Powder metallurgy offers superior control over microstructure and material properties compared to conventional casting, enabling the production of components with fine, uniform grain size and minimal porosity. This technique reduces material waste and allows for the fabrication of complex shapes with tight tolerances that are difficult to achieve through casting. Enhanced mechanical strength and wear resistance are often realized in powder metallurgy parts, making them ideal for high-performance applications.

Table of Comparison

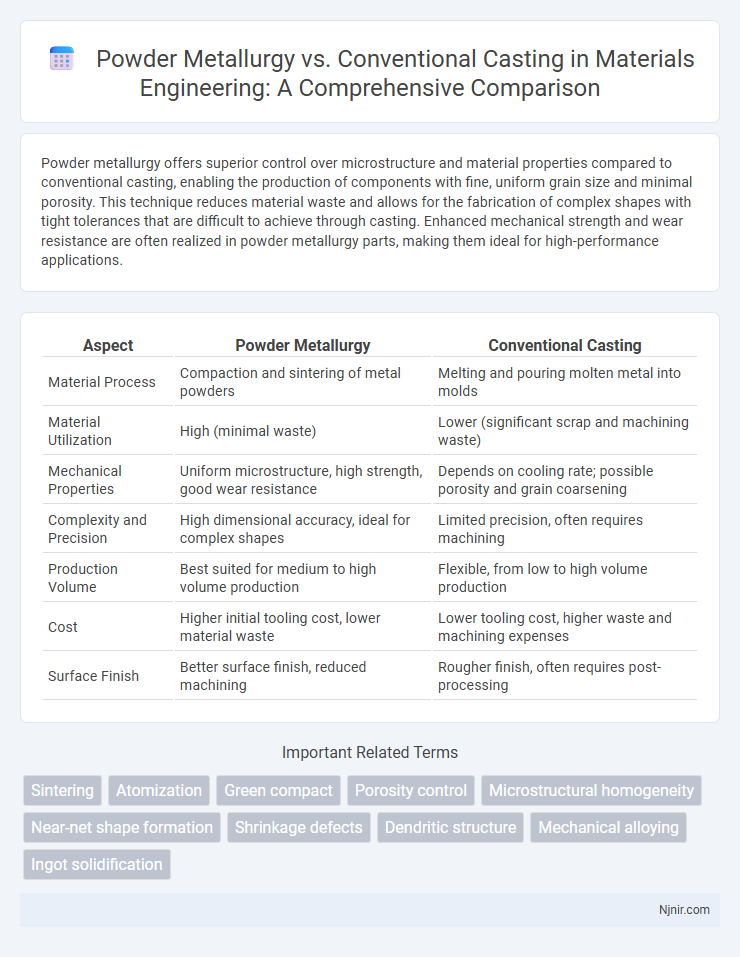

| Aspect | Powder Metallurgy | Conventional Casting |

|---|---|---|

| Material Process | Compaction and sintering of metal powders | Melting and pouring molten metal into molds |

| Material Utilization | High (minimal waste) | Lower (significant scrap and machining waste) |

| Mechanical Properties | Uniform microstructure, high strength, good wear resistance | Depends on cooling rate; possible porosity and grain coarsening |

| Complexity and Precision | High dimensional accuracy, ideal for complex shapes | Limited precision, often requires machining |

| Production Volume | Best suited for medium to high volume production | Flexible, from low to high volume production |

| Cost | Higher initial tooling cost, lower material waste | Lower tooling cost, higher waste and machining expenses |

| Surface Finish | Better surface finish, reduced machining | Rougher finish, often requires post-processing |

Introduction to Powder Metallurgy and Conventional Casting

Powder metallurgy involves fabricating metal components by compacting and sintering metal powders, offering precise control over composition and microstructure for enhanced mechanical properties. Conventional casting melts metal into a liquid state, pouring it into molds to solidify, which allows the creation of complex shapes but often leads to grain structure inconsistencies and porosity. The choice between powder metallurgy and casting depends on desired part performance, dimensional accuracy, and production volume.

Fundamental Principles of Each Process

Powder metallurgy operates on the principle of compacting metal powders into a desired shape followed by sintering at high temperatures to achieve metallurgical bonding without melting the base material. Conventional casting involves melting metal into a liquid state and pouring it into molds where it solidifies into the final shape, relying on phase change from liquid to solid. While powder metallurgy offers superior control over microstructure and material properties with minimal waste, conventional casting provides flexibility for complex geometries but is prone to defects such as porosity and shrinkage.

Material Selection and Compatibility

Powder metallurgy offers superior material selection flexibility, enabling the production of complex alloys and composite materials with precise control over microstructure and porosity compared to conventional casting. Conventional casting often requires materials with good fluidity and viscosity to ensure defect-free molds, limiting compatibility with certain high-melting-point or reactive metals. The controlled environment in powder metallurgy enhances compatibility with advanced materials like superalloys and refractory metals, which are challenging for conventional casting due to thermal stresses and segregation issues.

Microstructural Differences

Powder metallurgy produces finer and more homogeneous microstructures with uniform grain sizes due to controlled particle size and sintering processes, unlike conventional casting which often results in coarser grains with dendritic structures and segregation due to slower cooling rates. The absence of large grain boundaries in powder metallurgy enhances mechanical properties like strength and wear resistance. In contrast, conventional casting microstructures commonly exhibit porosity and non-metallic inclusions that can act as stress concentrators, reducing material performance.

Mechanical Properties Comparison

Powder metallurgy often yields superior mechanical properties compared to conventional casting due to its finer microstructure and reduced porosity, resulting in higher strength and hardness. The controlled particle size and sintering process in powder metallurgy enhance tensile strength and wear resistance beyond what is typically achievable in cast components. Conventional casting may suffer from defects like shrinkage and segregation, leading to lower ductility and toughness relative to powder metallurgy-produced parts.

Process Efficiency and Cost Analysis

Powder metallurgy offers higher process efficiency through near-net shape manufacturing, reducing material waste and machining time compared to conventional casting. Casting processes often involve longer cycle times and require significant post-processing, increasing labor and operational costs. Cost analysis reveals powder metallurgy excels in producing complex parts with consistent properties at lower overall production costs for medium-to-high volume runs.

Design Flexibility and Complexity

Powder metallurgy offers superior design flexibility and complexity by enabling the production of intricate shapes and fine details that are difficult or impossible to achieve with conventional casting. This process allows precise control over material composition and microstructure, resulting in complex geometries with minimal machining and material waste. Conventional casting tends to face limitations with undercuts, thin walls, and internal cavities, often requiring additional machining or assembly steps to achieve complex designs.

Environmental Impact and Sustainability

Powder metallurgy produces less material waste and requires lower energy consumption compared to conventional casting, leading to a smaller carbon footprint in manufacturing processes. The near-net-shape capability of powder metallurgy minimizes scrap and reduces the need for secondary machining, enhancing resource efficiency and sustainability. Conventional casting generates more emissions due to higher melting temperatures and often results in significant post-processing waste, making it less environmentally favorable.

Typical Applications in Industry

Powder metallurgy is widely used in aerospace, automotive, and medical industries for producing components with complex shapes, high strength, and excellent wear resistance, such as turbine blades, gears, and orthopedic implants. Conventional casting remains dominant in heavy machinery, construction, and shipbuilding sectors for manufacturing large, intricate parts like engine blocks, pump housings, and propellers due to its cost-effectiveness and ability to handle diverse alloys. Both methods cater to different industrial needs, with powder metallurgy excelling in precision and material efficiency, while casting supports large-scale, robust structural components.

Future Trends and Technological Advances

Powder metallurgy is evolving rapidly with advances in additive manufacturing and nanotechnology, enabling finer microstructures and improved material properties compared to conventional casting. Future trends highlight the integration of AI for process optimization and real-time quality control in powder metallurgy, offering enhanced precision and reduced waste. Conventional casting continues to develop with improved alloy compositions and mold materials but faces limitations in achieving the same level of detail and mechanical performance as emerging powder metallurgy techniques.

Sintering

Powder metallurgy utilizes sintering to enhance metal particle bonding and uniform microstructure, resulting in superior mechanical properties compared to conventional casting, which relies on solidification and often experiences coarser grain structures and porosity.

Atomization

Atomization in powder metallurgy produces finer, more uniform metal powders compared to the coarser, less consistent microstructure typical of conventional casting, enhancing material strength and precision.

Green compact

Green compacts in powder metallurgy exhibit superior dimensional accuracy and reduced porosity compared to conventional casting, enhancing mechanical properties and minimizing post-processing requirements.

Porosity control

Powder metallurgy offers superior porosity control compared to conventional casting by enabling precise particle size distribution and compaction parameters, resulting in enhanced material density and mechanical properties.

Microstructural homogeneity

Powder metallurgy produces superior microstructural homogeneity compared to conventional casting by enabling finer grain size control and uniform distribution of alloying elements.

Near-net shape formation

Powder metallurgy enables precise near-net shape formation by compacting metal powders into complex geometries with minimal machining, whereas conventional casting often requires extensive post-processing to achieve final dimensions due to shrinkage and surface defects.

Shrinkage defects

Powder metallurgy produces minimal shrinkage defects compared to conventional casting due to its near-net shape manufacturing and controlled solidification process.

Dendritic structure

Powder metallurgy produces a homogeneous microstructure without dendritic patterns, whereas conventional casting typically results in a coarse dendritic structure due to slower solidification rates.

Mechanical alloying

Mechanical alloying in powder metallurgy offers superior microstructural control and enhanced mechanical properties compared to conventional casting methods.

Ingot solidification

Powder metallurgy produces uniform microstructures with minimal segregation during ingot solidification, unlike conventional casting, which often results in coarse grains and elemental segregation due to slower cooling rates.

Powder metallurgy vs Conventional casting Infographic

njnir.com

njnir.com