High-entropy alloys exhibit superior mechanical properties and enhanced thermal stability compared to traditional alloys due to their complex multi-element compositions. These alloys demonstrate remarkable resistance to wear, corrosion, and oxidation, making them suitable for extreme environments. Their unique microstructural characteristics enable improved strength and ductility, surpassing conventional alloy limitations.

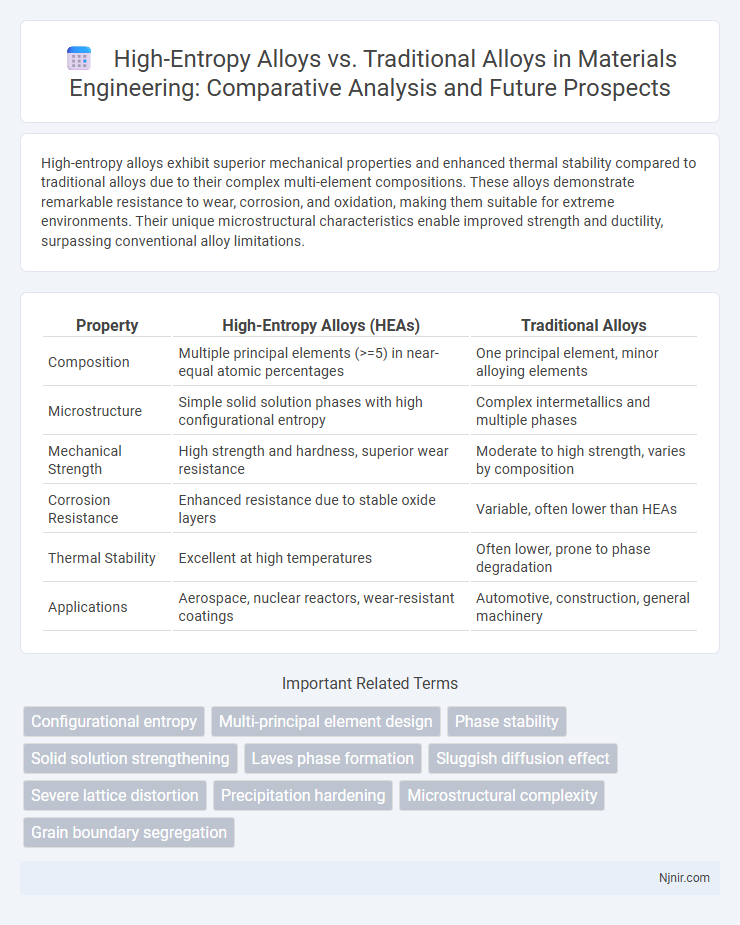

Table of Comparison

| Property | High-Entropy Alloys (HEAs) | Traditional Alloys |

|---|---|---|

| Composition | Multiple principal elements (>=5) in near-equal atomic percentages | One principal element, minor alloying elements |

| Microstructure | Simple solid solution phases with high configurational entropy | Complex intermetallics and multiple phases |

| Mechanical Strength | High strength and hardness, superior wear resistance | Moderate to high strength, varies by composition |

| Corrosion Resistance | Enhanced resistance due to stable oxide layers | Variable, often lower than HEAs |

| Thermal Stability | Excellent at high temperatures | Often lower, prone to phase degradation |

| Applications | Aerospace, nuclear reactors, wear-resistant coatings | Automotive, construction, general machinery |

Introduction to Alloys: Definitions and Classifications

Alloys are metallic materials composed of two or more elements, categorized primarily into traditional alloys, which have one principal element with minor additions, and high-entropy alloys (HEAs), characterized by multiple principal elements in near-equiatomic proportions. Traditional alloys, such as steel (iron-based) and bronze (copper-based), rely on dominant base metals modified to enhance specific properties. High-entropy alloys exhibit unique microstructures and enhanced mechanical, thermal, and corrosion resistance due to their complex multi-element compositions, marking a paradigm shift in alloy design and classification.

Fundamental Principles of High-Entropy Alloys

High-entropy alloys (HEAs) differ fundamentally from traditional alloys by incorporating five or more principal elements in near-equiatomic proportions, promoting high configurational entropy that stabilizes simple solid solution phases over complex intermetallic compounds. This unique compositional complexity enhances phase stability, mechanical strength, and corrosion resistance due to sluggish diffusion and lattice distortion effects. The foundational principle of HEAs relies on maximizing entropy to achieve superior performance characteristics unattainable in conventional alloy systems dominated by one or two primary elements.

Composition and Microstructural Differences

High-entropy alloys (HEAs) consist of five or more principal elements mixed in near-equiatomic proportions, unlike traditional alloys which typically have one primary base metal with minor additive elements. The complex, multi-component composition of HEAs results in unique microstructures characterized by simple solid-solution phases such as face-centered cubic (FCC) or body-centered cubic (BCC), whereas traditional alloys often exhibit complex intermetallic compounds and secondary phases. These compositional and microstructural differences lead to distinct mechanical and physical properties, making HEAs promising for advanced applications.

Mechanical Properties Comparison

High-entropy alloys (HEAs) exhibit superior mechanical properties such as enhanced strength, hardness, and wear resistance compared to traditional alloys due to their multi-principal element composition and severe lattice distortion. The high configurational entropy in HEAs leads to exceptional phase stability and improved resistance to deformation mechanisms like dislocation motion and grain boundary sliding. In contrast, traditional alloys, typically based on one or two principal elements, often face limitations in achieving comparable strength-ductility combinations and high-temperature performance.

Corrosion and Oxidation Resistance

High-entropy alloys (HEAs) exhibit superior corrosion and oxidation resistance compared to traditional alloys due to their complex multi-element compositions that form stable passive oxide layers. The high configurational entropy in HEAs reduces elemental diffusion rates, enhancing the stability of protective surface films under harsh environments. This intrinsic property results in improved durability and lifespan for applications exposed to aggressive corrosive and oxidative conditions.

Processing Techniques and Manufacturing

High-entropy alloys (HEAs) require advanced processing techniques such as rapid solidification, powder metallurgy, and additive manufacturing to achieve their complex, multi-element microstructures, which differ significantly from the traditional casting and forging methods used for conventional alloys. These sophisticated manufacturing processes enable precise control over phase formation and elemental distribution, enhancing mechanical properties and thermal stability of HEAs. Traditional alloys benefit from well-established, cost-effective processing routes, but often lack the microstructural complexity and tailored performance achievable through the innovative manufacturing methods applied to HEAs.

Thermal Stability and Performance

High-entropy alloys exhibit superior thermal stability compared to traditional alloys due to their multi-element composition, which enhances resistance to phase transformations and grain growth at elevated temperatures. This stability results in improved mechanical performance, including higher strength and creep resistance under extreme thermal conditions. Consequently, high-entropy alloys are increasingly preferred in aerospace and energy industries where materials face harsh thermal environments.

Applications in Modern Engineering

High-entropy alloys (HEAs) exhibit superior mechanical properties, corrosion resistance, and thermal stability compared to traditional alloys, making them ideal for aerospace, automotive, and energy sectors. Their complex multi-element compositions enable enhanced wear resistance and strength at elevated temperatures, outperforming conventional alloy systems such as steel and titanium alloys. Industries increasingly adopt HEAs for critical components like turbine blades, engine parts, and structural materials, driving advancements in performance and durability.

Cost and Sustainability Considerations

High-entropy alloys (HEAs) often incur higher initial costs due to their complex multi-element compositions and specialized processing techniques compared to traditional alloys, which typically utilize fewer elements and established manufacturing methods. The sustainability advantages of HEAs stem from their potential for enhanced durability, corrosion resistance, and extended service life, reducing material waste and frequency of replacements. In contrast, traditional alloys may rely on more abundant resources but can lead to increased environmental impact over time due to shorter lifespans and greater resource consumption.

Future Trends and Research Directions

High-entropy alloys (HEAs) are revolutionizing materials science with their exceptional mechanical properties, thermal stability, and corrosion resistance compared to traditional alloys. Future research is heavily focused on optimizing HEA compositions through machine learning algorithms and high-throughput experiments to tailor properties for aerospace, energy, and biomedical applications. Innovations in additive manufacturing techniques are enabling complex HEA structures, driving advancements in lightweight, high-strength components with enhanced durability.

Configurational entropy

High-entropy alloys exhibit significantly higher configurational entropy than traditional alloys, enhancing their phase stability and mechanical properties at elevated temperatures.

Multi-principal element design

High-entropy alloys leverage multi-principal element design by incorporating five or more elements in near-equal atomic percentages, resulting in enhanced mechanical properties and thermal stability compared to traditional alloys with one or two dominant elements.

Phase stability

High-entropy alloys exhibit enhanced phase stability due to their multi-element composition and high configurational entropy, reducing phase separation compared to traditional alloys with fewer elements.

Solid solution strengthening

High-entropy alloys exhibit superior solid solution strengthening compared to traditional alloys due to their multi-principal element compositions, which create severe lattice distortions and hinder dislocation movement more effectively.

Laves phase formation

High-entropy alloys exhibit suppressed Laves phase formation compared to traditional alloys due to their complex multi-element compositions, enhancing phase stability and mechanical properties.

Sluggish diffusion effect

High-entropy alloys exhibit significantly slower atomic diffusion rates compared to traditional alloys due to their complex multi-element compositions, enhancing their thermal stability and mechanical properties.

Severe lattice distortion

High-entropy alloys exhibit severe lattice distortion due to their multi-principal element composition, enhancing mechanical strength and thermal stability compared to traditional alloys with simpler lattice structures.

Precipitation hardening

High-entropy alloys exhibit enhanced precipitation hardening compared to traditional alloys due to their complex multi-element composition, which promotes the formation of stable, fine precipitates that significantly improve mechanical strength and thermal stability.

Microstructural complexity

High-entropy alloys exhibit significantly greater microstructural complexity than traditional alloys due to their multi-principal element compositions, resulting in unique phase distributions and enhanced mechanical properties.

Grain boundary segregation

High-entropy alloys exhibit reduced grain boundary segregation compared to traditional alloys due to their complex multi-element composition, which enhances grain boundary stability and corrosion resistance.

high-entropy alloys vs traditional alloys Infographic

njnir.com

njnir.com