PEEK (Polyether Ether Ketone) and PEKK (Polyether Ketone Ketone) are high-performance polymers widely used in materials engineering for applications requiring exceptional strength, chemical resistance, and thermal stability. PEKK offers enhanced mechanical properties and better thermal resistance compared to PEEK due to its ketone-rich molecular structure, making it more suitable for aerospace and medical implants. The choice between PEEK and PEKK depends on specific application demands, with PEKK providing improved processability and stiffness while PEEK remains favored for its well-established performance and cost-effectiveness.

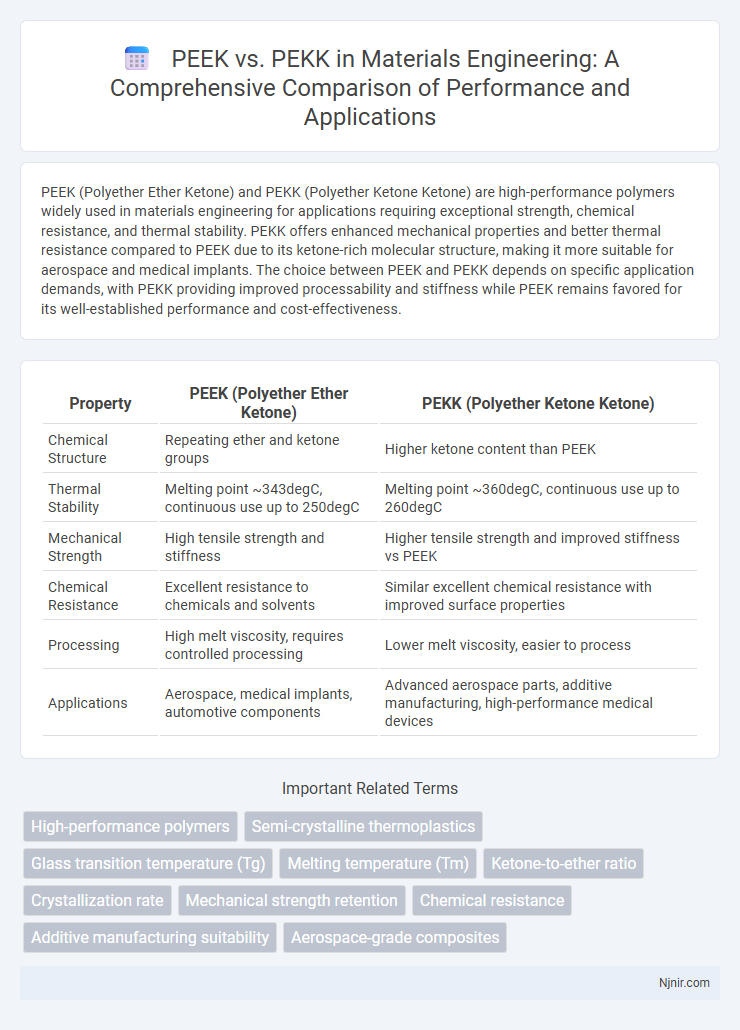

Table of Comparison

| Property | PEEK (Polyether Ether Ketone) | PEKK (Polyether Ketone Ketone) |

|---|---|---|

| Chemical Structure | Repeating ether and ketone groups | Higher ketone content than PEEK |

| Thermal Stability | Melting point ~343degC, continuous use up to 250degC | Melting point ~360degC, continuous use up to 260degC |

| Mechanical Strength | High tensile strength and stiffness | Higher tensile strength and improved stiffness vs PEEK |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Similar excellent chemical resistance with improved surface properties |

| Processing | High melt viscosity, requires controlled processing | Lower melt viscosity, easier to process |

| Applications | Aerospace, medical implants, automotive components | Advanced aerospace parts, additive manufacturing, high-performance medical devices |

Introduction to PEEK and PEKK

PEEK (Polyether ether ketone) is a high-performance thermoplastic known for its excellent mechanical strength, chemical resistance, and thermal stability, commonly used in aerospace, medical implants, and automotive industries. PEKK (Polyether ketone ketone) offers similar high-temperature resistance but with enhanced toughness and faster crystallization rates, making it suitable for more demanding applications requiring improved durability and processability. Both polymers belong to the polyaryletherketone (PAEK) family, distinguished by their molecular structure which dictates their thermal and mechanical properties.

Chemical Structure and Composition

PEEK (Polyether Ether Ketone) features a linear aromatic polymer chain composed of repeating ether and ketone groups, providing high thermal stability and chemical resistance. PEKK (Polyether Ketone Ketone) contains a similar backbone but alternates ketone and ether linkages more frequently, resulting in higher rigidity and melting temperature. The increased ketone content in PEKK enhances crystallinity and mechanical strength compared to PEEK, influencing its processability and performance in high-demand applications.

Mechanical Properties Comparison

PEEK exhibits high tensile strength around 90-100 MPa and excellent fatigue resistance, making it suitable for demanding mechanical applications. PEKK offers superior compressive strength up to 120 MPa and higher heat deflection temperature, enhancing performance under extreme thermal and load conditions. Both materials provide outstanding chemical resistance and stiffness, with PEKK showing improved impact resistance and dimensional stability compared to PEEK.

Thermal Stability and Performance

PEEK (Polyether Ether Ketone) and PEKK (Polyether Ketone Ketone) are high-performance thermoplastics known for exceptional thermal stability, with PEEK exhibiting a continuous service temperature up to 250degC and PEKK reaching slightly higher at around 260degC. PEKK offers superior thermal performance due to its ketone group arrangement, resulting in higher glass transition temperature and enhanced chemical resistance compared to PEEK. Both materials maintain mechanical integrity under high temperatures, but PEKK's improved thermal resistance and faster crystallization rates make it preferable for applications demanding extreme thermal stability and rapid processing.

Processing Techniques and Ease of Fabrication

PEEK and PEKK differ significantly in processing techniques and ease of fabrication due to their distinct thermal properties; PEEK typically requires higher processing temperatures around 370degC, while PEKK melts at lower temperatures near 305degC, making it easier to mold and shape. PEKK exhibits faster crystallization rates, enabling shorter cycle times during injection molding and offering improved dimensional stability compared to PEEK. These factors contribute to PEKK's greater versatility in additive manufacturing and thermoforming applications, whereas PEEK is preferred for applications demanding higher thermal resistance and mechanical strength.

Chemical Resistance and Environmental Stability

PEEK exhibits excellent chemical resistance, maintaining structural integrity against acids, bases, and organic solvents, making it suitable for harsh chemical environments. PEKK offers superior environmental stability with enhanced resistance to hydrolysis, UV radiation, and thermal degradation, extending its durability in extreme conditions. Both polymers demonstrate high-performance characteristics, but PEKK's improved resistance to environmental factors provides a strategic advantage in demanding industrial applications.

Applications in Industry

PEEK and PEKK are high-performance polymers widely used in aerospace, automotive, and medical industries due to their exceptional thermal stability and chemical resistance. PEEK excels in applications requiring continuous use at temperatures up to 250degC, such as engine components and medical implants, while PEKK offers enhanced mechanical strength and faster crystallization, making it ideal for 3D printing and aerospace structural parts. Both materials support lightweight construction and durability, driving innovation in demanding industrial environments.

Cost and Availability

PEEK (Polyether Ether Ketone) generally has a higher market availability with numerous suppliers worldwide, while PEKK (Polyether Ketone Ketone) remains less common and can be harder to source. Regarding cost, PEKK typically commands a premium price due to its more complex synthesis process and newer market presence, whereas PEEK is comparatively more affordable because of its established production scale. Industries requiring advanced thermal and chemical resistance balance the higher PEKK cost against its enhanced material properties.

Advantages and Limitations

PEEK (Polyether Ether Ketone) offers high chemical resistance, mechanical strength, and excellent thermal stability up to 250degC, making it ideal for aerospace and medical applications. PEKK (Polyether Ketone Ketone) provides superior mechanical properties, higher heat resistance reaching 300degC, and better processability due to its ketone content, benefiting advanced manufacturing like 3D printing. Limitations of PEEK include higher melt viscosity limiting complex shapes, whereas PEKK can be more expensive and may require precise processing conditions to optimize performance.

Future Trends in PEEK and PEKK Development

PEEK and PEKK are advancing with innovations in enhanced thermal stability and mechanical strength, targeting aerospace, automotive, and medical industries. Research emphasizes improving bio-compatibility and eco-friendly production methods to meet sustainability goals and regulatory standards. Emerging applications leverage additive manufacturing and nanocomposite integration to expand the functional capabilities of both polymers.

High-performance polymers

PEEK offers superior chemical resistance and mechanical strength for high-performance polymer applications, while PEKK provides enhanced thermal stability and faster crystallization rates ideal for advanced engineering uses.

Semi-crystalline thermoplastics

PEEK offers higher chemical resistance and mechanical strength, while PEKK provides greater thermal stability and faster crystallization among semi-crystalline thermoplastics.

Glass transition temperature (Tg)

PEKK exhibits a higher glass transition temperature (Tg) of approximately 162degC compared to PEEK's Tg of around 143degC, making PEKK more suitable for high-temperature applications.

Melting temperature (Tm)

PEKK has a higher melting temperature (Tm) of approximately 305degC compared to PEEK's melting temperature (Tm) of about 343degC, making PEKK more suitable for high-temperature applications.

Ketone-to-ether ratio

PEEK contains a ketone-to-ether ratio of approximately 1:1, offering balanced thermal stability and flexibility, while PEKK has a higher ketone-to-ether ratio around 2:1, providing enhanced thermal resistance and mechanical strength.

Crystallization rate

PEKK exhibits a slower crystallization rate than PEEK, resulting in improved processability and enhanced thermal stability for high-performance applications.

Mechanical strength retention

PEKK exhibits superior mechanical strength retention compared to PEEK, maintaining higher tensile and impact resistance under prolonged thermal and chemical stress.

Chemical resistance

PEEK exhibits superior chemical resistance to hydrocarbons and acids, while PEKK offers enhanced resistance to strong bases and exhibits higher thermal stability.

Additive manufacturing suitability

PEKK exhibits higher thermal stability and chemical resistance than PEEK, making it more suitable for high-performance additive manufacturing applications requiring enhanced mechanical properties.

Aerospace-grade composites

PEEK offers superior thermal stability and chemical resistance while PEKK provides enhanced mechanical strength and faster processing times, making both aerospace-grade composites essential for high-performance structural applications.

PEEK vs PEKK Infographic

njnir.com

njnir.com