Metal Matrix Composites (MMCs) offer superior toughness and thermal conductivity compared to Ceramic Matrix Composites (CMCs), making them ideal for applications requiring high impact resistance and efficient heat dissipation. Ceramic Matrix Composites excel in high-temperature stability and corrosion resistance, suited for extreme environments such as turbine engines and aerospace components. The choice between MMCs and CMCs depends on balancing mechanical performance with thermal and chemical durability tailored to specific engineering demands.

Table of Comparison

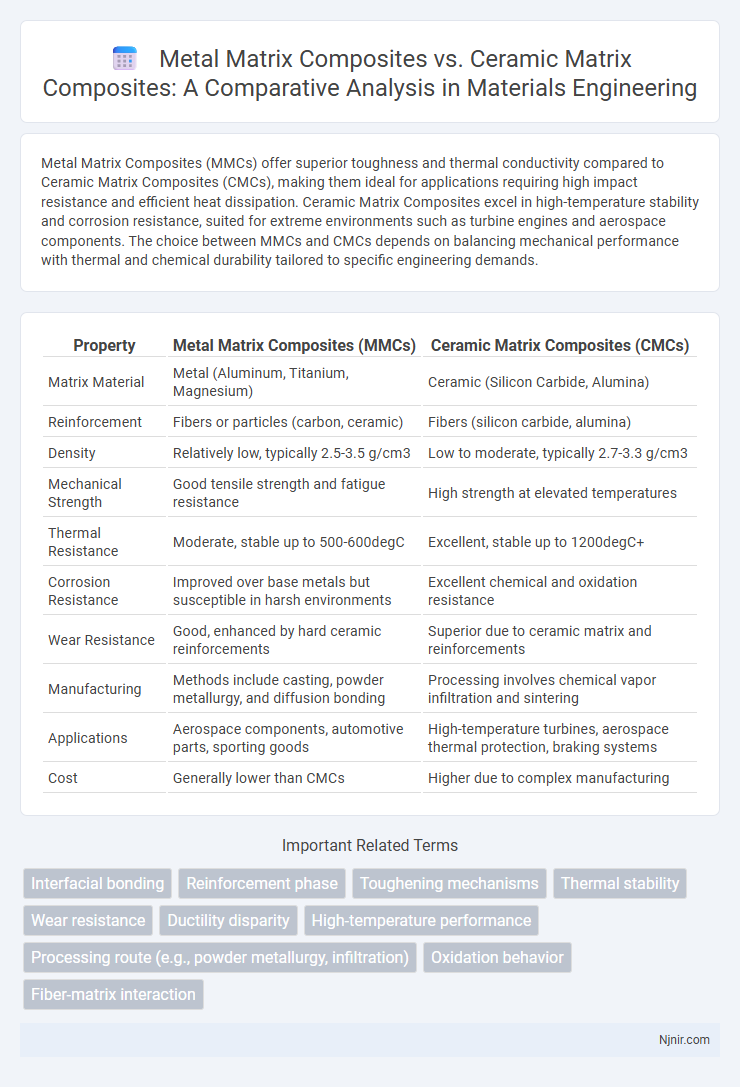

| Property | Metal Matrix Composites (MMCs) | Ceramic Matrix Composites (CMCs) |

|---|---|---|

| Matrix Material | Metal (Aluminum, Titanium, Magnesium) | Ceramic (Silicon Carbide, Alumina) |

| Reinforcement | Fibers or particles (carbon, ceramic) | Fibers (silicon carbide, alumina) |

| Density | Relatively low, typically 2.5-3.5 g/cm3 | Low to moderate, typically 2.7-3.3 g/cm3 |

| Mechanical Strength | Good tensile strength and fatigue resistance | High strength at elevated temperatures |

| Thermal Resistance | Moderate, stable up to 500-600degC | Excellent, stable up to 1200degC+ |

| Corrosion Resistance | Improved over base metals but susceptible in harsh environments | Excellent chemical and oxidation resistance |

| Wear Resistance | Good, enhanced by hard ceramic reinforcements | Superior due to ceramic matrix and reinforcements |

| Manufacturing | Methods include casting, powder metallurgy, and diffusion bonding | Processing involves chemical vapor infiltration and sintering |

| Applications | Aerospace components, automotive parts, sporting goods | High-temperature turbines, aerospace thermal protection, braking systems |

| Cost | Generally lower than CMCs | Higher due to complex manufacturing |

Introduction to Metal Matrix Composites and Ceramic Matrix Composites

Metal Matrix Composites (MMCs) consist of a metal or metal alloy matrix reinforced with ceramic fibers, particles, or whiskers, combining high strength and toughness with improved wear resistance and thermal conductivity. Ceramic Matrix Composites (CMCs) are composed of ceramic matrices reinforced with ceramic fibers to enhance fracture toughness and thermal stability at elevated temperatures, making them suitable for aerospace and high-performance applications. Both MMCs and CMCs aim to overcome the inherent brittleness of ceramics and enhance mechanical properties, but MMCs generally provide better ductility while CMCs excel in extreme thermal environments.

Structural Composition and Microstructure Differences

Metal matrix composites (MMCs) consist of a metallic matrix reinforced with ceramic fibers or particles, offering a ductile matrix with improved toughness and thermal conductivity. Ceramic matrix composites (CMCs) feature a brittle ceramic matrix reinforced with ceramic fibers, which significantly enhances fracture toughness and high-temperature stability. The microstructure of MMCs typically shows a continuous metal phase with dispersed ceramic reinforcements, while CMC microstructure displays a ceramic matrix with interlocked fibers that hinder crack propagation.

Key Material Properties and Performance Characteristics

Metal Matrix Composites (MMCs) exhibit superior toughness, high thermal conductivity, and excellent impact resistance, making them ideal for aerospace and automotive applications requiring lightweight strength. Ceramic Matrix Composites (CMCs) provide exceptional high-temperature stability, low density, and outstanding resistance to oxidation and wear, suitable for aerospace turbine engines and thermal protection systems. MMCs generally offer better ductility and toughness, while CMCs excel in thermal and chemical resistance, defining their performance across high-stress and high-temperature environments.

Manufacturing Techniques and Process Challenges

Metal Matrix Composites (MMCs) are commonly manufactured through processes such as powder metallurgy, stir casting, and squeeze casting, which offer control over fiber distribution but face challenges like achieving uniform reinforcement dispersion and preventing matrix-reinforcement reaction. Ceramic Matrix Composites (CMCs) utilize techniques including chemical vapor infiltration (CVI), polymer infiltration and pyrolysis (PIP), and melt infiltration, yet they encounter difficulties with controlling porosity, ensuring strong fiber-matrix bonding, and managing processing temperatures to avoid matrix cracking. Both MMCs and CMCs require precise process parameter optimization to balance mechanical properties and minimize defects inherent to their respective manufacturing methods.

Mechanical Behavior Under Stress and Load

Metal Matrix Composites (MMCs) exhibit superior toughness and impact resistance compared to Ceramic Matrix Composites (CMCs), making them ideal for applications requiring high ductility under dynamic loading conditions. Ceramic Matrix Composites demonstrate excellent high-temperature strength and stiffness but are more brittle, leading to lower fracture toughness under tensile and cyclic stresses. MMCs typically endure higher strain before failure, whereas CMCs maintain structural integrity at elevated temperatures with minimal creep, highlighting their distinct mechanical behavior under stress and load.

Thermal Stability and Conductivity Comparison

Metal Matrix Composites (MMCs) exhibit superior thermal conductivity due to the high heat transfer capability of metal matrices such as aluminum and titanium, making them suitable for applications requiring efficient heat dissipation. In contrast, Ceramic Matrix Composites (CMCs) offer exceptional thermal stability, maintaining structural integrity at temperatures exceeding 1200degC, which is critical for aerospace and turbine engine components. The thermal conductivity of CMCs is generally lower than MMCs, but their ability to withstand thermal shock and oxidation at elevated temperatures provides a distinct advantage in high-temperature environments.

Corrosion Resistance and Chemical Durability

Metal Matrix Composites (MMCs) offer moderate corrosion resistance, often enhanced by selecting corrosion-resistant metals like aluminum or titanium, but they may suffer galvanic corrosion when exposed to aggressive environments. Ceramic Matrix Composites (CMCs) exhibit superior chemical durability and corrosion resistance due to their inherently stable ceramic phases, making them ideal for high-temperature and oxidative environments. The chemical inertness of CMCs surpasses MMCs, enabling better performance in acidic or corrosive media, though MMCs provide better toughness and damage tolerance.

Typical Applications in Industry and Technology

Metal Matrix Composites (MMCs) are widely utilized in aerospace, automotive, and defense industries for components requiring high strength-to-weight ratios and excellent thermal conductivity, such as engine parts, brake rotors, and structural airframes. Ceramic Matrix Composites (CMCs) find typical applications in high-temperature environments like turbine blades, heat shields, and exhaust systems due to their exceptional thermal stability, corrosion resistance, and lightweight properties. Both MMCs and CMCs drive advancements in industrial technology by enhancing performance and durability under extreme conditions.

Cost Efficiency and Scalability of Production

Metal Matrix Composites (MMCs) offer cost efficiency and scalability advantages due to their compatibility with existing metal fabrication processes and relatively lower raw material costs compared to Ceramic Matrix Composites (CMCs). CMCs, while providing superior high-temperature resistance and lightweight properties, involve more complex manufacturing techniques such as chemical vapor infiltration, leading to higher production costs and limited scalability. In industrial applications where large-scale, cost-effective production is critical, MMCs are often preferred over CMCs despite the performance trade-offs.

Future Trends and Innovations in Composite Materials

Metal Matrix Composites (MMCs) and Ceramic Matrix Composites (CMCs) are advancing through innovations such as nano-reinforcements and additive manufacturing, enhancing mechanical properties and thermal stability for aerospace and automotive applications. Future trends emphasize lightweight structures, improved damage tolerance, and multifunctional capabilities integrating sensing and self-healing properties. These developments aim to address the growing demand for energy efficiency and high-performance materials in extreme environments.

Interfacial bonding

Metal Matrix Composites exhibit superior interfacial bonding strength due to ductile metal matrices enhancing load transfer, whereas Ceramic Matrix Composites face challenges in bonding because of brittle ceramic matrices and thermal expansion mismatch.

Reinforcement phase

Metal matrix composites feature ductile metallic reinforcements enhancing toughness, while ceramic matrix composites use ceramic reinforcements to improve high-temperature strength and wear resistance.

Toughening mechanisms

Metal Matrix Composites enhance toughness through plastic deformation and crack bridging, while Ceramic Matrix Composites improve toughness via crack deflection, fiber pull-out, and interface debonding mechanisms.

Thermal stability

Metal matrix composites offer superior thermal conductivity but lower thermal stability compared to ceramic matrix composites, which excel in maintaining structural integrity at high temperatures above 1000degC.

Wear resistance

Metal Matrix Composites exhibit superior wear resistance due to their enhanced toughness and ductility compared to the higher brittleness but excellent thermal stability of Ceramic Matrix Composites.

Ductility disparity

Metal Matrix Composites exhibit significantly higher ductility compared to Ceramic Matrix Composites due to the metallic matrix's ability to undergo plastic deformation, whereas ceramic matrices are inherently brittle and prone to fracture under stress.

High-temperature performance

Metal Matrix Composites exhibit superior thermal conductivity and toughness at high temperatures, while Ceramic Matrix Composites provide exceptional heat resistance and oxidation stability in extreme thermal environments.

Processing route (e.g., powder metallurgy, infiltration)

Metal Matrix Composites typically utilize powder metallurgy and infiltration processing routes for enhanced mechanical properties, whereas Ceramic Matrix Composites predominantly employ techniques like chemical vapor infiltration and slurry infiltration to achieve superior thermal and wear resistance.

Oxidation behavior

Metal Matrix Composites exhibit superior oxidation resistance at elevated temperatures compared to Ceramic Matrix Composites, due to the protective oxide layer formation on metal surfaces that reduces degradation.

Fiber-matrix interaction

Fiber-matrix interaction in Metal Matrix Composites (MMCs) typically enhances toughness and ductility through strong interfacial bonding, while in Ceramic Matrix Composites (CMCs), it primarily improves fracture resistance by promoting crack deflection and fiber bridging.

Metal Matrix Composites vs Ceramic Matrix Composites Infographic

njnir.com

njnir.com