Nanocomposites exhibit enhanced mechanical, thermal, and electrical properties due to their nanoscale filler reinforcements, which improve interfacial bonding and load transfer efficiency. Metal Matrix Composites (MMCs) provide superior strength and wear resistance by embedding ceramic or metallic reinforcements within a metal matrix, offering high structural stability at elevated temperatures. The choice between nanocomposites and MMCs depends on specific application requirements such as weight reduction, thermal conductivity, and performance under extreme mechanical stresses.

Table of Comparison

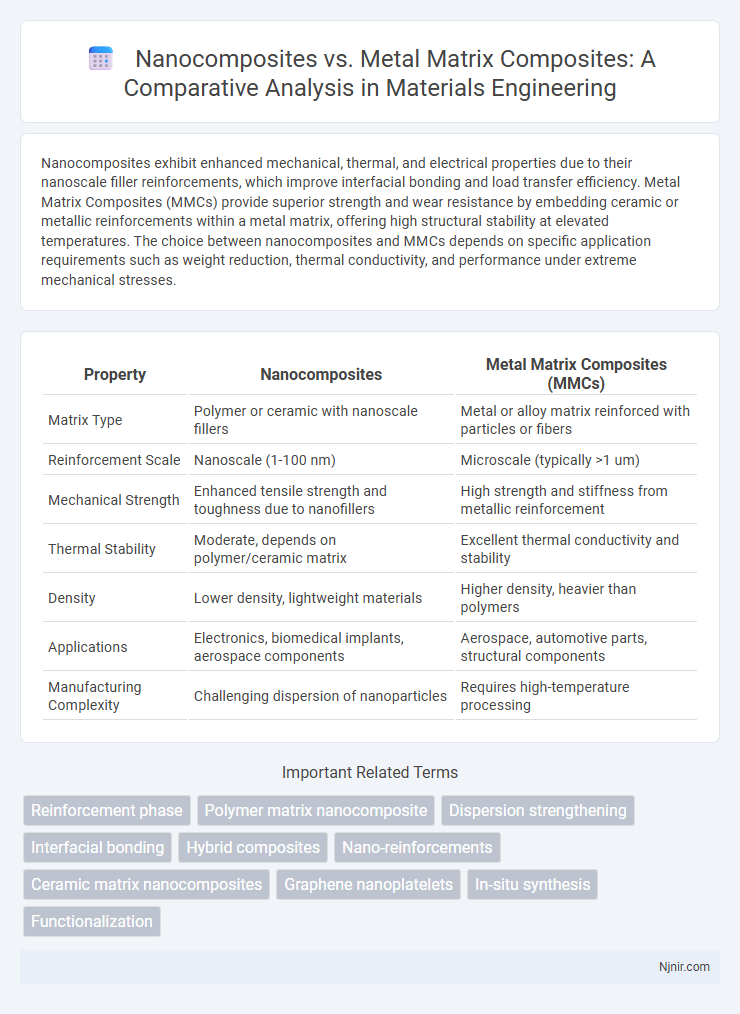

| Property | Nanocomposites | Metal Matrix Composites (MMCs) |

|---|---|---|

| Matrix Type | Polymer or ceramic with nanoscale fillers | Metal or alloy matrix reinforced with particles or fibers |

| Reinforcement Scale | Nanoscale (1-100 nm) | Microscale (typically >1 um) |

| Mechanical Strength | Enhanced tensile strength and toughness due to nanofillers | High strength and stiffness from metallic reinforcement |

| Thermal Stability | Moderate, depends on polymer/ceramic matrix | Excellent thermal conductivity and stability |

| Density | Lower density, lightweight materials | Higher density, heavier than polymers |

| Applications | Electronics, biomedical implants, aerospace components | Aerospace, automotive parts, structural components |

| Manufacturing Complexity | Challenging dispersion of nanoparticles | Requires high-temperature processing |

Introduction to Advanced Composite Materials

Nanocomposites exhibit enhanced mechanical, thermal, and electrical properties due to the incorporation of nanoparticles into a matrix, offering significant advantages over traditional composites. Metal Matrix Composites (MMCs) combine metal matrices with reinforcements like ceramics or fibers to achieve superior strength, wear resistance, and thermal stability for advanced engineering applications. Both nanocomposites and MMCs represent critical advancements in composite materials, enabling innovations in aerospace, automotive, and electronics industries through tailored properties and multifunctionality.

Defining Nanocomposites and Metal Matrix Composites

Nanocomposites consist of a polymer or ceramic matrix embedded with nanoparticles typically less than 100 nanometers in size, enhancing mechanical, thermal, and electrical properties due to high surface area and quantum effects. Metal Matrix Composites (MMCs) comprise a metal matrix reinforced with ceramic or metallic fibers, particles, or whiskers, providing improved stiffness, strength, and wear resistance compared to conventional metals. The key difference lies in the matrix material and reinforcement scale, with nanocomposites emphasizing nanoscale fillers and MMCs focusing on metallic matrices reinforced by micro- or nanoscale constituents.

Material Composition and Structural Differences

Nanocomposites incorporate nanoscale fillers such as carbon nanotubes, graphene, or nanoclays dispersed within a polymer or ceramic matrix, enhancing mechanical, thermal, and electrical properties due to their high surface area and quantum effects. Metal Matrix Composites (MMCs) consist of a continuous metallic matrix (e.g., aluminum, titanium, or magnesium) reinforced with ceramic particles, whiskers, or fibers that improve strength, stiffness, and wear resistance through load transfer mechanisms at the microscale. Structurally, nanocomposites feature a homogenous nanoscale dispersion promoting unique interface interactions, while MMCs exhibit distinct phase boundaries between the metal matrix and macroscopic reinforcements affecting toughness and thermal conductivity.

Synthesis and Fabrication Techniques

Nanocomposites are synthesized using techniques such as sol-gel processing, chemical vapor deposition, and in-situ polymerization, which enable precise dispersion of nanoparticles within the matrix. Metal Matrix Composites (MMCs) are primarily fabricated through methods like powder metallurgy, stir casting, and infiltration, focusing on achieving uniform reinforcement distribution within the metal base. Control over particle size, interfacial bonding, and thermal stability during synthesis directly influences the mechanical and thermal properties of both nanocomposites and MMCs.

Mechanical Properties Comparison

Nanocomposites exhibit superior mechanical properties such as enhanced tensile strength, stiffness, and impact resistance due to the uniform dispersion of nanoparticles within the matrix, which effectively hinders dislocation movement and crack propagation. Metal Matrix Composites (MMCs) provide improved mechanical performance including higher hardness, wear resistance, and thermal stability, primarily attributed to the reinforcement phases like ceramics or carbon fibers embedded in the metal matrix. Comparatively, nanocomposites excel in lightweight applications with improved ductility, while MMCs are preferable for high-load structural components requiring excellent thermal and mechanical stability.

Thermal and Electrical Performance

Nanocomposites exhibit superior thermal conductivity and enhanced electrical performance due to their high surface area and effective dispersion of nanoscale fillers, enabling efficient heat dissipation and electrical pathways. Metal Matrix Composites (MMCs) provide robust thermal stability and electrical conductivity by integrating metallic matrices with conductive reinforcements, suitable for high-temperature applications. Compared to MMCs, nanocomposites offer improved tunability in thermal and electrical properties through precise control of filler morphology and distribution at the nanoscale.

Corrosion and Wear Resistance

Nanocomposites exhibit superior corrosion resistance due to their nanoscale fillers that create denser, more uniform protective barriers against environmental degradation. Metal Matrix Composites (MMCs) provide enhanced wear resistance by incorporating ceramic or refractory particles that improve hardness and reduce material loss under friction. Both materials offer substantial improvements over traditional metals, with nanocomposites excelling in corrosion protection and MMCs delivering greater wear durability.

Applications in Aerospace, Automotive, and Electronics

Nanocomposites offer enhanced mechanical strength, corrosion resistance, and lightweight properties, making them ideal for aerospace applications such as structural components and thermal barrier coatings. Metal Matrix Composites (MMCs) provide superior wear resistance, thermal conductivity, and high-temperature performance, widely used in automotive engine parts, brake systems, and aerospace turbine blades. Electronics benefit from nanocomposites through improved thermal management and electrical conductivity, while MMCs contribute to heat sinks and connectors requiring robust mechanical integrity.

Cost, Scalability, and Sustainability

Nanocomposites generally offer lower material and processing costs compared to Metal Matrix Composites (MMCs) due to the use of nanoscale fillers and polymer matrices. Scalability for nanocomposites is typically higher, benefiting from established polymer manufacturing techniques, while MMCs require energy-intensive processes like casting or powder metallurgy that limit mass production. In terms of sustainability, nanocomposites often have a reduced environmental footprint due to lighter weight and potential for recyclability, whereas MMCs involve mining and metal refining with higher carbon emissions and resource depletion.

Future Trends and Research Directions

Nanocomposites are expected to revolutionize materials science with advancements in nanoscale reinforcements that enhance mechanical, thermal, and electrical properties beyond traditional Metal Matrix Composites (MMCs). Research is increasingly focusing on developing hybrid nanocomposites that combine nanoparticles, nanotubes, and graphene to achieve superior strength-to-weight ratios and multifunctionality. Future trends prioritize scalable manufacturing processes, environment-friendly synthesis, and integration of smart sensing capabilities for aerospace, automotive, and biomedical applications.

Reinforcement phase

Nanocomposites feature nanoscale reinforcements that significantly enhance mechanical, thermal, and electrical properties, whereas Metal Matrix Composites (MMCs) utilize microscale or larger reinforcements primarily to improve strength and wear resistance.

Polymer matrix nanocomposite

Polymer matrix nanocomposites enhance mechanical strength, thermal stability, and electrical conductivity compared to metal matrix composites due to their nanoscale filler dispersion and lightweight polymer matrix.

Dispersion strengthening

Nanocomposites achieve superior dispersion strengthening through nanoscale reinforcements that create a uniform distribution and hinder dislocation motion more effectively than the microscale particles typically used in metal matrix composites.

Interfacial bonding

Nanocomposites exhibit enhanced interfacial bonding due to their nanoscale reinforcement dispersion, resulting in superior mechanical properties compared to traditional Metal Matrix Composites with microscale interfaces.

Hybrid composites

Hybrid composites combining nanocomposites and metal matrix composites exhibit enhanced mechanical strength, thermal stability, and corrosion resistance, making them ideal for advanced aerospace and automotive applications.

Nano-reinforcements

Nano-reinforcements in nanocomposites significantly enhance mechanical, thermal, and electrical properties compared to traditional metal matrix composites by providing superior interfacial bonding and nanoscale load transfer efficiency.

Ceramic matrix nanocomposites

Ceramic matrix nanocomposites exhibit superior thermal stability, wear resistance, and mechanical strength compared to metal matrix composites, making them ideal for high-temperature and aerospace applications.

Graphene nanoplatelets

Graphene nanoplatelet-reinforced nanocomposites offer superior mechanical strength, thermal conductivity, and electrical properties compared to traditional metal matrix composites, enabling advanced lightweight structural applications.

In-situ synthesis

In-situ synthesis of nanocomposites typically offers superior interfacial bonding and uniform nanoparticle dispersion compared to metal matrix composites, resulting in enhanced mechanical strength and thermal stability.

Functionalization

Functionalization in nanocomposites enhances interfacial bonding and mechanical properties by modifying nanoparticle surfaces, whereas metal matrix composites rely on alloying elements and coating techniques to improve compatibility and performance.

Nanocomposites vs Metal Matrix Composites Infographic

njnir.com

njnir.com