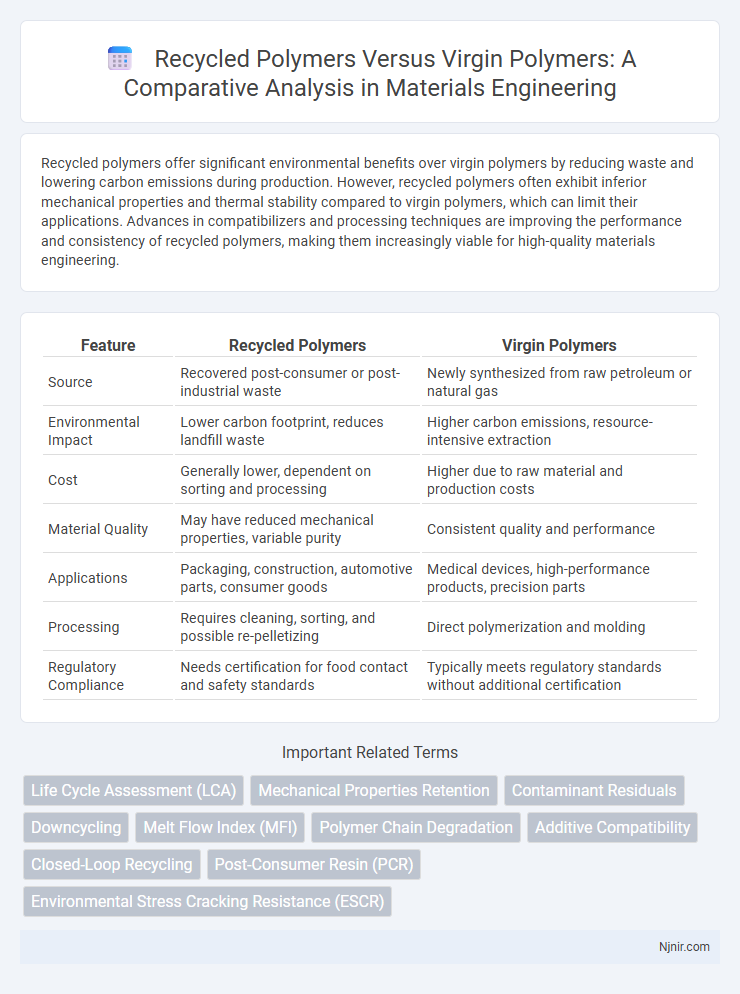

Recycled polymers offer significant environmental benefits over virgin polymers by reducing waste and lowering carbon emissions during production. However, recycled polymers often exhibit inferior mechanical properties and thermal stability compared to virgin polymers, which can limit their applications. Advances in compatibilizers and processing techniques are improving the performance and consistency of recycled polymers, making them increasingly viable for high-quality materials engineering.

Table of Comparison

| Feature | Recycled Polymers | Virgin Polymers |

|---|---|---|

| Source | Recovered post-consumer or post-industrial waste | Newly synthesized from raw petroleum or natural gas |

| Environmental Impact | Lower carbon footprint, reduces landfill waste | Higher carbon emissions, resource-intensive extraction |

| Cost | Generally lower, dependent on sorting and processing | Higher due to raw material and production costs |

| Material Quality | May have reduced mechanical properties, variable purity | Consistent quality and performance |

| Applications | Packaging, construction, automotive parts, consumer goods | Medical devices, high-performance products, precision parts |

| Processing | Requires cleaning, sorting, and possible re-pelletizing | Direct polymerization and molding |

| Regulatory Compliance | Needs certification for food contact and safety standards | Typically meets regulatory standards without additional certification |

Introduction to Polymers in Materials Engineering

Recycled polymers in materials engineering offer sustainable alternatives to virgin polymers by reprocessing post-consumer or industrial plastic waste into reusable materials, reducing reliance on fossil fuels and raw petrochemical extraction. Virgin polymers display consistent molecular weight and purity, enabling predictable mechanical properties crucial for high-performance applications, while recycled polymers may exhibit variability due to contamination and degradation during initial use and recycling processes. Optimizing polymer selection involves balancing environmental impact, material properties like tensile strength and thermal stability, and application-specific requirements in engineering design.

Defining Virgin vs. Recycled Polymers

Virgin polymers are newly synthesized materials derived directly from raw petrochemical feedstocks, ensuring consistent purity and mechanical properties. Recycled polymers consist of previously processed plastics that have been collected, sorted, cleaned, and reprocessed, often exhibiting variations in quality due to contamination or degradation. The distinction between virgin and recycled polymers centers on their source materials, with virgin polymers offering predictable performance and recycled polymers promoting sustainability by reducing environmental impact.

Manufacturing Processes: Virgin vs. Recycled Polymers

Manufacturing processes for virgin polymers involve the polymerization of monomers derived from petrochemical feedstocks, resulting in high-purity, consistent molecular structures ideal for precise applications. Recycled polymers undergo collection, sorting, cleaning, and reprocessing methods such as mechanical or chemical recycling, which may introduce variability in molecular weight and potential contaminants, affecting material performance. Innovations in advanced sorting technologies and chemical recycling techniques are improving the quality and consistency of recycled polymers, narrowing the gap with virgin polymer properties in manufacturing.

Mechanical Properties Comparison

Recycled polymers typically exhibit lower tensile strength and elongation at break compared to virgin polymers due to chain scission and contamination during the recycling process. However, advancements in recycling technologies and additive incorporation can enhance the mechanical properties of recycled polymers, narrowing the performance gap. Virgin polymers maintain superior mechanical consistency and higher impact resistance, making them preferable for applications demanding stringent material reliability.

Environmental Impact and Sustainability

Recycled polymers significantly reduce environmental impact by lowering greenhouse gas emissions and conserving fossil fuels compared to virgin polymers, which rely on raw petrochemical extraction. The use of recycled polymers supports circular economy principles by minimizing plastic waste and decreasing landfill contributions, contributing to sustainability goals. Though mechanical properties may vary, advances in recycling technologies have enhanced the performance and lifecycle of recycled polymers, making them viable alternatives in sustainable manufacturing.

Cost Efficiency and Economic Analysis

Recycled polymers typically offer cost savings of 20-40% compared to virgin polymers, driven by lower raw material expenses and reduced energy consumption during production. Economic analysis reveals that using recycled polymers can significantly decrease overall manufacturing costs while supporting circular economy goals by reducing landfill waste and conserving petrochemical resources. However, considerations such as potential variability in material properties and supply chain logistics impact the economic viability and must be factored into cost-benefit assessments.

Applications in Industry and Construction

Recycled polymers are increasingly utilized in construction for eco-friendly insulation, piping, and composite materials, offering cost-effective durability with reduced environmental impact. Virgin polymers provide consistent mechanical properties crucial for high-performance applications such as precision components and high-strength structural elements. Industry sectors are shifting towards recycled polymers to meet sustainability goals, while virgin polymers remain essential for specialized uses demanding stringent quality and reliability standards.

Challenges in Recycling Polymer Materials

Recycling polymer materials faces significant challenges such as contamination, which degrades the quality of recycled polymers compared to virgin polymers. The variability in polymer types and additives complicates sorting and processing, leading to inconsistent material properties. Furthermore, the degradation of polymer chains during recycling reduces mechanical strength and durability, limiting the applications of recycled polymers.

Innovations in Polymer Recycling Technologies

Innovations in polymer recycling technologies have significantly enhanced the efficiency and quality of recycled polymers, reducing reliance on virgin polymers derived from petrochemicals. Advanced chemical recycling methods, such as pyrolysis and depolymerization, enable the recovery of monomers with high purity, facilitating the production of recycled polymers with properties comparable to virgin materials. Enhanced sorting technologies and enzyme-based biodegradation further improve the sustainability and economic viability of polymer recycling, driving industry adoption and reducing plastic waste in the environment.

Future Trends in Sustainable Polymer Usage

Future trends in sustainable polymer usage emphasize the increasing adoption of recycled polymers due to advancements in chemical recycling technologies and improved sorting processes that enhance material quality and performance. Innovations in polymer design support compatibility between recycled and virgin polymers, enabling higher incorporation rates without compromising product integrity. Regulatory frameworks and consumer demand for environmentally friendly materials further drive investment in circular economy models, promoting closed-loop systems for polymer reuse.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) reveals that recycled polymers significantly reduce environmental impact compared to virgin polymers by lowering energy consumption, greenhouse gas emissions, and resource depletion throughout production and disposal phases.

Mechanical Properties Retention

Recycled polymers often exhibit reduced mechanical properties retention compared to virgin polymers due to degradation during processing and contamination, impacting tensile strength, elasticity, and durability.

Contaminant Residuals

Recycled polymers often contain higher levels of contaminant residuals compared to virgin polymers, impacting material purity and performance in advanced manufacturing applications.

Downcycling

Recycled polymers often undergo downcycling, resulting in lower-quality materials with reduced mechanical properties compared to virgin polymers.

Melt Flow Index (MFI)

Recycled polymers typically exhibit a higher Melt Flow Index (MFI) than virgin polymers due to thermal degradation and chain scission during processing.

Polymer Chain Degradation

Recycled polymers exhibit increased polymer chain degradation compared to virgin polymers, resulting in reduced molecular weight and compromised mechanical properties.

Additive Compatibility

Recycled polymers often exhibit reduced additive compatibility compared to virgin polymers due to impurities and molecular degradation affecting performance and processing stability.

Closed-Loop Recycling

Closed-loop recycling of recycled polymers preserves material quality and reduces environmental impact compared to virgin polymers by continuously reprocessing waste into identical new products without degradation.

Post-Consumer Resin (PCR)

Post-Consumer Resin (PCR) derived from recycled polymers significantly reduces environmental impact and energy consumption compared to virgin polymers while maintaining comparable material properties for sustainable manufacturing.

Environmental Stress Cracking Resistance (ESCR)

Recycled polymers often exhibit lower Environmental Stress Cracking Resistance (ESCR) compared to virgin polymers due to potential degradation and impurities affecting their molecular structure.

Recycled Polymers vs Virgin Polymers Infographic

njnir.com

njnir.com