Bio-based epoxy resins offer sustainable alternatives to petroleum-based epoxies by utilizing renewable resources such as plant oils and natural fibers, reducing environmental impact. These bio-based epoxies exhibit comparable mechanical strength, chemical resistance, and thermal stability, making them suitable for various industrial applications. Advances in bio-based formulations enhance biodegradability and lower carbon footprint while maintaining performance standards traditionally achieved by petroleum-based epoxy systems.

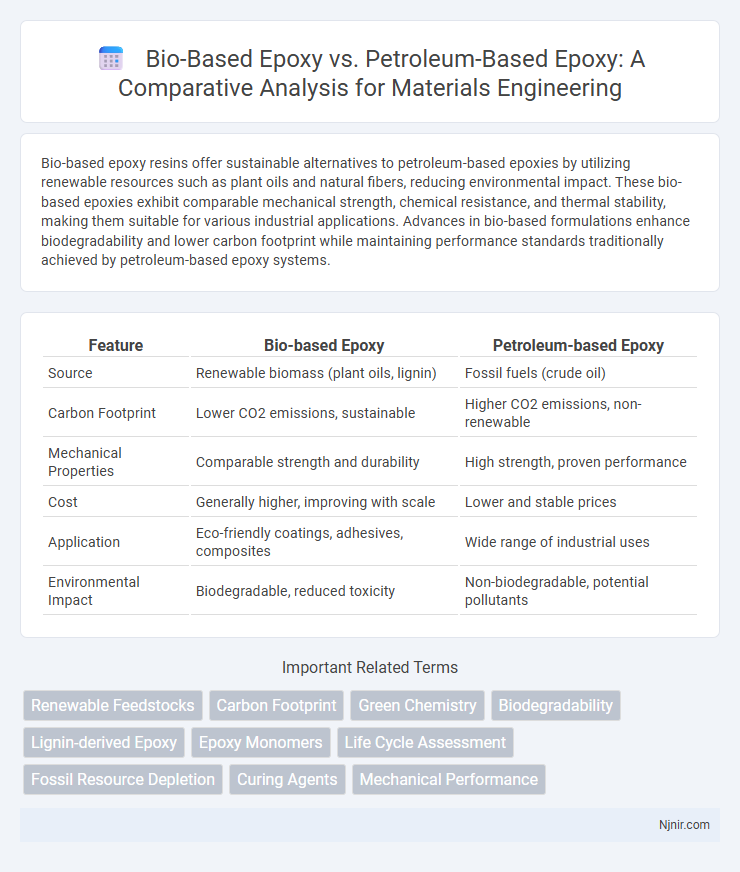

Table of Comparison

| Feature | Bio-based Epoxy | Petroleum-based Epoxy |

|---|---|---|

| Source | Renewable biomass (plant oils, lignin) | Fossil fuels (crude oil) |

| Carbon Footprint | Lower CO2 emissions, sustainable | Higher CO2 emissions, non-renewable |

| Mechanical Properties | Comparable strength and durability | High strength, proven performance |

| Cost | Generally higher, improving with scale | Lower and stable prices |

| Application | Eco-friendly coatings, adhesives, composites | Wide range of industrial uses |

| Environmental Impact | Biodegradable, reduced toxicity | Non-biodegradable, potential pollutants |

Introduction to Epoxy Resins in Materials Engineering

Epoxy resins in materials engineering are critical polymers known for their strong adhesion, chemical resistance, and mechanical properties, widely used in coatings, composites, and adhesives. Bio-based epoxy resins, derived from renewable raw materials like plant oils and lignin, offer sustainable alternatives with reduced environmental impact compared to traditional petroleum-based epoxy resins synthesized from fossil fuels. The shift toward bio-based epoxies addresses increasing demand for eco-friendly materials while maintaining performance standards essential for advanced engineering applications.

Chemical Structure: Bio-based vs Petroleum-based Epoxy

Bio-based epoxy resins consist primarily of renewable organic compounds such as plant oils and lignin derivatives, featuring aliphatic and aromatic structures that introduce functional hydroxyl groups enhancing biodegradability. Petroleum-based epoxies are derived from petrochemical feedstocks like bisphenol-A, characterized by rigid aromatic rings and epoxy groups contributing to high thermal stability and mechanical strength. The chemical structure differences influence the resin's environmental impact, reactivity, and application performance, with bio-based epoxies offering sustainable alternatives through renewable molecular frameworks.

Sourcing of Raw Materials

Bio-based epoxy resins are derived primarily from renewable resources such as plant oils, lignin, and other biomass, reducing reliance on fossil fuels and lowering carbon footprints. Petroleum-based epoxies depend on non-renewable crude oil extraction, contributing to finite resource depletion and environmental concerns. The sustainable sourcing of raw materials for bio-based epoxy supports circular economy principles and enhances material lifecycle benefits.

Synthesis and Manufacturing Processes

Bio-based epoxy is synthesized primarily from renewable resources such as plant oils, lignin, or carbohydrates, utilizing green chemistry approaches that emphasize reduced environmental impact and lower carbon footprint during manufacturing. Petroleum-based epoxy production involves petrochemical feedstocks like bisphenol-A and epichlorohydrin, relying on energy-intensive processes and non-renewable fossil fuels. Advances in bio-catalysts and fermentation technologies are enhancing the scalability and cost-efficiency of bio-based epoxy synthesis, presenting a sustainable alternative to conventional petroleum-based epoxies.

Mechanical and Thermal Properties Comparison

Bio-based epoxy exhibits comparable mechanical strength and enhanced thermal stability relative to petroleum-based epoxy, making it suitable for sustainable applications. The tensile strength of bio-based epoxy typically ranges from 40 to 70 MPa, closely matching petroleum-based counterparts while displaying higher glass transition temperatures (Tg) up to 150degC. Improved thermal resistance and lower carbon footprint position bio-based epoxy as a promising alternative in high-performance composites and coatings.

Environmental Impact and Sustainability

Bio-based epoxy resins significantly reduce carbon footprint by utilizing renewable resources like plant oils and lignin, which leads to lower greenhouse gas emissions compared to conventional petroleum-based epoxies. The biodegradability and reduced toxicity of bio-based epoxies contribute to enhanced environmental safety, minimizing ecological damage during production, usage, and disposal. In contrast, petroleum-based epoxies rely on finite fossil fuels, generating substantial environmental pollution and posing challenges to sustainability due to resource depletion and higher energy consumption.

Performance in Industrial Applications

Bio-based epoxy resins exhibit comparable mechanical strength, chemical resistance, and thermal stability to petroleum-based epoxy, making them suitable for demanding industrial applications such as coatings, adhesives, and composite materials. Enhanced sustainability and reduced environmental impact drive their adoption without compromising performance benchmarks like tensile strength and curing time. Industrial sectors increasingly prefer bio-based epoxy for achieving durability, corrosion resistance, and strong adhesion in automotive, aerospace, and electronics manufacturing.

Cost and Market Availability

Bio-based epoxy resins typically have higher production costs due to the limited scalability and raw material expenses compared to petroleum-based epoxy, which benefits from established supply chains and economies of scale. Market availability of petroleum-based epoxy dominates with widespread commercial production and extensive industrial applications, while bio-based epoxy remains niche, primarily targeting eco-conscious segments and specialty markets. Price sensitivity in large-scale construction and manufacturing favors petroleum-based options despite growing environmental regulations driving incremental demand for bio-based alternatives.

Lifecycle Analysis and End-of-Life Options

Bio-based epoxy resins typically demonstrate lower carbon footprints during lifecycle analysis compared to petroleum-based epoxies, due to renewable raw materials and reduced greenhouse gas emissions during production. End-of-life options for bio-based epoxies include enhanced biodegradability or recyclability, improving waste management sustainability, whereas petroleum-based epoxies often require energy-intensive incineration or landfill disposal. Lifecycle assessments emphasize the environmental benefits of bio-based epoxy through reduced fossil fuel dependency and improved end-of-life degradation potential.

Future Trends and Research Directions

Future trends in bio-based epoxy focus on enhancing mechanical properties and thermal stability to match petroleum-based counterparts, driven by sustainability and environmental regulations. Research directions prioritize the development of novel bio-derived monomers and green curing agents to reduce carbon footprint while maintaining performance. Emerging studies explore hybrid formulations combining bio-based and petroleum-based components to optimize cost-effectiveness and functional versatility in industrial applications.

Renewable Feedstocks

Bio-based epoxy resins utilize renewable feedstocks derived from plant oils and biomass, significantly reducing reliance on finite petroleum resources compared to traditional petroleum-based epoxy resins.

Carbon Footprint

Bio-based epoxy reduces carbon footprint by utilizing renewable resources and lowering greenhouse gas emissions compared to petroleum-based epoxy derived from fossil fuels.

Green Chemistry

Bio-based epoxy resins derived from renewable biomass offer eco-friendly alternatives to petroleum-based epoxies by reducing carbon footprint and enhancing sustainability in green chemistry applications.

Biodegradability

Bio-based epoxy exhibits significantly higher biodegradability compared to petroleum-based epoxy, making it an environmentally sustainable alternative in polymer applications.

Lignin-derived Epoxy

Lignin-derived bio-based epoxy offers enhanced sustainability, reduced carbon footprint, and comparable mechanical properties compared to traditional petroleum-based epoxy resins.

Epoxy Monomers

Bio-based epoxy monomers derived from renewable resources offer lower environmental impact and enhanced sustainability compared to traditional petroleum-based epoxy monomers, which rely on fossil fuels and contribute to higher carbon emissions.

Life Cycle Assessment

Bio-based epoxy resins exhibit a lower carbon footprint and reduced environmental impact in Life Cycle Assessment compared to petroleum-based epoxy due to renewable raw materials and improved biodegradability.

Fossil Resource Depletion

Bio-based epoxy significantly reduces fossil resource depletion by utilizing renewable biomass, unlike petroleum-based epoxy which relies heavily on finite fossil fuels.

Curing Agents

Bio-based epoxy curing agents derived from renewable resources offer lower toxicity and improved environmental sustainability compared to traditional petroleum-based epoxy curing agents, which are often associated with higher VOC emissions and greater ecological impact.

Mechanical Performance

Bio-based epoxy demonstrates comparable or superior mechanical performance to petroleum-based epoxy, offering enhanced tensile strength, flexibility, and impact resistance while reducing environmental impact.

Bio-based Epoxy vs Petroleum-based Epoxy Infographic

njnir.com

njnir.com