3D printing metals offers superior mechanical strength, thermal resistance, and durability compared to polymers, making it ideal for aerospace, automotive, and medical applications where performance under stress is critical. Metal additive manufacturing allows for complex geometries and internal structures unattainable through traditional methods, while polymers provide faster production, lower costs, and enhanced flexibility for prototyping and low-load applications. Optimizing material choice depends on balancing the required mechanical properties with manufacturing speed and cost-effectiveness in materials engineering projects.

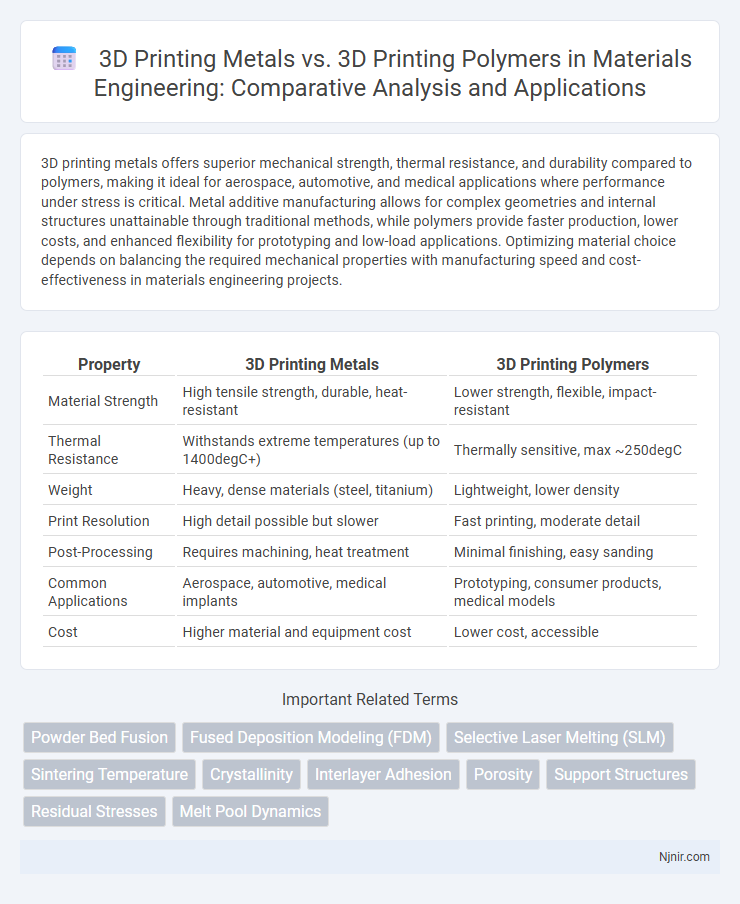

Table of Comparison

| Property | 3D Printing Metals | 3D Printing Polymers |

|---|---|---|

| Material Strength | High tensile strength, durable, heat-resistant | Lower strength, flexible, impact-resistant |

| Thermal Resistance | Withstands extreme temperatures (up to 1400degC+) | Thermally sensitive, max ~250degC |

| Weight | Heavy, dense materials (steel, titanium) | Lightweight, lower density |

| Print Resolution | High detail possible but slower | Fast printing, moderate detail |

| Post-Processing | Requires machining, heat treatment | Minimal finishing, easy sanding |

| Common Applications | Aerospace, automotive, medical implants | Prototyping, consumer products, medical models |

| Cost | Higher material and equipment cost | Lower cost, accessible |

Introduction to 3D Printing Metals and Polymers

3D printing metals involves additive manufacturing techniques like selective laser melting (SLM) and electron beam melting (EBM), which enable the creation of complex, high-strength metal parts used in aerospace and medical implants. In contrast, 3D printing polymers primarily employs fused deposition modeling (FDM) and stereolithography (SLA), producing lightweight, flexible components ideal for prototyping, consumer products, and custom tooling. Metal 3D printing requires higher processing temperatures and advanced machinery, while polymer printing offers greater accessibility and cost-effectiveness for diverse applications.

Material Properties: Metals vs Polymers

3D printing metals offers superior mechanical strength, thermal resistance, and durability compared to polymers, making them ideal for aerospace, automotive, and medical implants. Polymers provide greater flexibility, lighter weight, and ease of processing, suitable for prototyping, consumer products, and complex geometries with lower cost. Metal materials like titanium, stainless steel, and aluminum exhibit enhanced wear resistance and conductivity, whereas polymers such as ABS, PLA, and Nylon prioritize impact resistance and chemical stability.

Process Technologies: Metal vs Polymer Printing Methods

Metal 3D printing primarily utilizes processes like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), which involve high-energy beams to fuse metal powders layer by layer, resulting in dense, strong parts suitable for aerospace and automotive industries. Polymer 3D printing commonly employs Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), using thermoplastics or photopolymeric resins that offer versatility and faster prototyping but typically lower mechanical strength. Metal additive manufacturing requires controlled atmospheres and higher energy input, whereas polymer methods operate at lower temperatures with broader material flexibility, influencing the choice based on application requirements.

Mechanical Performance Comparison

3D printing metals offers superior mechanical performance compared to polymers, with metals providing higher tensile strength, stiffness, and heat resistance essential for aerospace and automotive applications. Polymers, while more flexible and lightweight, generally exhibit lower impact resistance and durability under high-stress conditions. The choice between metal and polymer 3D printing depends on the mechanical requirements of the end-use part, such as load-bearing capacity and environmental exposure.

Applications in Industry: Metals and Polymers

3D printing metals is extensively used in aerospace, automotive, and medical industries for producing high-strength, heat-resistant components such as engine parts, implants, and custom prosthetics. Polymer 3D printing dominates in prototyping, consumer products, and lightweight components manufacturing, offering flexibility, rapid production, and cost efficiency. Metals provide durability and structural integrity critical for load-bearing applications, while polymers enable intricate design complexity and rapid iteration in less demanding mechanical environments.

Surface Finish and Post-Processing Requirements

3D printing metals typically produces parts with a rougher surface finish due to powder-based processes like DMLS and SLM, requiring extensive post-processing such as machining, polishing, and heat treatments to achieve functional and aesthetic standards. In contrast, 3D printing polymers, especially using methods like SLA and PolyJet, yields smoother surface finishes directly from the printer, significantly reducing the need for post-processing steps. The differing material properties and printing technologies dictate that metal parts often demand more time-intensive finishing to meet industry tolerances compared to polymer parts.

Cost Analysis: Metal vs Polymer 3D Printing

Metal 3D printing generally incurs higher costs due to expensive raw materials like titanium and stainless steel powders, as well as increased energy consumption and longer processing times compared to polymers such as PLA and ABS. Polymer 3D printing offers cost advantages with lower material prices and faster production rates, making it ideal for prototyping and low-volume manufacturing. However, the durability and mechanical properties of metal parts often justify the elevated expenses in aerospace, automotive, and medical applications where performance and strength are critical.

Design Flexibility and Limitations

Metal 3D printing offers superior strength and thermal resistance, enabling complex geometries for aerospace and automotive parts, but is limited by slower print speeds and higher costs. Polymer 3D printing provides greater design flexibility with faster production times and a wide variety of colors and finishes, though it generally lacks the durability and heat resistance of metals. Both technologies continue to evolve, with metal printing improving in surface finish and polymer methods advancing in mechanical properties.

Environmental Impact and Sustainability

3D printing metals typically involves higher energy consumption and greater carbon emissions compared to polymers due to intensive melting and post-processing requirements. Polymers, especially biodegradable or recycled types, offer lower environmental impact and improved sustainability through reduced waste and less energy-intensive production. However, advancements in metal powder recycling and energy-efficient metal printing technologies are gradually narrowing the sustainability gap between the two materials.

Future Trends and Innovations in Metal and Polymer 3D Printing

Future trends in 3D printing emphasize increased precision and material diversity for metals, with innovations like multi-material printing and advanced alloy development enhancing aerospace and medical applications. Polymer 3D printing advances include biodegradable materials, improved mechanical properties, and faster printing technologies, targeting automotive and consumer goods industries. Integration of AI-driven design and real-time monitoring in both metal and polymer 3D printing promises optimized production processes and customized manufacturing outcomes.

Powder Bed Fusion

Powder Bed Fusion in 3D printing enables high-precision metal parts with superior mechanical properties compared to polymers, which offer greater flexibility and lower material costs but lower thermal resistance and structural strength.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) 3D printing of metals involves high-temperature extrusion and post-processing sintering for strength, while polymer FDM offers lower-cost, versatile, and easier-to-use printing with limited mechanical properties.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) enables the production of intricate metal parts with superior mechanical properties and density compared to polymers used in 3D printing, which generally offer lower strength and thermal resistance but greater design flexibility and cost-effectiveness.

Sintering Temperature

3D printing metals requires significantly higher sintering temperatures, often above 1,200degC, compared to polymers that typically sinter below 300degC, impacting material properties and energy consumption.

Crystallinity

3D printing metals typically exhibit higher crystallinity with ordered grain structures, enhancing mechanical strength and thermal resistance, whereas 3D printing polymers often result in amorphous or semi-crystalline phases influencing flexibility and impact resistance.

Interlayer Adhesion

3D printing metals exhibit superior interlayer adhesion due to metallurgical bonding, whereas 3D printing polymers often face weaker adhesion caused by limited polymer chain entanglement and thermal diffusion.

Porosity

Metal 3D printing typically results in lower porosity and higher structural density compared to polymer 3D printing, which often exhibits increased porosity affecting mechanical strength and durability.

Support Structures

Metal 3D printing typically requires more complex and robust support structures due to higher melting temperatures and thermal stresses, whereas polymer 3D printing utilizes simpler, easily removable supports because of lower processing temperatures and material flexibility.

Residual Stresses

Residual stresses in 3D printing metals are significantly higher than in polymers due to rapid thermal gradients and phase transformations during metal solidification.

Melt Pool Dynamics

Melt pool dynamics in 3D printing metals involve higher temperatures and complex fluid flow compared to polymers, resulting in distinct microstructural properties and mechanical performance.

3D printing metals vs 3D printing polymers Infographic

njnir.com

njnir.com