Phase change materials excel in storing and releasing thermal energy through reversible phase transitions, making them ideal for applications requiring efficient heat management and temperature regulation. Thermoelectric materials convert temperature differences directly into electrical voltage, offering sustainable solutions for power generation and solid-state cooling. Both materials present unique advantages in energy efficiency, with phase change materials optimizing thermal storage and thermoelectric materials enabling energy conversion without moving parts.

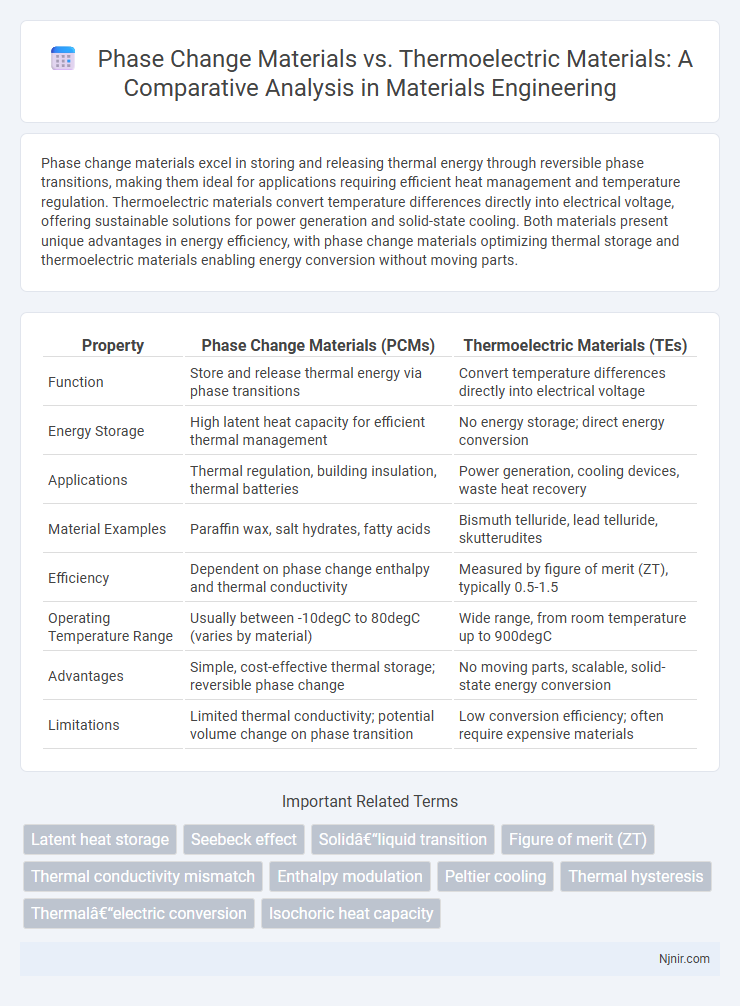

Table of Comparison

| Property | Phase Change Materials (PCMs) | Thermoelectric Materials (TEs) |

|---|---|---|

| Function | Store and release thermal energy via phase transitions | Convert temperature differences directly into electrical voltage |

| Energy Storage | High latent heat capacity for efficient thermal management | No energy storage; direct energy conversion |

| Applications | Thermal regulation, building insulation, thermal batteries | Power generation, cooling devices, waste heat recovery |

| Material Examples | Paraffin wax, salt hydrates, fatty acids | Bismuth telluride, lead telluride, skutterudites |

| Efficiency | Dependent on phase change enthalpy and thermal conductivity | Measured by figure of merit (ZT), typically 0.5-1.5 |

| Operating Temperature Range | Usually between -10degC to 80degC (varies by material) | Wide range, from room temperature up to 900degC |

| Advantages | Simple, cost-effective thermal storage; reversible phase change | No moving parts, scalable, solid-state energy conversion |

| Limitations | Limited thermal conductivity; potential volume change on phase transition | Low conversion efficiency; often require expensive materials |

Introduction to Advanced Functional Materials

Phase change materials (PCMs) and thermoelectric materials are pivotal in advanced functional materials for energy efficiency and thermal management. PCMs store and release thermal energy through reversible solid-liquid transitions, enabling applications in thermal regulation, energy storage, and temperature control. Thermoelectric materials convert temperature gradients directly into electrical energy or vice versa, offering sustainable solutions for power generation and refrigeration with high conversion efficiency.

Overview of Phase Change Materials (PCMs)

Phase Change Materials (PCMs) store and release thermal energy during the process of melting and solidifying at specific temperatures, making them highly effective for thermal energy storage applications. Common PCMs include paraffin waxes, salt hydrates, and fatty acids, each selected based on melting point, latent heat, and thermal conductivity. Their ability to maintain nearly constant temperatures during phase transitions enables efficient thermal management in building materials, electronics cooling, and solar energy systems.

Overview of Thermoelectric Materials

Thermoelectric materials convert temperature differences directly into electrical voltage through the Seebeck effect, enabling energy harvesting and solid-state cooling applications. Common thermoelectric materials include bismuth telluride (Bi2Te3), lead telluride (PbTe), and silicon-germanium alloys, chosen for their high Seebeck coefficients, low thermal conductivity, and electrical conductivity. Advances in nanostructuring and doping techniques have significantly enhanced the figure of merit (ZT) of thermoelectric materials, improving their efficiency and commercial viability compared to traditional phase change materials used for thermal energy storage.

Mechanisms of Thermal Energy Storage in PCMs

Phase change materials (PCMs) store thermal energy by absorbing or releasing latent heat during phase transitions, typically between solid and liquid states. This mechanism enables high energy density and temperature regulation within narrow temperature ranges, making PCMs ideal for applications requiring efficient thermal management. Unlike thermoelectric materials that convert heat directly into electrical energy through the Seebeck effect, PCMs rely on reversible physical state changes to regulate and store thermal energy.

Principles of Thermoelectric Energy Conversion

Thermoelectric materials convert heat directly into electricity based on the Seebeck effect, where a temperature gradient induces charge carrier diffusion, generating voltage. Unlike phase change materials, which store thermal energy by changing states, thermoelectric devices rely on the movement of electrons or holes within semiconductors to enable energy conversion. Key parameters for thermoelectric efficiency include the Seebeck coefficient, electrical conductivity, and thermal conductivity, combined in the dimensionless figure of merit (ZT).

Material Properties: PCMs vs Thermoelectric Materials

Phase change materials (PCMs) exhibit high latent heat capacity, enabling efficient thermal energy storage through reversible phase transitions, typically between solid and liquid states. Thermoelectric materials, such as bismuth telluride and lead telluride, possess unique Seebeck coefficients and low thermal conductivity combined with high electrical conductivity, critical for direct heat-to-electricity conversion. The intrinsic difference lies in PCMs' ability to store heat versus thermoelectric materials' capability to convert temperature gradients into electrical energy, driven by their distinct electronic and thermal transport properties.

Applications in Thermal Management

Phase change materials (PCMs) and thermoelectric materials serve distinct roles in thermal management applications, where PCMs excel in passive heat storage and temperature regulation through latent heat absorption and release during phase transitions. Thermoelectric materials actively convert temperature gradients into electrical energy and vice versa, enabling precise heat pumping and power generation in cooling and heating systems. While PCMs are widely used in building climate control, electronics cooling, and thermal energy storage, thermoelectric materials find applications in waste heat recovery, spacecraft thermal regulation, and compact solid-state refrigeration.

Efficiency and Performance Comparison

Phase change materials (PCMs) excel in thermal energy storage by absorbing and releasing large amounts of latent heat during phase transitions, offering high efficiency in thermal regulation but limited electrical energy conversion. Thermoelectric materials convert temperature gradients directly into electrical energy with performance measured by the dimensionless figure of merit (ZT), where higher ZT values indicate better efficiency, typically ranging between 1 and 3 for advanced materials. While PCMs provide effective thermal buffering in applications like building climate control and thermal management, thermoelectric materials are preferred for waste heat recovery and power generation due to their direct electricity conversion capabilities despite generally lower thermal energy storage capacity.

Current Challenges and Technological Limitations

Phase change materials face challenges such as limited thermal cycling stability and slow response times, which hinder their efficiency in rapid energy storage and release applications. Thermoelectric materials struggle with low conversion efficiencies due to intrinsic material properties like high thermal conductivity and limited Seebeck coefficients, restricting their widespread adoption for power generation and cooling. Both materials require advancements in nanostructuring and composite engineering to overcome these technological limitations and improve performance metrics significantly.

Future Trends in Thermal Energy Materials

Future trends in thermal energy materials emphasize enhanced efficiency and multifunctionality in phase change materials (PCMs) and thermoelectric materials (TEs). Innovations in nano-engineering and hybrid composites aim to improve thermal conductivity and energy storage capacity in PCMs, while advanced thermoelectric materials target higher Seebeck coefficients and lower thermal conductivity for better energy conversion rates. Integration of both technologies into smart systems and wearable devices represents a significant direction for sustainable thermal management and energy harvesting solutions.

Latent heat storage

Phase change materials maximize latent heat storage by absorbing and releasing thermal energy during phase transitions, whereas thermoelectric materials convert temperature differences directly into electrical energy without storing latent heat.

Seebeck effect

Thermoelectric materials exploit the Seebeck effect to directly convert temperature differences into electrical voltage, whereas phase change materials primarily store and release thermal energy without generating electrical power.

Solid–liquid transition

Phase change materials leverage solid-liquid transitions to store and release thermal energy efficiently, while thermoelectric materials convert temperature gradients directly into electrical energy without phase changes.

Figure of merit (ZT)

Thermoelectric materials typically exhibit higher figure of merit (ZT) values around 1 to 2, enabling efficient direct heat-to-electricity conversion, while phase change materials primarily focus on latent heat storage with negligible ZT values.

Thermal conductivity mismatch

Phase change materials exhibit low thermal conductivity that enables efficient heat storage, whereas thermoelectric materials require optimized thermal conductivity to maintain temperature gradients for effective energy conversion.

Enthalpy modulation

Phase change materials exhibit significant enthalpy modulation through latent heat absorption and release during phase transitions, whereas thermoelectric materials rely on electron and phonon transport with minimal enthalpy change.

Peltier cooling

Phase change materials store and release latent heat for thermal regulation, while thermoelectric materials use the Peltier effect to convert electrical energy into precise solid-state cooling without moving parts.

Thermal hysteresis

Phase change materials exhibit significant thermal hysteresis due to latent heat during phase transitions, whereas thermoelectric materials show minimal thermal hysteresis, enabling more stable temperature-to-electricity conversion.

Thermal–electric conversion

Phase change materials store and release thermal energy through latent heat during phase transitions, while thermoelectric materials directly convert temperature gradients into electrical energy using the Seebeck effect for efficient thermal-electric conversion.

Isochoric heat capacity

Phase change materials exhibit significantly higher isochoric heat capacity due to latent heat absorption during phase transition compared to thermoelectric materials, which rely on electronic properties with relatively constant isochoric heat capacity.

Phase change materials vs Thermoelectric materials Infographic

njnir.com

njnir.com