Thermoset polymers form irreversible chemical bonds during curing, resulting in rigid, heat-resistant materials ideal for high-strength structural applications. Thermoplastics consist of linear or branched polymers that soften when heated and harden upon cooling, allowing for easy reshaping and recyclability. The choice between thermoset and thermoplastic materials depends on factors like mechanical performance, thermal stability, and manufacturing processes.

Table of Comparison

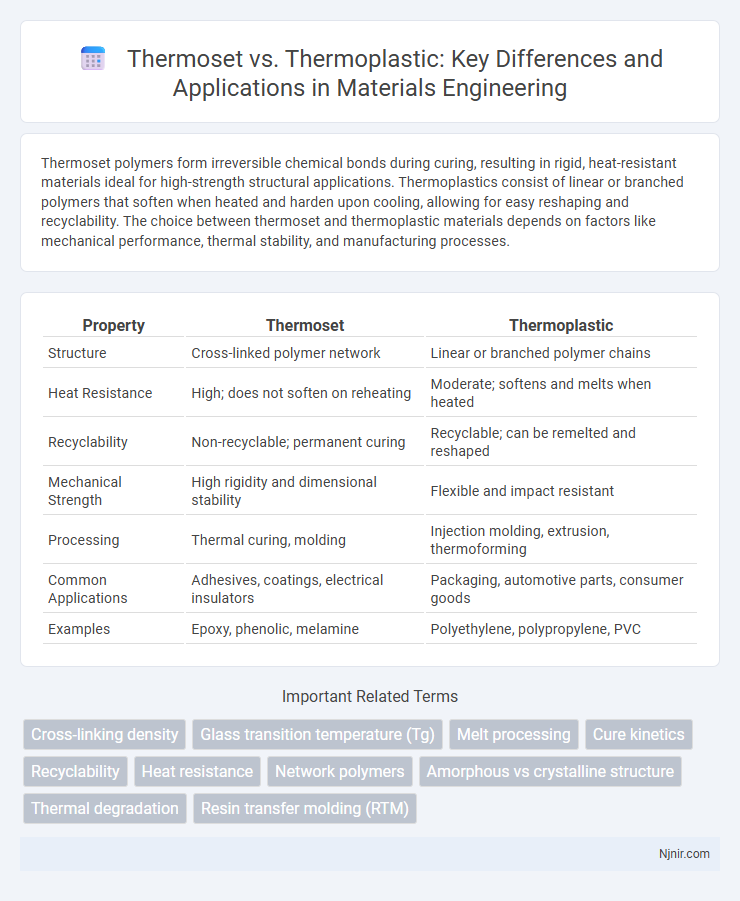

| Property | Thermoset | Thermoplastic |

|---|---|---|

| Structure | Cross-linked polymer network | Linear or branched polymer chains |

| Heat Resistance | High; does not soften on reheating | Moderate; softens and melts when heated |

| Recyclability | Non-recyclable; permanent curing | Recyclable; can be remelted and reshaped |

| Mechanical Strength | High rigidity and dimensional stability | Flexible and impact resistant |

| Processing | Thermal curing, molding | Injection molding, extrusion, thermoforming |

| Common Applications | Adhesives, coatings, electrical insulators | Packaging, automotive parts, consumer goods |

| Examples | Epoxy, phenolic, melamine | Polyethylene, polypropylene, PVC |

Introduction to Thermosets and Thermoplastics

Thermosets are polymers that undergo a chemical curing process, creating a rigid, three-dimensional network that cannot be remelted or reshaped, making them ideal for high-heat and structural applications. Thermoplastics consist of long polymer chains that soften when heated and harden upon cooling, allowing repeated shaping and recycling, which benefits manufacturing versatility and sustainability. Key thermoset materials include epoxy and phenolic resins, while common thermoplastics cover polyethylene, polypropylene, and polycarbonate.

Fundamental Chemical Structures

Thermosets possess a highly cross-linked, three-dimensional polymer network that provides exceptional thermal stability and rigidity, preventing them from melting upon reheating. Thermoplastics feature linear or branched polymer chains without extensive cross-linking, allowing them to soften and reshape when heated multiple times. The irreversible curing reaction in thermosets contrasts with the reversible melting process in thermoplastics, defining their fundamental chemical behavior and applications.

Manufacturing and Processing Methods

Thermoset plastics undergo irreversible curing through chemical reactions involving heat or catalysts, resulting in a rigid, cross-linked molecular structure that cannot be remelted or reshaped, making manufacturing processes like injection molding, compression molding, and transfer molding suitable. Thermoplastics, composed of linear or branched polymers, soften upon heating and harden when cooled, allowing repeated melting and reshaping, which enables manufacturing techniques such as extrusion, injection molding, blow molding, and thermoforming. Processing thermosets requires precise control of curing times and temperatures to achieve desired mechanical properties, whereas thermoplastics offer faster cycle times and recyclability due to their reversible thermal behavior.

Mechanical and Thermal Properties

Thermoset polymers exhibit superior mechanical strength and thermal stability due to their cross-linked molecular structure, making them resistant to deformation under high temperatures. Thermoplastics possess lower mechanical rigidity but offer excellent impact resistance and can be remelted, allowing for easier recycling and reshaping. The thermal degradation temperature of thermosets typically exceeds 200degC, while thermoplastics generally have melting points below 250degC, influencing their application in high-performance environments.

Applications in Industry

Thermosets are widely used in electrical insulation, automotive components, and aerospace parts due to their high heat resistance and structural rigidity. Thermoplastics find extensive applications in packaging, consumer goods, and medical devices because of their recyclability and ease of molding. The choice between thermoset and thermoplastic materials depends on requirements for durability, thermal stability, and manufacturing flexibility in industrial production.

Recyclability and Environmental Impact

Thermoset plastics, being cross-linked, are generally non-recyclable through conventional methods, leading to longer landfill retention and higher environmental impact due to their resistance to degradation. Thermoplastics can be melted and reshaped multiple times, enabling efficient recycling processes that reduce waste and conserve resources. Choosing thermoplastics over thermosets significantly lowers carbon footprint and supports sustainable material management in industries like automotive and packaging.

Cost and Economic Considerations

Thermoplastics generally offer lower production costs due to faster processing cycles and easier recyclability, reducing waste and material expenses. Thermosets often require higher initial investment in molding and curing equipment, along with longer cycle times that increase labor and energy costs. Despite higher upfront costs, thermosets provide superior mechanical properties and thermal stability, which can yield long-term economic benefits in high-performance applications.

Performance Under Stress and Aging

Thermosets maintain superior mechanical strength and dimensional stability under prolonged stress and aging due to their cross-linked polymer structure, preventing deformation and degradation. Thermoplastics exhibit increased susceptibility to creep, stress relaxation, and chemical breakdown over time when exposed to high temperatures or mechanical loads because of their linear or branched molecular chains. The inherent irreversible curing process in thermosets enhances their resistance to thermal and chemical aging compared to the reversible softening mechanisms in thermoplastics.

Innovations and Emerging Trends

Innovations in thermoset materials include the development of bio-based resins and advanced curing technologies that enhance durability and reduce environmental impact. Thermoplastics are witnessing breakthroughs in recycled polymers and additive manufacturing compatibility, driving lightweight and customizable applications. Emerging trends highlight the convergence of hybrid materials combining thermoset toughness with thermoplastic recyclability for superior performance across automotive and aerospace industries.

Choosing the Right Material for Your Application

Selecting between thermoset and thermoplastic materials depends on the application's mechanical strength, heat resistance, and durability requirements. Thermosets offer superior chemical resistance and structural integrity at high temperatures, ideal for automotive and aerospace components. Thermoplastics provide greater flexibility, recyclability, and ease of molding, making them suitable for consumer products and packaging.

Cross-linking density

Thermosets exhibit high cross-linking density creating rigid, heat-resistant structures, while thermoplastics have low or no cross-linking, allowing them to be melted and reshaped.

Glass transition temperature (Tg)

Thermosets generally exhibit higher glass transition temperatures (Tg) compared to thermoplastics due to their crosslinked molecular structures that restrict polymer chain mobility.

Melt processing

Thermoplastics undergo reversible melt processing that allows reshaping by heating, whereas thermosets chemically cure into a rigid structure that cannot be remelted or reshaped after initial processing.

Cure kinetics

Cure kinetics of thermosets involve irreversible cross-linking reactions that solidify the polymer matrix under heat or catalysts, whereas thermoplastics do not undergo curing but instead soften upon heating due to physical phase changes.

Recyclability

Thermoplastics offer superior recyclability compared to thermosets due to their ability to be repeatedly melted and reshaped without significant degradation.

Heat resistance

Thermosets exhibit superior heat resistance due to their cross-linked molecular structure, which prevents melting, unlike thermoplastics that soften and deform at high temperatures.

Network polymers

Thermoset polymers form irreversible cross-linked network structures that provide superior heat resistance and mechanical strength compared to the non-cross-linked, re-moldable chains of thermoplastic polymers.

Amorphous vs crystalline structure

Thermosets typically exhibit an amorphous structure due to their crosslinked polymer chains, while thermoplastics can have either amorphous or crystalline structures, with crystalline thermoplastics offering higher density and mechanical strength.

Thermal degradation

Thermosets resist thermal degradation by forming rigid, cross-linked networks that maintain structural integrity at high temperatures, whereas thermoplastics soften and degrade more readily due to their linear or branched polymer chains.

Resin transfer molding (RTM)

Thermoset resins used in Resin Transfer Molding (RTM) provide superior heat resistance and mechanical strength compared to thermoplastic resins, which offer faster processing times and recyclability in composite manufacturing.

thermoset vs thermoplastic Infographic

njnir.com

njnir.com