Biodegradable polymers offer a sustainable alternative to conventional plastics by breaking down naturally through microbial activity, reducing environmental pollution and landfill accumulation. These polymers are typically derived from renewable resources, enhancing their eco-friendly profile compared to petroleum-based plastics that persist for centuries. Innovations in materials engineering aim to improve the mechanical properties and degradation rates of biodegradable polymers to match the durability and versatility of conventional plastics.

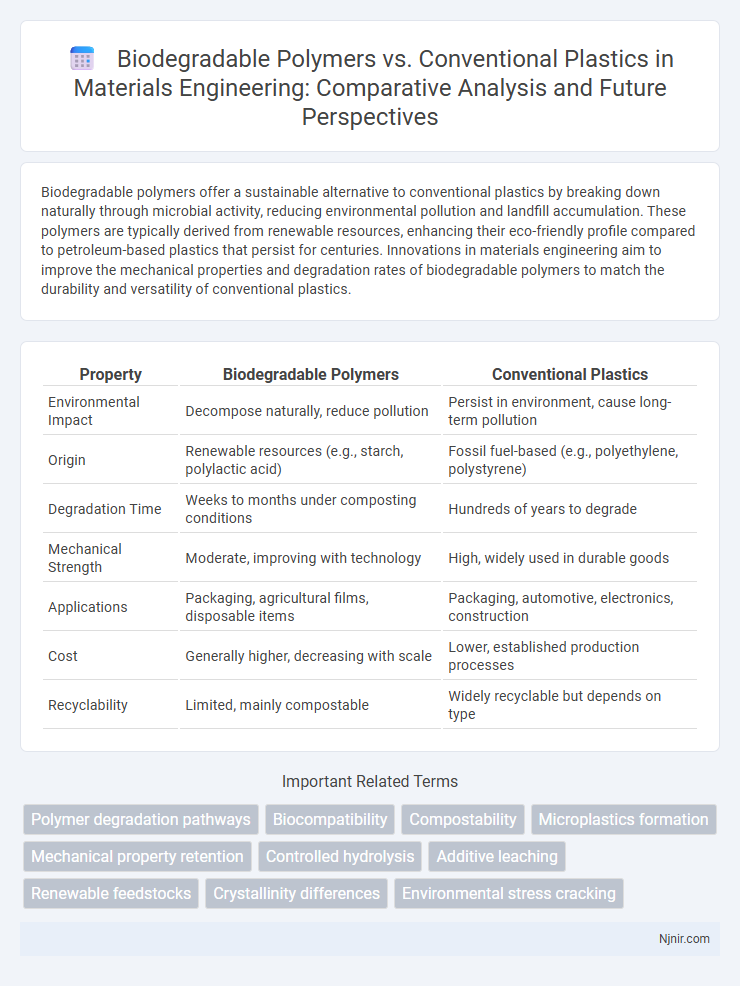

Table of Comparison

| Property | Biodegradable Polymers | Conventional Plastics |

|---|---|---|

| Environmental Impact | Decompose naturally, reduce pollution | Persist in environment, cause long-term pollution |

| Origin | Renewable resources (e.g., starch, polylactic acid) | Fossil fuel-based (e.g., polyethylene, polystyrene) |

| Degradation Time | Weeks to months under composting conditions | Hundreds of years to degrade |

| Mechanical Strength | Moderate, improving with technology | High, widely used in durable goods |

| Applications | Packaging, agricultural films, disposable items | Packaging, automotive, electronics, construction |

| Cost | Generally higher, decreasing with scale | Lower, established production processes |

| Recyclability | Limited, mainly compostable | Widely recyclable but depends on type |

Introduction to Biodegradable Polymers and Conventional Plastics

Biodegradable polymers are materials designed to decompose naturally through microbial activity, reducing environmental impact and waste accumulation. Conventional plastics, derived primarily from petrochemicals, resist degradation and contribute significantly to pollution and landfill overflow. The shift towards biodegradable polymers aims to address the sustainability challenges posed by the persistent nature of traditional plastics.

Chemical Structure and Composition Differences

Biodegradable polymers are composed of natural or synthetic monomers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) that contain hydrolysable ester bonds, enabling microbial degradation through enzymatic hydrolysis. Conventional plastics, such as polyethylene (PE) and polypropylene (PP), consist of long hydrocarbon chains with C-C and C-H bonds, making them chemically inert and resistant to microbial attack. The presence of functional groups like esters in biodegradable polymers contrasts with the non-polar hydrocarbon backbone of conventional plastics, directly influencing their environmental degradation pathways and lifespans.

Environmental Impact Assessment

Biodegradable polymers significantly reduce environmental impact by breaking down into non-toxic substances within months, minimizing long-term pollution compared to conventional plastics, which can persist for centuries and accumulate in ecosystems. Environmental Impact Assessment studies reveal that biodegradable polymers contribute to lower greenhouse gas emissions, reduced landfill volume, and decreased microplastic contamination in marine and terrestrial habitats. However, factors such as production energy, raw material sourcing, and degradation conditions must be considered to fully evaluate their sustainability benefits over traditional petrochemical-based plastics.

Degradation Mechanisms and Lifespan

Biodegradable polymers degrade through microbial action, enzymatic breakdown, and hydrolysis, resulting in shorter environmental persistence ranging from weeks to months depending on conditions. Conventional plastics primarily undergo photodegradation and thermal oxidation, leading to fragmentation but not complete mineralization, which extends their lifespan to decades or even centuries in landfills and oceans. The faster degradation mechanisms of biodegradable polymers make them preferable for reducing plastic pollution and minimizing long-term ecological impact.

Mechanical and Physical Properties Comparison

Biodegradable polymers generally exhibit lower tensile strength and reduced thermal stability compared to conventional plastics, limiting their use in high-stress applications. Conventional plastics like polyethylene and polypropylene show superior durability, higher melting points, and better resistance to environmental factors. The elastic modulus of biodegradable polymers is often lower, resulting in more flexibility but less rigidity, which affects their mechanical performance in packaging and structural components.

Processing and Manufacturing Techniques

Biodegradable polymers are processed using techniques such as injection molding, extrusion, and blow molding, similar to conventional plastics but often require lower processing temperatures to prevent thermal degradation. Their manufacturing demands careful control of moisture and temperature to maintain polymer integrity and optimize biodegradability, contrasting with conventional plastics that tolerate broader processing conditions due to their synthetic stability. Advances in reactive extrusion and solvent casting enhance the production efficiency of biodegradable polymers, while conventional plastics benefit from well-established large-scale manufacturing infrastructure.

Applications in Packaging and Consumer Products

Biodegradable polymers, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), offer sustainable alternatives to conventional plastics like polyethylene (PE) and polypropylene (PP) in packaging and consumer products by reducing environmental impact through compostability and reduced microplastic pollution. These polymers are increasingly used in food packaging, disposable cutlery, and shopping bags, providing functional properties comparable to their petroleum-based counterparts while supporting circular economy principles. Conventional plastics dominate due to cost-effectiveness and durability but contribute significantly to plastic waste accumulation and long-term pollution challenges.

Regulatory Standards and Certifications

Biodegradable polymers undergo stringent regulatory standards such as ASTM D6400 and EN 13432, ensuring their compostability and environmental safety, unlike many conventional plastics which often lack comprehensive biodegradability certifications. Certifications from organizations like the Biodegradable Products Institute (BPI) and TUV Austria serve as crucial benchmarks for verifying compliance with global compostability and biodegradability requirements. Regulatory frameworks in the EU, US, and other regions increasingly mandate proper labeling and certification to promote the adoption of eco-friendly biodegradable alternatives over traditional plastics.

Economic Feasibility and Market Trends

Biodegradable polymers are gaining market share due to increasing consumer demand for sustainable alternatives, yet they often face higher production costs compared to conventional plastics derived from petrochemicals. Economic feasibility improves with advancements in biopolymer technology and scaling of production facilities, driving prices closer to those of traditional plastics. Market trends indicate a steady rise in investments and regulatory support favoring biodegradable materials, particularly in packaging and agriculture sectors.

Future Prospects and Innovations in Sustainable Materials

Biodegradable polymers hold significant promise over conventional plastics due to their ability to decompose naturally, reducing long-term environmental pollution and dependency on fossil fuels. Innovations in sustainable materials focus on enhancing the mechanical properties and cost-effectiveness of biodegradable polymers, enabling wider application in packaging, agriculture, and biomedical fields. Advances in bio-based composites, enzymatic degradation processes, and nanotechnology integration are driving the next generation of eco-friendly alternatives that combine performance with environmental responsibility.

Polymer degradation pathways

Biodegradable polymers degrade primarily through enzymatic hydrolysis and microbial assimilation, contrasting with conventional plastics that persist due to their resistance to microbial and environmental breakdown pathways.

Biocompatibility

Biodegradable polymers exhibit superior biocompatibility compared to conventional plastics, making them ideal for medical applications and reducing toxic responses in biological environments.

Compostability

Biodegradable polymers offer superior compostability compared to conventional plastics by breaking down faster and producing less environmental waste.

Microplastics formation

Biodegradable polymers significantly reduce microplastic formation compared to conventional plastics by breaking down more completely in natural environments.

Mechanical property retention

Biodegradable polymers exhibit lower mechanical property retention compared to conventional plastics, which maintain superior strength and durability over extended usage and environmental exposure.

Controlled hydrolysis

Controlled hydrolysis in biodegradable polymers enables precise degradation rates, contrasting with conventional plastics that resist breakdown and contribute to long-term environmental pollution.

Additive leaching

Biodegradable polymers significantly reduce additive leaching compared to conventional plastics, minimizing environmental toxicity and improving soil and water quality.

Renewable feedstocks

Biodegradable polymers derived from renewable feedstocks reduce environmental impact compared to conventional plastics primarily made from non-renewable fossil fuels.

Crystallinity differences

Biodegradable polymers generally exhibit lower crystallinity than conventional plastics, resulting in faster degradation rates and altered mechanical properties.

Environmental stress cracking

Biodegradable polymers exhibit significantly lower environmental stress cracking resistance compared to conventional plastics, reducing long-term pollution risks.

Biodegradable polymers vs Conventional plastics Infographic

njnir.com

njnir.com