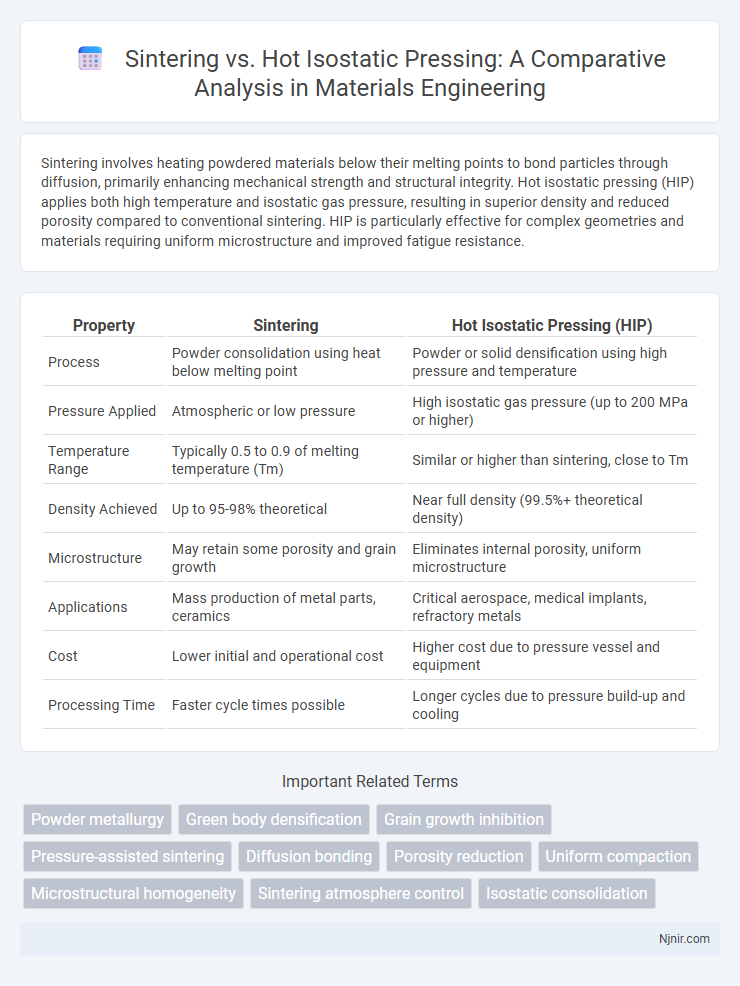

Sintering involves heating powdered materials below their melting points to bond particles through diffusion, primarily enhancing mechanical strength and structural integrity. Hot isostatic pressing (HIP) applies both high temperature and isostatic gas pressure, resulting in superior density and reduced porosity compared to conventional sintering. HIP is particularly effective for complex geometries and materials requiring uniform microstructure and improved fatigue resistance.

Table of Comparison

| Property | Sintering | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Process | Powder consolidation using heat below melting point | Powder or solid densification using high pressure and temperature |

| Pressure Applied | Atmospheric or low pressure | High isostatic gas pressure (up to 200 MPa or higher) |

| Temperature Range | Typically 0.5 to 0.9 of melting temperature (Tm) | Similar or higher than sintering, close to Tm |

| Density Achieved | Up to 95-98% theoretical | Near full density (99.5%+ theoretical density) |

| Microstructure | May retain some porosity and grain growth | Eliminates internal porosity, uniform microstructure |

| Applications | Mass production of metal parts, ceramics | Critical aerospace, medical implants, refractory metals |

| Cost | Lower initial and operational cost | Higher cost due to pressure vessel and equipment |

| Processing Time | Faster cycle times possible | Longer cycles due to pressure build-up and cooling |

Introduction to Consolidation Techniques in Materials Engineering

Sintering involves heating powdered materials below their melting point to bond particles through diffusion, creating a solid mass with enhanced mechanical properties. Hot Isostatic Pressing (HIP) applies high pressure and temperature uniformly in all directions to eliminate porosity and improve density and strength in metals and ceramics. Both techniques are fundamental consolidation methods in materials engineering for fabricating components with tailored microstructures and performance characteristics.

Fundamentals of Sintering

Sintering is a heat-based process that compacts and fuses powdered materials below their melting point, leveraging atomic diffusion to form solid structures with enhanced mechanical properties. It relies on mechanisms such as surface diffusion, grain boundary diffusion, and volume diffusion to reduce porosity and increase density. Compared to hot isostatic pressing, which uses high pressure and temperature simultaneously to achieve densification, sintering primarily depends on thermal energy and time for microstructural evolution.

Principles of Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) applies high temperature and isostatic gas pressure to densify materials and eliminate internal porosity, enhancing mechanical properties and structural integrity. Unlike conventional sintering that relies on partial melting and surface diffusion, HIP uses argon or nitrogen gas pressure uniformly from all directions to achieve near-theoretical density. HIP is especially effective for complex shapes, aerospace components, and superalloys because it can reduce residual stresses and improve microstructure homogeneity.

Comparative Mechanisms: Sintering vs Hot Isostatic Pressing

Sintering involves the bonding of powder particles through diffusion at elevated temperatures, primarily under uniaxial or atmospheric pressure, leading to densification and grain growth. Hot Isostatic Pressing (HIP) applies high temperature combined with isotropic gas pressure, usually argon, uniformly around the part, promoting superior densification and pore closure compared to sintering. The key distinction lies in HIP's ability to eliminate internal voids and achieve near-theoretical density without significant deformation, whereas sintering often results in residual porosity and anisotropic shrinkage.

Microstructural Evolution in Sintering and HIP

Microstructural evolution in sintering involves diffusion-driven neck growth and pore elimination, leading to grain coarsening and densification under thermal activation. In hot isostatic pressing (HIP), simultaneous application of high temperature and isostatic gas pressure promotes enhanced diffusion, resulting in accelerated densification and reduced porosity with finer, more uniform grain structures. HIP's controlled pressure environment yields superior mechanical properties by minimizing residual stresses and achieving near-theoretical densities compared to conventional sintering.

Mechanical Properties: Outcomes of Each Process

Sintering enhances mechanical properties by promoting particle bonding and reducing porosity, resulting in improved strength and hardness but often retains some residual porosity that can limit fatigue resistance. Hot isostatic pressing (HIP) applies high pressure and temperature uniformly, significantly reducing internal voids and producing near-full density materials with superior tensile strength, ductility, and fatigue life. The HIP process typically yields components with enhanced fracture toughness and consistent mechanical performance compared to conventional sintered parts.

Applications and Industry Preferences

Sintering is widely used in the automotive and aerospace industries for producing complex metal parts with high precision and cost efficiency, particularly in powder metallurgy applications. Hot isostatic pressing (HIP) is preferred in aerospace, medical implants, and tooling industries where enhanced mechanical properties and elimination of internal porosity are critical. While sintering suits mass production of components like gears and filters, HIP is favored for critical, high-performance parts requiring superior density and structural integrity.

Advantages and Limitations of Sintering

Sintering offers advantages such as lower processing costs, the ability to produce complex shapes with minimal deformation, and energy efficiency due to lower temperatures compared to hot isostatic pressing (HIP). However, sintering limitations include lower density and mechanical properties, potential for residual porosity, and less uniform microstructure control. In contrast, HIP can achieve near-full density and superior material strength by applying high pressure and temperature simultaneously.

Benefits and Drawbacks of Hot Isostatic Pressing

Hot Isostatic Pressing (HIP) offers superior densification and uniform microstructure by applying high pressure and temperature, eliminating internal porosity commonly found in sintered parts. This process enhances mechanical properties such as strength, fatigue resistance, and isotropy compared to traditional sintering, making it ideal for critical aerospace and medical components. However, HIP involves higher operational costs, longer cycle times, and requires specialized equipment, limiting its use to high-value or complex geometries.

Future Trends and Innovations in Consolidation Processing

Future trends in consolidation processing emphasize the integration of advanced additive manufacturing techniques with sintering and hot isostatic pressing (HIP) to enhance microstructural control and mechanical properties. Innovations include the development of hybrid processes combining selective laser melting with subsequent HIP to reduce porosity and improve density in aerospace and biomedical components. Emerging research also focuses on optimizing sintering atmospheres and HIP parameters through machine learning algorithms to accelerate material development cycles and reduce energy consumption.

Powder metallurgy

Hot isostatic pressing enhances powder metallurgy by applying uniform pressure and high temperature simultaneously, resulting in superior densification and mechanical properties compared to conventional sintering.

Green body densification

Hot isostatic pressing achieves superior green body densification compared to sintering by applying uniform high-pressure gas alongside elevated temperatures, resulting in reduced porosity and enhanced mechanical properties.

Grain growth inhibition

Hot isostatic pressing effectively inhibits grain growth by applying uniform pressure and temperature, resulting in finer microstructures compared to conventional sintering.

Pressure-assisted sintering

Pressure-assisted sintering, including hot isostatic pressing, enhances densification and mechanical properties by applying high pressure and temperature uniformly, reducing porosity and improving material performance compared to conventional sintering.

Diffusion bonding

Diffusion bonding in sintering relies on solid-state atomic diffusion under moderate pressure and temperature, whereas hot isostatic pressing enhances diffusion bonding by applying uniform high pressure and temperature to eliminate porosity and improve material density.

Porosity reduction

Hot isostatic pressing significantly reduces porosity in metals and ceramics by applying high pressure and temperature uniformly, outperforming conventional sintering methods.

Uniform compaction

Hot isostatic pressing achieves more uniform compaction than sintering by applying high pressure isotropically, resulting in reduced porosity and enhanced material density.

Microstructural homogeneity

Hot isostatic pressing achieves superior microstructural homogeneity compared to sintering by applying uniform pressure and heat, resulting in reduced porosity and enhanced grain uniformity.

Sintering atmosphere control

Precise sintering atmosphere control is crucial for preventing oxidation and ensuring uniform densification, whereas hot isostatic pressing relies on high-pressure inert gas environments to eliminate porosity and enhance mechanical properties.

Isostatic consolidation

Hot isostatic pressing achieves superior isostatic consolidation by applying uniform high pressure and temperature simultaneously, resulting in improved material density and mechanical properties compared to conventional sintering.

sintering vs hot isostatic pressing Infographic

njnir.com

njnir.com