Monocrystalline materials exhibit a uniform crystal lattice structure, resulting in superior mechanical strength and electronic properties compared to polycrystalline materials, which contain multiple grain boundaries that can act as sites for mechanical failure and electron scattering. The absence of grain boundaries in monocrystalline structures enhances thermal conductivity and electrical performance, making them ideal for high-performance semiconductor and photovoltaic applications. Polycrystalline materials, while generally more cost-effective and easier to produce, often show reduced efficiency and durability due to their heterogeneous grain structure.

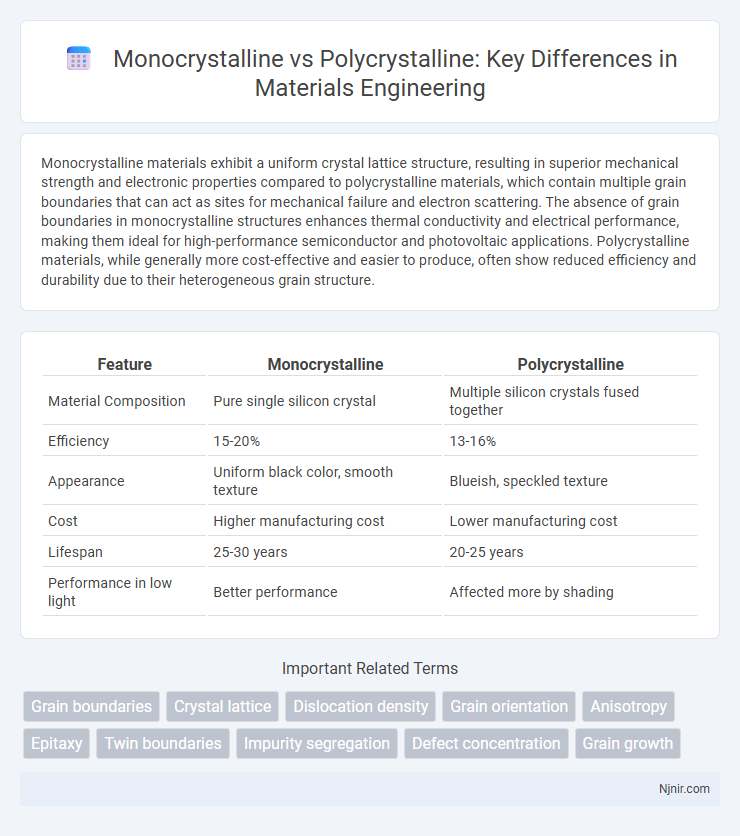

Table of Comparison

| Feature | Monocrystalline | Polycrystalline |

|---|---|---|

| Material Composition | Pure single silicon crystal | Multiple silicon crystals fused together |

| Efficiency | 15-20% | 13-16% |

| Appearance | Uniform black color, smooth texture | Blueish, speckled texture |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Lifespan | 25-30 years | 20-25 years |

| Performance in low light | Better performance | Affected more by shading |

Introduction to Crystalline Materials in Engineering

Monocrystalline materials consist of a single, continuous crystal lattice structure that provides superior electrical conductivity and mechanical strength, making them ideal for high-performance engineering applications. Polycrystalline materials are made up of multiple crystal grains or facets, which can introduce grain boundary weaknesses but often result in lower production costs and easier manufacturing processes. Engineers select between monocrystalline and polycrystalline materials based on the required balance of efficiency, durability, and cost-effectiveness in devices like solar panels, semiconductors, and structural components.

Defining Monocrystalline and Polycrystalline Structures

Monocrystalline solar cells consist of a single, continuous crystal lattice, resulting in higher efficiency and better performance in low-light conditions due to uniform electron mobility. Polycrystalline cells are composed of multiple silicon crystals melted together, which makes them less efficient but more cost-effective due to simpler manufacturing processes. The structural difference directly impacts durability, energy conversion rates, and overall system longevity.

Manufacturing Processes: Monocrystalline vs Polycrystalline

Monocrystalline solar panels are manufactured through the Czochralski process, which involves growing a single continuous crystal ingot from pure silicon, resulting in higher efficiency and uniformity. Polycrystalline panels are produced by melting multiple silicon fragments together, creating a less uniform crystal structure that lowers efficiency but reduces manufacturing complexity and cost. The differing grain structures directly affect performance, with monocrystalline cells providing better electrical conductivity and longevity due to their single-crystal composition.

Microstructural Differences and Their Impacts

Monocrystalline solar panels consist of single-crystal silicon with a uniform lattice structure, resulting in higher efficiency and better performance in low-light conditions due to reduced electron scattering. Polycrystalline panels are made from multiple silicon crystals, causing grain boundaries that increase electron recombination and reduce overall efficiency. The microstructural difference directly impacts the energy output, durability, and heat tolerance, with monocrystalline cells generally exhibiting superior performance and longevity.

Mechanical Properties Comparison

Monocrystalline solar panels exhibit superior mechanical strength and higher resistance to stress due to their uniform crystal structure, making them less prone to microcracks under mechanical load. Polycrystalline panels consist of multiple crystal grains and generally show lower mechanical durability, resulting in increased susceptibility to cell fracture and reduced lifespan under harsh environmental conditions. The enhanced mechanical stability of monocrystalline cells contributes to better long-term performance and reliability in demanding applications.

Electrical and Thermal Conductivity Analysis

Monocrystalline solar cells exhibit higher electrical conductivity due to their uniform crystal structure, allowing electrons to flow more freely with minimal resistance. Polycrystalline cells have lower electrical conductivity caused by grain boundaries that impede electron movement and increase recombination rates. In terms of thermal conductivity, monocrystalline materials conduct heat more efficiently, promoting better temperature management and improved performance stability under high operating temperatures compared to the less thermally conductive polycrystalline cells.

Cost and Scalability Considerations

Monocrystalline solar panels typically have a higher initial cost due to the complex manufacturing process involving single-crystal silicon, but they offer greater efficiency and longer lifespan. Polycrystalline panels are more cost-effective to produce, utilizing melted silicon fragments, which makes them appealing for large-scale installations where budget constraints are critical. When scaling solar projects, polycrystalline panels enable faster deployment and lower upfront investment, while monocrystalline panels provide superior energy yield per unit area.

Applications in Modern Materials Engineering

Monocrystalline silicon exhibits superior electrical conductivity and higher efficiency, making it ideal for high-performance solar panels and semiconductor devices in modern materials engineering. Polycrystalline silicon, with its lower production cost and slightly reduced efficiency, is widely used in consumer electronics and large-scale photovoltaic systems. Engineers select materials based on application-specific demands, balancing efficiency, cost, and manufacturing complexity.

Durability and Longevity: Performance Over Time

Monocrystalline solar panels typically offer higher durability and longer lifespan due to their single-crystal structure, which is less prone to microcracks and degradation under stress. Polycrystalline panels, composed of multiple silicon crystals, may experience slightly faster efficiency loss over time because of their inherent structural boundaries. Over the years, monocrystalline panels maintain superior performance and energy output, making them a preferred choice for long-term solar installations.

Future Trends in Crystalline Material Development

Future trends in crystalline material development emphasize enhancing efficiency and reducing costs of both monocrystalline and polycrystalline solar panels. Innovations in passivation techniques and heterojunction technology boost monocrystalline cell performance, while polycrystalline research focuses on improving grain boundary engineering to minimize recombination losses. Advanced manufacturing processes, including diamond wire sawing and high-purity silicon feedstock, drive scalability and sustainability in crystalline photovoltaic materials.

Grain boundaries

Monocrystalline solar cells have fewer grain boundaries, resulting in higher efficiency and better electron flow compared to polycrystalline cells, which contain multiple grain boundaries that can hinder performance.

Crystal lattice

Monocrystalline solar panels feature a uniform crystal lattice structure for higher efficiency, while polycrystalline panels have multiple crystal grains causing lattice boundaries that lower conductivity and efficiency.

Dislocation density

Monocrystalline solar cells exhibit significantly lower dislocation density compared to polycrystalline cells, resulting in higher efficiency and improved electrical performance.

Grain orientation

Monocrystalline solar panels feature a uniform grain orientation that enhances electron flow efficiency, whereas polycrystalline panels have multiple grain boundaries that reduce conductivity and overall performance.

Anisotropy

Monocrystalline solar cells exhibit lower anisotropy with uniform crystal orientation, enhancing efficiency compared to polycrystalline cells that have higher anisotropy due to varied grain orientations causing electron scattering and energy loss.

Epitaxy

Monocrystalline solar cells, produced through Epitaxy, achieve higher purity and efficiency compared to polycrystalline cells, which consist of multiple crystal grains leading to lower electron mobility.

Twin boundaries

Twin boundaries in monocrystalline solar cells enhance electron mobility and reduce recombination compared to the more defect-prone grain boundaries found in polycrystalline cells, improving overall efficiency.

Impurity segregation

Monocrystalline solar cells exhibit lower impurity segregation compared to polycrystalline cells, resulting in higher efficiency and better performance.

Defect concentration

Monocrystalline solar cells exhibit lower defect concentration compared to polycrystalline cells, resulting in higher efficiency and better performance.

Grain growth

Monocrystalline solar cells exhibit uniform grain growth with large single crystals, enhancing efficiency, while polycrystalline cells consist of multiple smaller grains causing grain boundaries that reduce electron mobility.

monocrystalline vs polycrystalline Infographic

njnir.com

njnir.com