Nanocellulose and cellulose nanocrystals (CNCs) are both derived from cellulose but differ significantly in structure and properties. Nanocellulose typically presents as a web-like network of cellulose fibrils with high aspect ratios, offering exceptional mechanical strength and flexibility, whereas CNCs are rod-like crystalline nanoparticles with rigid, highly ordered structures that provide superior stiffness and thermal stability. These distinctions make nanocellulose ideal for applications requiring toughness and flexibility, while CNCs are preferred in reinforcing composites and developing advanced nanomaterials.

Table of Comparison

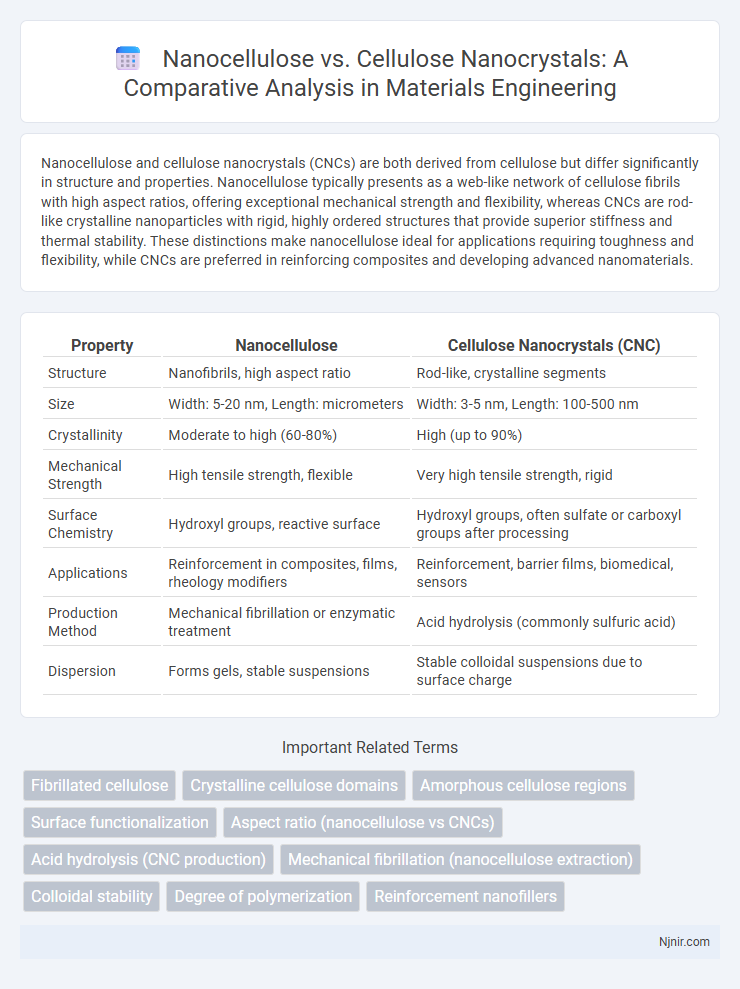

| Property | Nanocellulose | Cellulose Nanocrystals (CNC) |

|---|---|---|

| Structure | Nanofibrils, high aspect ratio | Rod-like, crystalline segments |

| Size | Width: 5-20 nm, Length: micrometers | Width: 3-5 nm, Length: 100-500 nm |

| Crystallinity | Moderate to high (60-80%) | High (up to 90%) |

| Mechanical Strength | High tensile strength, flexible | Very high tensile strength, rigid |

| Surface Chemistry | Hydroxyl groups, reactive surface | Hydroxyl groups, often sulfate or carboxyl groups after processing |

| Applications | Reinforcement in composites, films, rheology modifiers | Reinforcement, barrier films, biomedical, sensors |

| Production Method | Mechanical fibrillation or enzymatic treatment | Acid hydrolysis (commonly sulfuric acid) |

| Dispersion | Forms gels, stable suspensions | Stable colloidal suspensions due to surface charge |

Introduction to Nanocellulose and Cellulose Nanocrystals

Nanocellulose encompasses a range of nanoscale cellulose materials derived from plant fibers, including cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs). Cellulose nanocrystals are rigid, rod-like nanoparticles obtained through acid hydrolysis of cellulose, characterized by high crystallinity and exceptional mechanical strength. These nanoscale entities exhibit unique properties such as biodegradability, high surface area, and tunable surface chemistry, making them suitable for applications in composites, biomedical devices, and sustainable materials.

Structural Differences between Nanocellulose and Cellulose Nanocrystals

Nanocellulose comprises a broad category of cellulose-based nanomaterials, including cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs), distinguished by their morphology and extraction processes. Cellulose nanocrystals exhibit a highly crystalline structure with a rigid, rod-like shape, derived primarily through acid hydrolysis, which removes amorphous regions and enhances crystalline domains. Nanocellulose generally contains both crystalline and amorphous regions, resulting in a network of entangled fibrils with higher flexibility and aspect ratio compared to the strictly crystalline, shorter, and stiffer CNCs.

Extraction and Production Methods

Nanocellulose and cellulose nanocrystals (CNCs) are derived from cellulose but differ significantly in extraction and production methods. Nanocellulose is typically produced via mechanical fibrillation processes such as high-pressure homogenization, grinding, or microfluidization, which preserve the fibrillar network structure. In contrast, CNCs are primarily obtained through acid hydrolysis, commonly using sulfuric acid, to selectively remove amorphous regions, yielding rigid, rod-like crystalline nanoparticles.

Physical and Chemical Properties Comparison

Nanocellulose exhibits a fibrillar structure with high aspect ratio and flexibility, while cellulose nanocrystals (CNCs) have rod-like shapes with rigid crystalline regions. Chemically, nanocellulose contains both amorphous and crystalline domains, resulting in variable reactivity, whereas CNCs are predominantly crystalline with hydroxyl groups readily available for surface modification. The thermal stability of CNCs is generally higher due to their ordered crystalline structure, contrasting with the lower thermal degradation onset in the more heterogeneous nanocellulose.

Mechanical Performance and Reinforcement Capabilities

Nanocellulose and Cellulose Nanocrystals (CNCs) exhibit distinct mechanical performance attributes, with CNCs offering higher tensile strength and stiffness due to their crystalline structure. CNCs provide superior reinforcement capabilities in composite materials, significantly enhancing mechanical properties such as Young's modulus and tensile strength compared to nanocellulose fibrils. The enhanced load transfer efficiency of CNCs makes them ideal for applications requiring high mechanical performance and stiffness.

Applications in Advanced Materials

Nanocellulose and Cellulose Nanocrystals (CNCs) play crucial roles in advanced materials due to their exceptional mechanical strength, biodegradability, and high surface area. Nanocellulose is widely used in flexible electronics, reinforcing composites, and barrier films for packaging, while CNCs are preferred for biomedical applications, optical devices, and as rheology modifiers in coatings and adhesives. Their unique nanoscale properties enable innovations in lightweight, sustainable materials with enhanced performance and functionality.

Surface Modification Techniques

Nanocellulose and cellulose nanocrystals (CNCs) both possess hydroxyl-rich surfaces that enable diverse surface modification techniques such as TEMPO-mediated oxidation, silylation, and graft polymerization to enhance their functionality. Surface modifications improve properties like dispersibility in solvents, compatibility with polymer matrices, and reactive sites for further chemical functionalization, essential in applications ranging from composites to biomedical fields. These tailored surface chemistries significantly impact the mechanical strength, thermal stability, and hydrophilicity of nanocellulose-based materials.

Environmental Impact and Sustainability

Nanocellulose and cellulose nanocrystals (CNCs) differ in their environmental impact, with nanocellulose exhibiting higher biodegradability and lower energy requirements during production compared to CNCs. Both materials derive from renewable biomass sources, but nanocellulose's simpler extraction processes reduce chemical usage, enhancing sustainability. Lifecycle assessments highlight nanocellulose's potential to minimize carbon footprint and waste generation in green material applications.

Challenges in Commercial Scale-Up

Nanocellulose and cellulose nanocrystals (CNCs) face significant challenges in commercial scale-up, including high production costs and complex extraction processes requiring specialized equipment. Variability in raw biomass sources impacts product consistency, while difficulties in achieving uniform dispersion and stability during large-scale processing hinder integration into industrial applications. Regulatory uncertainties and the need for sustainable, eco-friendly manufacturing further complicate market adoption of these nanomaterials.

Future Prospects in Materials Engineering

Nanocellulose and cellulose nanocrystals (CNCs) offer transformative potential in materials engineering due to their biodegradability, high strength-to-weight ratio, and renewable nature. Future developments focus on enhancing CNCs' functionalization for advanced composites, smart materials, and sustainable packaging solutions, leveraging their nanoscale dimensions for improved mechanical and barrier properties. Nanocellulose integration into flexible electronics, biomedical devices, and environmentally friendly construction materials is projected to drive innovation in green technology and circular economy frameworks.

Fibrillated cellulose

Fibrillated cellulose, often referred to as nanocellulose, differs from cellulose nanocrystals in its longer, entangled nanofiber structure that provides enhanced mechanical strength and flexibility for advanced material applications.

Crystalline cellulose domains

Nanocellulose exhibits a broader range of crystalline cellulose domains with varying morphologies, whereas cellulose nanocrystals consist predominantly of highly ordered crystalline regions extracted from cellulose fibers.

Amorphous cellulose regions

Nanocellulose contains higher proportions of amorphous cellulose regions compared to cellulose nanocrystals, which largely consist of highly crystalline cellulose structures.

Surface functionalization

Nanocellulose exhibits versatile surface functionalization options through chemical modifications like TEMPO oxidation, enhancing hydrophilicity and reactivity, whereas Cellulose Nanocrystals primarily allow sulfate ester group introduction via sulfuric acid hydrolysis, providing distinct surface charge properties for applications in composites and biomedical fields.

Aspect ratio (nanocellulose vs CNCs)

Nanocellulose typically exhibits a higher aspect ratio, ranging from 50 to 100, whereas cellulose nanocrystals (CNCs) have a lower aspect ratio typically between 5 and 20, influencing their mechanical properties and applications.

Acid hydrolysis (CNC production)

Acid hydrolysis efficiently produces cellulose nanocrystals (CNCs) by selectively hydrolyzing amorphous regions of cellulose nanocellulose, resulting in highly crystalline rod-like nanoparticles with superior mechanical and optical properties.

Mechanical fibrillation (nanocellulose extraction)

Mechanical fibrillation effectively extracts nanocellulose by breaking down cellulose fibers into nanofibrils, whereas cellulose nanocrystals are typically produced through acid hydrolysis, resulting in shorter, crystalline rod-like particles.

Colloidal stability

Nanocellulose exhibits superior colloidal stability compared to cellulose nanocrystals due to its higher aspect ratio and surface charge heterogeneity, enhancing suspension uniformity in aqueous systems.

Degree of polymerization

Nanocellulose typically exhibits a higher degree of polymerization than cellulose nanocrystals, resulting in greater molecular weight and enhanced mechanical properties.

Reinforcement nanofillers

Nanocellulose and cellulose nanocrystals serve as reinforcement nanofillers with nanocellulose offering higher flexibility and entanglement, while cellulose nanocrystals provide superior stiffness and tensile strength for composite materials.

Nanocellulose vs Cellulose Nanocrystals Infographic

njnir.com

njnir.com