipment Cost | High initial investment | Moderate cost |

| Typical Applications | Advanced materials with controlled microstructure, research | Industrial ceramics, bulk materials |

Introduction to Sintering Techniques in Materials Engineering

Spark plasma sintering (SPS) and hot pressing are advanced sintering techniques widely used in materials engineering to densify powders into solid components with enhanced properties. SPS employs a pulsed electric current and uniaxial pressure to achieve rapid heating rates and shorter sintering times, resulting in finer microstructures and improved mechanical performance compared to traditional hot pressing. Hot pressing involves simultaneous application of heat and pressure over extended durations, promoting diffusion and densification but often leading to grain growth and longer processing cycles.

Fundamentals of Spark Plasma Sintering (SPS)

Spark Plasma Sintering (SPS) utilizes a pulsed direct current passing through graphite dies and powder compact, generating Joule heating internally for rapid densification. Unlike hot pressing, which relies primarily on external heat and uniaxial pressure, SPS combines electrical and mechanical energy to activate sintering at lower temperatures and shorter times. The fundamental mechanism involves enhanced diffusion and plasma discharges at particle contacts, promoting efficient grain boundary bonding and microstructural control.

Principles and Process of Hot Pressing

Hot pressing involves applying uniaxial pressure and elevated temperature simultaneously to densify powders through solid-state diffusion and plastic deformation. The process typically occurs in a furnace with a graphite or ceramic die, where pressure ranging from 10 to 100 MPa is maintained while heating above the material's recrystallization temperature. This method produces near-full-density materials with controlled grain growth, suitable for metals, ceramics, and composites.

Comparative Analysis: SPS vs. Hot Pressing

Spark Plasma Sintering (SPS) utilizes pulsed electric current to achieve rapid heating and densification, resulting in finer microstructures and shorter processing times compared to conventional hot pressing. Hot pressing applies uniaxial pressure and controlled heating, leading to longer sintering durations and coarser grain growth, which can affect mechanical properties. SPS generally offers superior control over grain size and phase distribution, making it preferable for advanced materials requiring precise microstructural characteristics.

Densification Mechanisms in SPS and Hot Pressing

Spark Plasma Sintering (SPS) utilizes rapid pulsed electric currents to directly heat powder particles, promoting enhanced mass transport mechanisms such as surface diffusion, activated grain boundary diffusion, and transient plasma effects that accelerate densification compared to hot pressing. Hot pressing relies primarily on external uniaxial pressure combined with high temperature, facilitating densification primarily through creep deformation and conventional solid-state diffusion without the aid of electric field effects. SPS achieves superior densification rates and finer microstructural control due to localized Joule heating and activated particle surfaces, whereas hot pressing generally requires longer dwell times and higher temperatures to attain comparable densities.

Processing Parameters and Their Effects

Spark plasma sintering (SPS) utilizes rapid heating rates of up to 1000degC/min and pulsed DC current, enabling lower sintering temperatures and shorter dwell times compared to hot pressing (HP), which relies on conductive heating with slower temperature ramp rates. SPS processing parameters such as applied pressure (typically 50-100 MPa), pulse duration, and atmosphere significantly influence densification, grain growth suppression, and phase stability, while HP requires higher temperatures and longer times to achieve comparable densification due to its reliance on external heating and mechanical pressure. Control over SPS parameters enhances microstructural homogeneity and mechanical properties by minimizing grain coarsening, whereas HP's extended thermal exposure can lead to undesired grain growth and reduced material performance.

Microstructural Evolution and Properties

Spark plasma sintering (SPS) enables rapid heating and cooling rates, resulting in finer grain sizes and enhanced densification compared to hot pressing, which typically experiences slower thermal cycles leading to coarser microstructures. The pulsed electric current in SPS promotes accelerated diffusion and neck formation between particles, improving mechanical properties such as hardness and fracture toughness. Hot pressing relies primarily on applied pressure and temperature over extended times, often causing grain growth that can reduce the strength and wear resistance of the final material.

Advantages and Limitations of SPS and Hot Pressing

Spark Plasma Sintering (SPS) offers rapid heating rates and precise temperature control, enabling the densification of materials at lower temperatures and shorter cycle times compared to Hot Pressing, which is beneficial for preserving fine microstructures. SPS demonstrates superior ability to produce ultrafine-grained and nanostructured materials with reduced grain growth, but its equipment cost and sample size limitations may constrain industrial-scale production. Hot Pressing allows for processing larger samples and exhibits simpler equipment requirements, though it typically requires longer sintering times and higher temperatures, leading to potential grain coarsening and less control over microstructural uniformity.

Applications in Advanced Material Synthesis

Spark plasma sintering (SPS) enables rapid densification of advanced materials, such as ceramics and composites, by applying pulsed electric current and uniaxial pressure, preserving fine microstructures that enhance mechanical properties. Hot pressing relies on prolonged high-temperature and pressure exposure, suitable for producing dense materials like superalloys and cemented carbides but often results in grain growth and reduced performance. SPS is preferred in synthesizing nanostructured materials and functionally graded components for aerospace, electronics, and biomedical applications due to its precise control over sintering parameters and shorter processing times.

Future Prospects and Emerging Trends

Spark plasma sintering (SPS) is advancing rapidly due to its ability to produce fine-grained, high-density materials at lower temperatures and shorter processing times compared to hot pressing. Future prospects highlight increased integration of in-situ monitoring techniques and hybrid approaches combining SPS with additive manufacturing to tailor microstructures and enhance material properties. Emerging trends emphasize scalability improvements and the development of multifunctional composites for aerospace, biomedical, and energy storage applications.

Field-Assisted Sintering

Field-assisted sintering in spark plasma sintering offers rapid densification and enhanced microstructural control compared to traditional hot pressing methods.

Pulsed Electric Current Sintering

Pulsed Electric Current Sintering (PECS), a form of spark plasma sintering, uses rapid electric current pulses to achieve faster densification and finer microstructures compared to conventional hot pressing methods.

Uniaxial Pressure Consolidation

Spark plasma sintering achieves faster uniaxial pressure consolidation than hot pressing due to its pulsed electric current enhancing particle diffusion and reducing sintering time.

Densification Kinetics

Spark plasma sintering achieves faster densification kinetics than hot pressing by utilizing pulsed electric currents and rapid heating rates to enhance mass transport and reduce sintering time.

Joule Heating

Spark plasma sintering utilizes rapid Joule heating through pulsed electric currents to achieve uniform temperature distribution and faster densification compared to the slower, conduction-based heating in traditional hot pressing.

Sintering Atmosphere Control

Spark plasma sintering offers superior sintering atmosphere control by enabling rapid heating in a controlled vacuum or inert gas environment, minimizing oxidation and contamination compared to conventional hot pressing methods.

Rapid Sintering Cycles

Spark plasma sintering achieves rapid sintering cycles by using pulsed electric currents to generate localized heating and apply pressure simultaneously, resulting in faster densification compared to the longer thermal cycles required in conventional hot pressing.

Grain Boundary Diffusion

Spark plasma sintering enhances grain boundary diffusion through rapid localized heating and high heating rates, resulting in finer microstructures compared to the slower, uniform temperature profile of conventional hot pressing.

Current-Assisted Densification

Current-assisted densification in spark plasma sintering achieves faster heating rates and uniform temperature distribution compared to hot pressing, resulting in superior microstructural control and enhanced material properties.

Temperature Gradient Effects

Spark plasma sintering exhibits lower temperature gradient effects compared to hot pressing, resulting in more uniform microstructure and enhanced densification in sintered materials.

spark plasma sintering vs hot pressing Infographic

njnir.com

njnir.com