Creep and fatigue are critical failure mechanisms in materials engineering that compromise structural integrity under different conditions. Creep refers to the time-dependent deformation occurring at constant stress and elevated temperatures, predominantly affecting components in high-temperature environments. Fatigue involves the progressive and localized structural damage caused by cyclic loading, leading to crack initiation and propagation even below the material's yield strength.

Table of Comparison

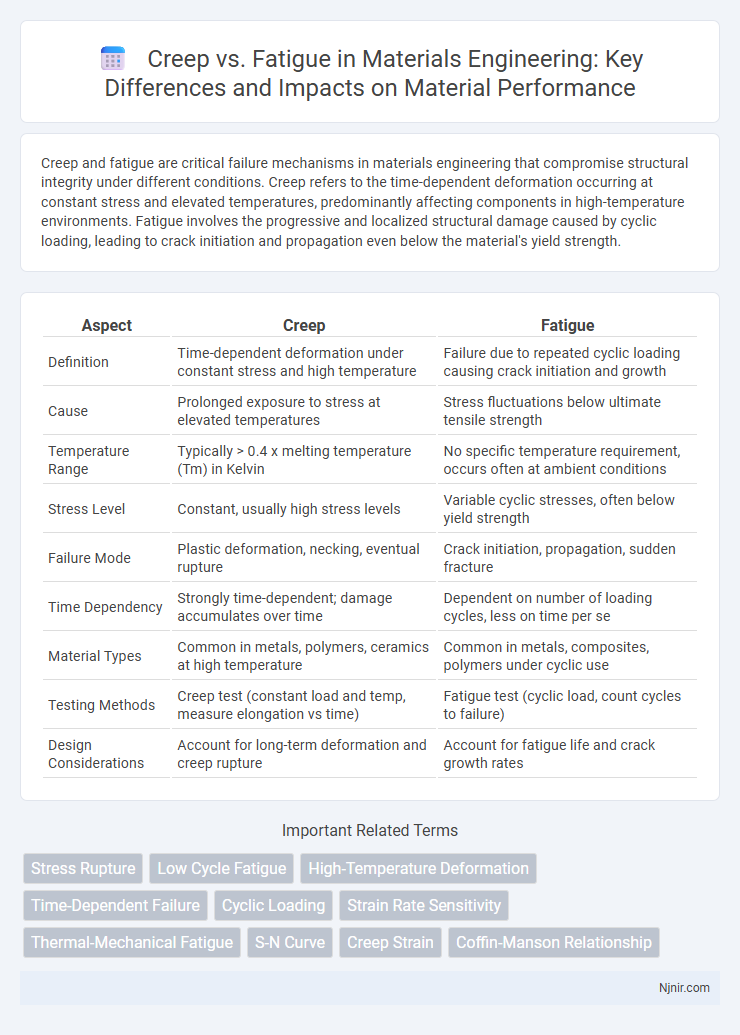

| Aspect | Creep | Fatigue |

|---|---|---|

| Definition | Time-dependent deformation under constant stress and high temperature | Failure due to repeated cyclic loading causing crack initiation and growth |

| Cause | Prolonged exposure to stress at elevated temperatures | Stress fluctuations below ultimate tensile strength |

| Temperature Range | Typically > 0.4 x melting temperature (Tm) in Kelvin | No specific temperature requirement, occurs often at ambient conditions |

| Stress Level | Constant, usually high stress levels | Variable cyclic stresses, often below yield strength |

| Failure Mode | Plastic deformation, necking, eventual rupture | Crack initiation, propagation, sudden fracture |

| Time Dependency | Strongly time-dependent; damage accumulates over time | Dependent on number of loading cycles, less on time per se |

| Material Types | Common in metals, polymers, ceramics at high temperature | Common in metals, composites, polymers under cyclic use |

| Testing Methods | Creep test (constant load and temp, measure elongation vs time) | Fatigue test (cyclic load, count cycles to failure) |

| Design Considerations | Account for long-term deformation and creep rupture | Account for fatigue life and crack growth rates |

Introduction to Creep and Fatigue in Materials Engineering

Creep refers to the slow, time-dependent deformation of materials under constant stress, typically occurring at high temperatures relative to the material's melting point. Fatigue involves the progressive structural damage and eventual failure of materials caused by cyclic or fluctuating stresses over repeated loading cycles. Understanding both creep and fatigue is crucial in materials engineering for predicting long-term performance and ensuring the reliability of components in applications such as aerospace, power plants, and automotive industries.

Fundamental Definitions: Creep and Fatigue

Creep is the time-dependent, permanent deformation of a material under constant stress, typically occurring at high temperatures over prolonged periods. Fatigue involves the progressive structural damage and failure of materials subjected to cyclic or fluctuating stresses, even if these stresses are below the material's yield strength. Understanding these fundamental differences is essential for predicting material lifespan and ensuring structural integrity in engineering applications.

Microstructural Mechanisms of Creep

Creep deformation primarily involves microstructural mechanisms such as grain boundary sliding, diffusional flow, and dislocation creep, which occur under sustained high-temperature stress. These processes cause time-dependent plastic deformation as atoms migrate within the crystal lattice, driven by vacancy diffusion and dislocation movement along grain boundaries. Understanding these mechanisms is crucial for predicting material behavior in high-temperature applications, contrasting with fatigue where cyclic loading dominates microstructural damage through crack initiation and propagation.

Microstructural Mechanisms of Fatigue

Fatigue damage primarily originates from cyclic loading, inducing microstructural changes such as dislocation movement, formation of persistent slip bands, and microcrack initiation at grain boundaries or inclusions. These mechanisms differ from creep, which involves time-dependent deformation dominated by diffusion and grain boundary sliding under constant stress at elevated temperatures. Understanding fatigue microstructural evolution enables improved prediction of material lifespan and the development of alloys with enhanced resistance to crack initiation and propagation under repetitive stress.

Key Factors Influencing Creep Behavior

Temperature, applied stress, and material microstructure are key factors influencing creep behavior, as elevated temperatures accelerate atomic diffusion and dislocation movement. Creep resistance is strongly affected by grain size, with finer grains often reducing creep rates due to grain boundary strengthening, while larger grains can improve creep life in some alloys by minimizing boundary sliding. The presence of impurities, alloying elements, and the operating environment, including oxidation or corrosion, also significantly impact the creep deformation process.

Critical Factors Affecting Fatigue Life

Critical factors affecting fatigue life include stress concentration, load magnitude, and environmental conditions such as temperature and corrosion. Material properties like microstructure, grain size, and surface finish significantly influence crack initiation and propagation rates. Understanding these variables enables accurate prediction and enhancement of fatigue performance in engineering components.

Comparative Analysis: Creep vs Fatigue Failure

Creep failure occurs due to prolonged exposure to high stress and temperature, leading to time-dependent plastic deformation, while fatigue failure results from cyclic loading causing crack initiation and propagation over time. Creep typically dominates in high-temperature applications like turbine blades, whereas fatigue is prevalent in components subject to fluctuating stresses such as aircraft wings. Material selection and design strategies must consider these distinct failure mechanisms to enhance component durability and prevent unexpected breakdowns.

Testing Methods for Creep and Fatigue Properties

Creep testing methods involve subjecting a specimen to constant load or stress at elevated temperatures for extended periods to measure deformation and time to rupture, typically following ASTM E139 standards. Fatigue testing utilizes cyclic loading with controlled stress or strain amplitudes to evaluate material resistance to crack initiation and propagation, commonly performed according to ASTM E466 or ASTM E647 procedures. Both methods employ precise data acquisition systems to monitor strain, time, and number of cycles, enabling accurate assessment of long-term performance and durability under varying operational conditions.

Case Studies: Real-world Examples of Creep and Fatigue

Case studies reveal that creep significantly affected turbine blades in power plants, where prolonged exposure to high temperatures caused gradual deformation leading to failure. In aerospace, fatigue failure occurred in aircraft wings due to cyclic loading over flight missions, highlighting the critical role of fatigue analysis in structural integrity. Both phenomena emphasize the necessity for material selection and predictive maintenance in engineering applications.

Strategies for Mitigating Creep and Fatigue in Engineering Applications

Effective strategies for mitigating creep and fatigue in engineering applications include selecting high-performance materials such as nickel-based superalloys and titanium alloys known for their superior resistance to deformation and crack initiation. Implementing design improvements like reducing stress concentrations, optimizing component geometry, and employing surface treatments such as shot peening or coatings can significantly enhance durability. Monitoring operating conditions to maintain optimal temperature and load cycles, along with regular maintenance and non-destructive testing, ensures early detection and prevention of creep and fatigue failures.

Stress Rupture

Stress rupture is a critical failure mode in materials subjected to sustained high stress and temperature, where creep deformation leads to sudden fracture without significant plastic deformation.

Low Cycle Fatigue

Low cycle fatigue involves significant plastic deformation under cyclic loading, distinguishing it from creep which is time-dependent deformation under constant stress at elevated temperatures.

High-Temperature Deformation

High-temperature deformation primarily involves creep, a time-dependent strain under constant stress, whereas fatigue concerns failure from cyclic loading at elevated temperatures.

Time-Dependent Failure

Creep and fatigue represent time-dependent failure mechanisms where creep involves progressive deformation under constant stress at elevated temperatures, and fatigue results from crack initiation and growth under cyclic loading over time.

Cyclic Loading

Creep involves time-dependent deformation under constant load, while fatigue results from material failure due to repeated cyclic loading causing microscopic cracks.

Strain Rate Sensitivity

Strain rate sensitivity critically differentiates creep, characterized by time-dependent deformation at low strain rates, from fatigue, which involves cyclic loading effects with varying strain rates leading to material failure.

Thermal-Mechanical Fatigue

Thermal-mechanical fatigue combines cyclic mechanical strain and fluctuating thermal stresses, accelerating material degradation differently from creep, which involves time-dependent deformation under constant stress at high temperature.

S-N Curve

The S-N curve characterizes material fatigue behavior by plotting stress (S) against the number of cycles to failure (N), while creep involves time-dependent deformation under constant stress, making the S-N curve less applicable for creep analysis.

Creep Strain

Creep strain is the time-dependent permanent deformation occurring in materials subjected to constant stress at high temperatures, distinguishing it from fatigue which involves cyclic loading.

Coffin-Manson Relationship

The Coffin-Manson relationship describes the strain-life behavior in low-cycle fatigue, quantifying fatigue damage through plastic strain amplitude and number of reversals to failure in materials experiencing cyclic loading.

Creep vs Fatigue Infographic

njnir.com

njnir.com