Nanoceramics exhibit exceptional hardness and thermal stability due to their nanoscale grain structures, making them ideal for high-temperature applications. Nanocomposites combine nanosized ceramic particles with polymer or metal matrices to enhance mechanical strength and toughness while maintaining lightweight properties. The tailored interface between the ceramic nanoparticles and the matrix enables superior performance in wear resistance and fracture toughness compared to conventional materials.

Table of Comparison

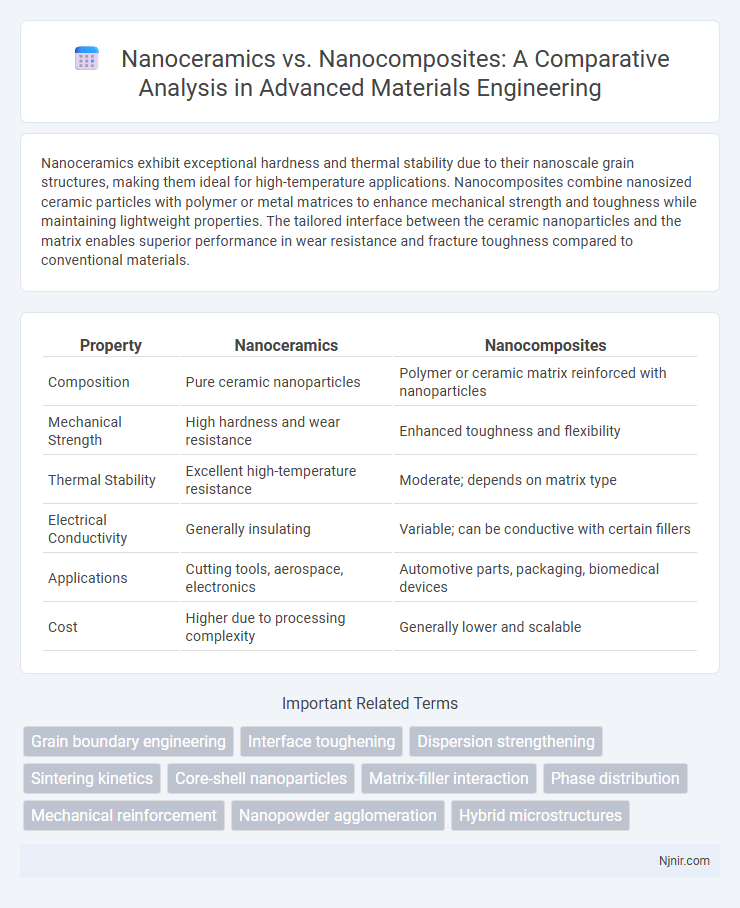

| Property | Nanoceramics | Nanocomposites |

|---|---|---|

| Composition | Pure ceramic nanoparticles | Polymer or ceramic matrix reinforced with nanoparticles |

| Mechanical Strength | High hardness and wear resistance | Enhanced toughness and flexibility |

| Thermal Stability | Excellent high-temperature resistance | Moderate; depends on matrix type |

| Electrical Conductivity | Generally insulating | Variable; can be conductive with certain fillers |

| Applications | Cutting tools, aerospace, electronics | Automotive parts, packaging, biomedical devices |

| Cost | Higher due to processing complexity | Generally lower and scalable |

Introduction to Nanoceramics and Nanocomposites

Nanoceramics are advanced materials composed of ceramic particles with nanometer-scale dimensions, offering exceptional mechanical strength, thermal stability, and chemical resistance. Nanocomposites combine nanoparticles, such as nanoceramics, with a matrix material to enhance properties like toughness, flexibility, and conductivity, surpassing traditional composites. Both nanoceramics and nanocomposites play crucial roles in developing lightweight, high-performance materials for applications in aerospace, electronics, and biomedical fields.

Defining Features: Nanoceramics vs Nanocomposites

Nanoceramics are advanced materials primarily composed of ceramic nanoparticles characterized by high hardness, thermal stability, and chemical inertness, making them ideal for applications requiring wear resistance and heat endurance. Nanocomposites integrate ceramic, polymer, or metal nanoparticles into a matrix to enhance mechanical, electrical, or thermal properties through synergistic effects between matrix and filler materials. The defining feature of nanoceramics lies in their homogeneous nanoparticle-based ceramic structure, whereas nanocomposites distinguish themselves by combining multiple phases at the nanoscale to achieve tailored multifunctional properties.

Synthesis Methods in Nanoceramics and Nanocomposites

Synthesis methods for nanoceramics primarily include sol-gel processing, hydrothermal synthesis, and chemical vapor deposition, enabling precise control over particle size and phase purity. In nanocomposites, synthesis often involves combining nanopowders or in situ formation of nanoparticles within a matrix via techniques such as ball milling, polymer melt compounding, or co-precipitation to achieve enhanced mechanical and thermal properties. Tailoring synthesis routes in both nanoceramics and nanocomposites is crucial for optimizing microstructure, interfacial bonding, and functional performance in advanced material applications.

Microstructural Differences and Characterization

Nanoceramics exhibit a homogeneous microstructure composed of nanosized ceramic grains, while nanocomposites consist of a heterogeneous architecture combining nanoscale ceramic and polymer or metal phases. Characterization techniques such as transmission electron microscopy (TEM), scanning electron microscopy (SEM), and X-ray diffraction (XRD) reveal distinct grain size distributions and interphase boundaries in nanocomposites compared to the uniform grain morphology in nanoceramics. These microstructural differences significantly influence mechanical properties, thermal stability, and fracture behavior observed through spectroscopy and nanoindentation analyses.

Mechanical Properties Comparison

Nanoceramics exhibit exceptional hardness and high wear resistance due to their densely packed nanostructures, making them ideal for applications requiring superior mechanical strength and thermal stability. Nanocomposites integrate nanoceramic particles with polymer or metal matrices, enhancing toughness and fracture resistance while maintaining lightweight characteristics. The combination of these materials in nanocomposites provides a balanced improvement in mechanical properties, including increased tensile strength and impact resistance compared to pure nanoceramics.

Thermal Stability and Conductivity Insights

Nanoceramics exhibit superior thermal stability due to their densely packed crystalline structures, enabling them to withstand higher temperatures without degradation. Nanocomposites, combining nanoparticles within a matrix, offer enhanced thermal conductivity by facilitating efficient heat transfer pathways through their heterogeneous interfaces. Understanding the distinct thermal properties of nanoceramics and nanocomposites is crucial for applications in electronics, aerospace, and energy systems requiring optimized heat resistance and dissipation.

Functional Applications in Modern Industries

Nanoceramics exhibit exceptional hardness, thermal stability, and corrosion resistance, making them ideal for applications in aerospace, electronics, and biomedical implants where durability and precision are critical. Nanocomposites combine nanoparticles with polymer or metal matrices to enhance mechanical strength, electrical conductivity, and thermal resistance, extensively used in automotive parts, flexible electronics, and packaging industries. The functional versatility and tailored properties of nanoceramics and nanocomposites drive innovation in sectors requiring advanced performance materials.

Environmental Impact and Sustainability

Nanoceramics offer superior durability and wear resistance, reducing the need for frequent replacements and lowering environmental waste over time. Nanocomposites combine nanoparticles with polymers or metals, enhancing mechanical properties while enabling the use of recycled or bio-based materials, contributing to sustainability. Both materials present challenges in recycling and potential nanoparticle release, requiring ongoing research to minimize environmental impact and ensure safe lifecycle management.

Future Trends in Nanoceramics and Nanocomposites

Future trends in nanoceramics emphasize enhanced thermal stability, improved mechanical strength, and multifunctional applications in aerospace and biomedical implants. Nanocomposites are advancing through tailored interfaces and hybrid nanofillers, enabling superior electrical conductivity, flexibility, and self-healing properties for flexible electronics and energy storage devices. Integration of machine learning and sustainable synthesis methods is driving innovation in both nanoceramics and nanocomposites, optimizing performance and environmental impact.

Challenges and Opportunities in Material Advancement

Nanoceramics face challenges related to brittleness and fabrication complexity, yet offer significant opportunities in high-temperature stability and wear resistance for advanced engineering applications. Nanocomposites present obstacles in achieving uniform nanoparticle dispersion and interfacial bonding but enable enhanced mechanical strength, electrical conductivity, and multifunctionality through synergistic properties of matrix and reinforcement phases. Advancements in synthesis techniques and surface modification strategies continue to drive innovation in both nanoceramics and nanocomposites, expanding their potential in aerospace, biomedical, and energy storage sectors.

Grain boundary engineering

Grain boundary engineering in nanoceramics enhances mechanical strength and thermal stability by optimizing grain size and boundary characteristics, while in nanocomposites, it improves interfacial bonding and multifunctional properties through tailored microstructural design.

Interface toughening

Nanoceramics exhibit enhanced interface toughening through strong atomic bonding and grain boundary refinement, while nanocomposites achieve interface toughening by incorporating nanoscale reinforcements that improve load transfer and crack deflection.

Dispersion strengthening

Nanocomposites exhibit superior dispersion strengthening compared to nanoceramics due to the uniform distribution of nanoscale reinforcements within the matrix, enhancing mechanical properties and resistance to deformation.

Sintering kinetics

Nanoceramics exhibit faster sintering kinetics due to their homogeneous nano-scale grain structure, while nanocomposites demonstrate slower sintering rates influenced by heterogeneous phase distribution and interfacial effects.

Core-shell nanoparticles

Core-shell nanoparticles in nanoceramics provide enhanced thermal and mechanical properties by combining a ceramic core with a functional shell, whereas in nanocomposites they enable multifunctional performance through tailored interfaces between distinct material phases.

Matrix-filler interaction

Nanoceramics exhibit strong matrix-filler bonding due to their homogeneous ceramic phases enhancing mechanical properties, whereas nanocomposites rely on diverse matrix-filler interactions between polymer or metal matrices and nanofillers to achieve tailored multifunctional performance.

Phase distribution

Nanoceramics exhibit a homogeneous phase distribution of nanoscale ceramic grains, while nanocomposites feature a heterogeneous phase distribution combining nanoscale ceramics with distinct polymer or metal matrices to enhance mechanical and thermal properties.

Mechanical reinforcement

Nanoceramics provide superior mechanical reinforcement through enhanced hardness and wear resistance, while nanocomposites offer improved toughness and flexibility by combining ceramic nanoparticles with polymer or metal matrices.

Nanopowder agglomeration

Nanopowder agglomeration significantly impacts the mechanical properties and dispersion quality in nanoceramics and nanocomposites, with nanoceramics often requiring advanced de-agglomeration techniques to enhance sintering and achieve uniform microstructures.

Hybrid microstructures

Nanoceramics exhibit superior hardness and thermal stability due to their uniform crystalline structure, while nanocomposites with hybrid microstructures combine ceramic and polymer phases to enhance toughness and multifunctional properties.

Nanoceramics vs Nanocomposites Infographic

njnir.com

njnir.com