Advanced ceramics exhibit superior mechanical strength, thermal stability, and chemical resistance compared to traditional ceramics, making them ideal for high-performance applications. Innovations in processing techniques enable precise control of microstructure, enhancing properties such as toughness and wear resistance. Their use spans aerospace, electronics, and biomedical fields where reliability and durability are critical.

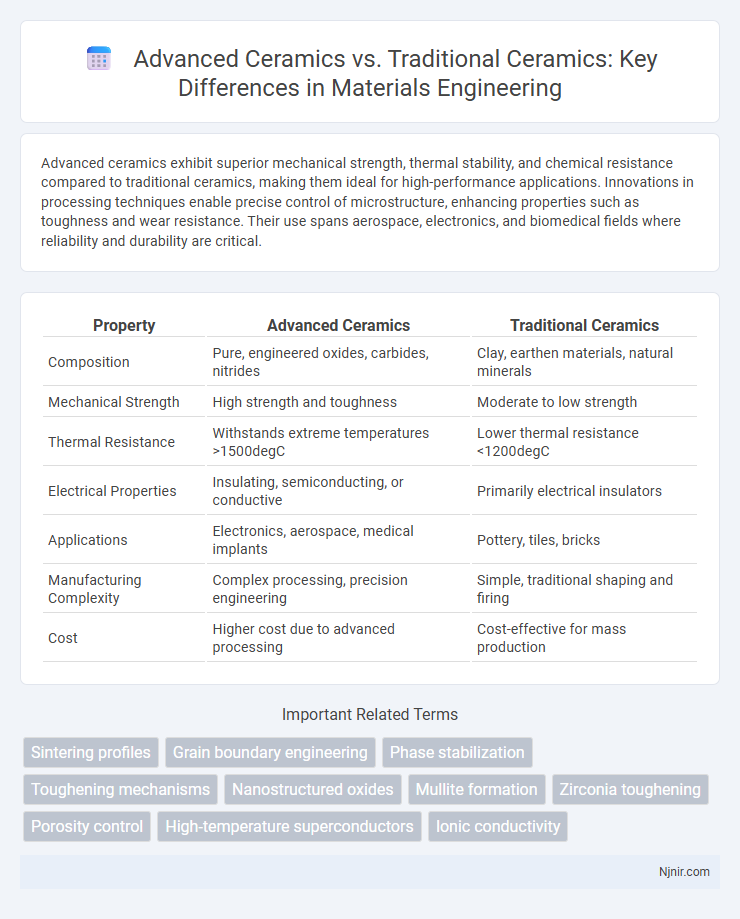

Table of Comparison

| Property | Advanced Ceramics | Traditional Ceramics |

|---|---|---|

| Composition | Pure, engineered oxides, carbides, nitrides | Clay, earthen materials, natural minerals |

| Mechanical Strength | High strength and toughness | Moderate to low strength |

| Thermal Resistance | Withstands extreme temperatures >1500degC | Lower thermal resistance <1200degC |

| Electrical Properties | Insulating, semiconducting, or conductive | Primarily electrical insulators |

| Applications | Electronics, aerospace, medical implants | Pottery, tiles, bricks |

| Manufacturing Complexity | Complex processing, precision engineering | Simple, traditional shaping and firing |

| Cost | Higher cost due to advanced processing | Cost-effective for mass production |

Overview of Ceramics: Definitions and Classifications

Ceramics encompass a broad class of inorganic, non-metallic materials typically classified into traditional and advanced types based on composition and performance characteristics. Traditional ceramics, including products like pottery and bricks, are primarily composed of natural clays and silica with a crystalline microstructure, optimized for basic structural applications. Advanced ceramics, or technical ceramics, consist of highly refined and engineered materials such as alumina, zirconia, and silicon carbide, designed for superior mechanical strength, thermal stability, and electrical properties in specialized industrial sectors.

Historical Development of Traditional Ceramics

Traditional ceramics have a history dating back thousands of years, with origins in ancient civilizations such as Mesopotamia and China, where they were primarily used for pottery, bricks, and tiles. These ceramics were typically made from natural clays and shaped by hand or simple tools before being fired in kilns to achieve hardness and durability. Over time, innovations like glazing and wheel-thrown techniques enhanced both the functional and aesthetic qualities of traditional ceramics, laying the foundation for modern ceramic technologies.

Emergence and Evolution of Advanced Ceramics

Advanced ceramics emerged in the mid-20th century as specialized materials engineered for superior mechanical, thermal, and electrical properties compared to traditional ceramics, which primarily consist of clay-based materials used for pottery and construction. The evolution of advanced ceramics involves the development of pure-phase materials like alumina, silicon carbide, and zirconia, designed for applications in aerospace, electronics, and medical implants. Innovations in processing techniques such as sintering, hot isostatic pressing, and additive manufacturing have enabled precise control over microstructure, enhancing durability, hardness, and resistance to wear and corrosion in advanced ceramic components.

Raw Materials and Processing Techniques

Advanced ceramics utilize high-purity raw materials such as alumina, silicon carbide, and zirconia, which require precise control to achieve superior mechanical and thermal properties. Traditional ceramics primarily rely on natural clays and silica with simpler processing techniques like shaping and firing at moderate temperatures. Advanced ceramics benefit from sophisticated manufacturing methods including powder processing, sintering at extreme temperatures, and hot isostatic pressing to enhance density and performance.

Microstructure and Phase Composition

Advanced ceramics exhibit a highly controlled microstructure characterized by fine, uniform grain sizes and minimal porosity, enhancing mechanical strength and thermal stability compared to traditional ceramics, which often have coarser grains and higher porosity. The phase composition of advanced ceramics typically consists of engineered phases such as alumina, zirconia, and silicon carbide optimized for specific properties, while traditional ceramics primarily contain natural clay minerals and quartz with less precise phase control. This refined microstructure and tailored phase composition in advanced ceramics result in superior wear resistance, strength, and chemical stability, making them suitable for high-performance applications.

Mechanical and Physical Properties Comparison

Advanced ceramics exhibit superior mechanical properties such as higher hardness, enhanced fracture toughness, and improved wear resistance compared to traditional ceramics, which are generally more brittle and less durable. Physically, advanced ceramics possess greater thermal stability, lower thermal expansion, and higher electrical insulation capabilities, enabling their use in high-performance applications like aerospace and electronics. Traditional ceramics, primarily composed of clay and silica, have limited mechanical strength and thermal resistance, restricting their application to structural and decorative purposes.

Performance in High-Temperature Applications

Advanced ceramics exhibit superior thermal stability and mechanical strength compared to traditional ceramics, making them ideal for high-temperature applications in aerospace and automotive industries. Their enhanced resistance to thermal shock, corrosion, and wear allows operation at temperatures exceeding 1,000degC, surpassing the limits of conventional ceramics. Advanced ceramic materials such as silicon carbide and alumina provide reliable performance in extreme environments where traditional ceramics would fail or degrade rapidly.

Electrical and Thermal Conductivity Differences

Advanced ceramics exhibit significantly lower electrical conductivity compared to traditional ceramics due to their highly controlled microstructures and pure compositions, making them ideal for insulating applications. They also demonstrate superior thermal conductivity properties, often engineered to enhance heat dissipation in electronic devices, unlike traditional ceramics which typically have lower thermal conductivity. These differences arise from advanced ceramics' refined grain sizes and specialized additives, optimizing their performance in high-tech industries such as aerospace and electronics.

Industrial and Technological Applications

Advanced ceramics exhibit superior mechanical strength, thermal stability, and electrical insulation compared to traditional ceramics, making them essential in industrial applications like aerospace components, electronic substrates, and cutting tools. Traditional ceramics primarily serve construction and household uses due to their lower strength and higher porosity. High-purity alumina, zirconia, and silicon carbide are key materials in advanced ceramics that enable innovations in semiconductor manufacturing, medical devices, and wear-resistant coatings.

Future Trends and Challenges in Ceramic Materials

Advanced ceramics are poised to dominate future markets due to their superior mechanical strength, thermal stability, and electrical properties compared to traditional ceramics. Innovations in nanotechnology and additive manufacturing are driving enhanced performance and new applications in aerospace, electronics, and biomedical industries. Key challenges include improving cost-efficiency, scalability, and environmental sustainability during production to meet increasing demand for high-performance ceramic materials.

Sintering profiles

Advanced ceramics use precise sintering profiles with controlled heating rates, dwell times, and atmospheres to achieve superior density and mechanical properties compared to the less controlled sintering processes of traditional ceramics.

Grain boundary engineering

Grain boundary engineering in advanced ceramics enhances mechanical strength, electrical conductivity, and thermal stability compared to traditional ceramics by optimizing grain boundary structure and chemistry.

Phase stabilization

Phase stabilization in advanced ceramics is achieved through precise control of dopants and microstructure, enhancing mechanical properties and thermal stability compared to traditional ceramics.

Toughening mechanisms

Advanced ceramics utilize toughening mechanisms such as transformation toughening, microcrack toughening, and fiber reinforcement, significantly enhancing fracture resistance compared to traditional ceramics, which primarily rely on inherent material brittleness and limited crack deflection.

Nanostructured oxides

Nanostructured oxides in advanced ceramics exhibit superior mechanical strength, thermal stability, and electrical properties compared to traditional ceramics due to their controlled nanoscale grain size and enhanced interface characteristics.

Mullite formation

Advanced ceramics exhibit enhanced mullite formation characterized by higher purity and controlled microstructure compared to traditional ceramics, resulting in superior thermal stability and mechanical strength.

Zirconia toughening

Zirconia toughening in advanced ceramics significantly enhances fracture toughness and mechanical strength compared to traditional ceramics.

Porosity control

Advanced ceramics achieve superior porosity control through precise microstructural engineering, resulting in enhanced mechanical strength and thermal stability compared to traditional ceramics with higher and less controlled porosity levels.

High-temperature superconductors

High-temperature superconductors, a crucial subset of advanced ceramics, exhibit superior electrical conductivity and thermal stability compared to traditional ceramics, enabling their use in cutting-edge energy and electronic applications.

Ionic conductivity

Advanced ceramics exhibit significantly higher ionic conductivity than traditional ceramics due to their tailored crystalline structures and enhanced defect chemistry.

advanced ceramics vs traditional ceramics Infographic

njnir.com

njnir.com