Phase change materials (PCMs) absorb and release thermal energy during phase transitions, making them highly effective for thermal energy storage and temperature regulation applications. Shape memory alloys (SMAs) exhibit unique mechanical properties, such as the ability to return to a pre-deformed shape when heated, which enables their use in actuators, sensors, and biomedical devices. The choice between PCMs and SMAs depends on the specific application requirements related to thermal management or mechanical response.

Table of Comparison

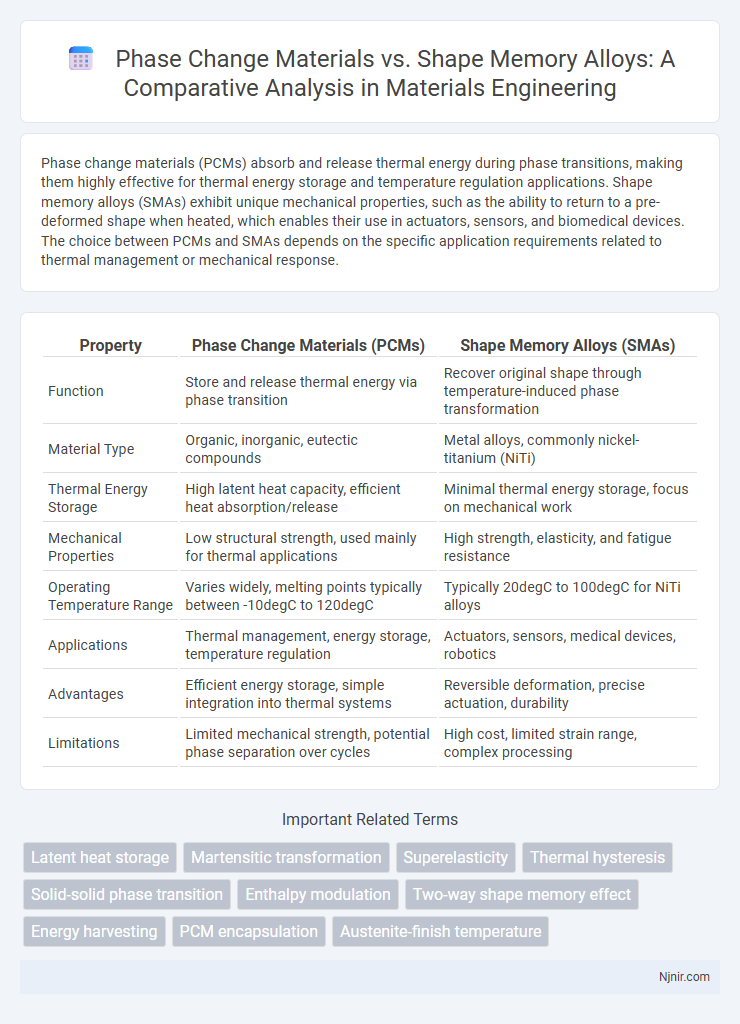

| Property | Phase Change Materials (PCMs) | Shape Memory Alloys (SMAs) |

|---|---|---|

| Function | Store and release thermal energy via phase transition | Recover original shape through temperature-induced phase transformation |

| Material Type | Organic, inorganic, eutectic compounds | Metal alloys, commonly nickel-titanium (NiTi) |

| Thermal Energy Storage | High latent heat capacity, efficient heat absorption/release | Minimal thermal energy storage, focus on mechanical work |

| Mechanical Properties | Low structural strength, used mainly for thermal applications | High strength, elasticity, and fatigue resistance |

| Operating Temperature Range | Varies widely, melting points typically between -10degC to 120degC | Typically 20degC to 100degC for NiTi alloys |

| Applications | Thermal management, energy storage, temperature regulation | Actuators, sensors, medical devices, robotics |

| Advantages | Efficient energy storage, simple integration into thermal systems | Reversible deformation, precise actuation, durability |

| Limitations | Limited mechanical strength, potential phase separation over cycles | High cost, limited strain range, complex processing |

Introduction to Phase Change Materials and Shape Memory Alloys

Phase change materials (PCMs) store and release thermal energy through reversible phase transitions, typically between solid and liquid states, making them highly efficient for thermal energy management. Shape memory alloys (SMAs) are metallic compounds that exhibit a unique ability to return to a pre-defined shape when exposed to specific temperature changes, driven by a solid-solid phase transformation known as the martensitic transformation. Both PCMs and SMAs play critical roles in energy storage, thermal regulation, and smart actuator applications due to their distinct phase-dependent properties.

Fundamental Principles: Phase Transformation Mechanisms

Phase change materials (PCMs) undergo solid-liquid phase transformations based on thermal energy absorption or release, enabling latent heat storage through reversible melting and solidification processes. Shape memory alloys (SMAs) exhibit solid-solid phase transformations between martensite and austenite phases, driven by temperature or stress changes, resulting in reversible deformation and shape recovery. The fundamental mechanism in PCMs centers on latent heat during phase changes, while SMAs rely on crystallographic rearrangements enabling shape memory and superelastic properties.

Comparative Analysis of Material Properties

Phase change materials (PCMs) exhibit high latent heat storage capacity, enabling efficient thermal energy absorption and release during phase transitions, whereas shape memory alloys (SMAs) demonstrate exceptional mechanical properties such as superelasticity and shape recovery through thermo-mechanical cycling. PCMs typically operate within specific temperature ranges defined by their melting points, making them ideal for thermal regulation, while SMAs function through reversible martensitic transformations, providing actuation and structural adaptability. The thermal conductivity of SMAs is generally higher than that of PCMs, influencing response times and energy efficiency in applications involving temperature fluctuations or mechanical stress-induced transformations.

Thermal Energy Storage Capabilities

Phase change materials (PCMs) offer high latent heat storage capacity by absorbing or releasing thermal energy during phase transitions, making them highly efficient for thermal energy storage applications. Shape memory alloys (SMAs) store thermal energy through reversible solid-state phase transformations, but their energy density is generally lower compared to PCMs. PCMs excel in large-scale thermal energy storage systems due to their ability to maintain nearly constant temperatures during phase change, while SMAs are more suited for actuation and sensing applications with moderate heat storage requirements.

Mechanical and Functional Applications

Phase change materials (PCMs) excel in thermal energy storage applications by absorbing or releasing latent heat during solid-liquid transitions, while shape memory alloys (SMAs) provide exceptional actuation and mechanical performance through reversible phase transformations in their crystalline structure. PCMs primarily enhance thermal regulation in building materials and electronics, whereas SMAs are widely used in aerospace, robotics, and medical devices for their shape recovery and high fatigue resistance. Mechanical applications leverage SMAs for adaptive components and damping systems, whereas PCMs contribute functionally in temperature control and energy-efficient systems.

Durability and Fatigue Resistance

Phase change materials (PCMs) exhibit excellent durability under thermal cycling due to their ability to repeatedly absorb and release latent heat without significant degradation, making them highly resistant to fatigue in temperature-dependent applications. Shape memory alloys (SMAs) demonstrate exceptional mechanical durability and fatigue resistance through their ability to undergo numerous reversible phase transformations between martensite and austenite phases, allowing them to maintain performance under repeated mechanical stress. While PCMs excel in thermal energy storage with minimal fatigue, SMAs provide superior mechanical fatigue resistance critical for applications involving cyclic loading and deformation.

Integration in Smart Systems and Devices

Phase change materials (PCMs) offer efficient thermal energy storage and management through reversible phase transitions, making them ideal for temperature regulation in smart systems and devices. Shape memory alloys (SMAs) provide precise mechanical actuation by returning to predefined shapes upon thermal stimulus, enabling adaptive structural components and responsive mechanisms. Integrating PCMs and SMAs in smart technologies enhances multi-functional performance by combining thermal control with dynamic actuation for advanced, energy-efficient applications.

Environmental Impact and Sustainability

Phase change materials (PCMs) offer high energy efficiency through latent heat storage with minimal environmental footprint, relying on non-toxic, recyclable substances that promote sustainability in thermal management applications. Shape memory alloys (SMAs), composed primarily of metals like nickel-titanium, entail more intensive mining and processing impacts, although their durability and recyclability contribute to long-term sustainability. Lifecycle assessments highlight PCMs' lower greenhouse gas emissions during production, while SMAs provide resilience but require careful consideration of resource extraction and end-of-life recycling practices.

Challenges in Manufacturing and Processing

Phase change materials (PCMs) face challenges in manufacturing due to their susceptibility to leakage and degradation over repeated thermal cycles, requiring robust encapsulation techniques to maintain stability. Shape memory alloys (SMAs) encounter difficulties in processing because precise control of alloy composition and thermomechanical treatment is essential for consistent phase transformation and shape memory effects. Both materials demand advanced fabrication methods to ensure performance reliability, with PCMs needing enhanced containment and SMAs requiring meticulous control over microstructure and mechanical properties.

Future Trends and Research Directions

Future trends in phase change materials emphasize enhancing thermal energy storage capacity and cycling stability for renewable energy applications. Research directions for shape memory alloys focus on improving fatigue resistance and biocompatibility to expand their use in medical implants and aerospace actuators. Integrating nanoscale composites and smart control systems represents a promising avenue to optimize performance in both material classes.

Latent heat storage

Phase change materials store latent heat through solid-liquid transitions with high energy density and rapid thermal response, while shape memory alloys utilize solid-solid phase changes offering lower latent heat storage but higher mechanical energy conversion efficiency.

Martensitic transformation

Martensitic transformation enables shape memory alloys to exhibit reversible deformation and shape recovery, whereas phase change materials primarily undergo reversible thermal phase changes without mechanical shape memory effects.

Superelasticity

Shape memory alloys exhibit superior superelasticity compared to phase change materials, enabling reversible strain recovery up to 8% without permanent deformation.

Thermal hysteresis

Phase change materials exhibit lower thermal hysteresis compared to shape memory alloys, enabling faster and more efficient thermal energy storage and release.

Solid-solid phase transition

Solid-solid phase transitions in phase change materials enable reversible thermal energy storage, whereas shape memory alloys exhibit mechanical transformation for actuation due to their martensitic-austenitic phase shifts.

Enthalpy modulation

Phase change materials exhibit higher enthalpy modulation through latent heat absorption and release during phase transitions, while shape memory alloys modulate enthalpy primarily via reversible martensitic transformations with associated strain energy changes.

Two-way shape memory effect

Shape memory alloys exhibit a two-way shape memory effect enabling reversible phase transformations between martensite and austenite, while phase change materials primarily rely on latent heat storage without intrinsic reversible mechanical deformation.

Energy harvesting

Phase change materials efficiently store and release thermal energy through reversible solid-liquid transitions, while shape memory alloys convert mechanical deformation into electrical energy, making both integral yet distinct for energy harvesting applications.

PCM encapsulation

Encapsulating phase change materials (PCMs) enhances thermal energy storage efficiency by preventing leakage and improving stability, whereas shape memory alloys (SMAs) inherently rely on reversible solid-state phase transformations without requiring encapsulation.

Austenite-finish temperature

Shape memory alloys exhibit a precise Austenite-finish temperature crucial for reversible phase transformation, whereas phase change materials primarily rely on thermal energy storage without a defined Austenite-finish point.

Phase change materials vs Shape memory alloys Infographic

njnir.com

njnir.com