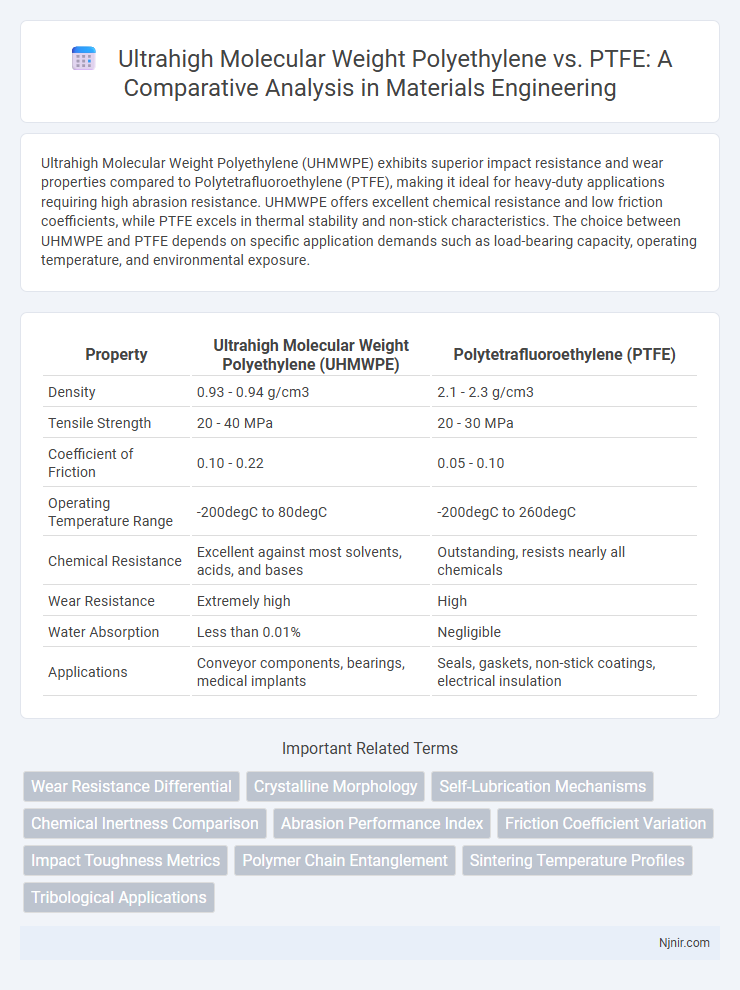

Ultrahigh Molecular Weight Polyethylene (UHMWPE) exhibits superior impact resistance and wear properties compared to Polytetrafluoroethylene (PTFE), making it ideal for heavy-duty applications requiring high abrasion resistance. UHMWPE offers excellent chemical resistance and low friction coefficients, while PTFE excels in thermal stability and non-stick characteristics. The choice between UHMWPE and PTFE depends on specific application demands such as load-bearing capacity, operating temperature, and environmental exposure.

Table of Comparison

| Property | Ultrahigh Molecular Weight Polyethylene (UHMWPE) | Polytetrafluoroethylene (PTFE) |

|---|---|---|

| Density | 0.93 - 0.94 g/cm3 | 2.1 - 2.3 g/cm3 |

| Tensile Strength | 20 - 40 MPa | 20 - 30 MPa |

| Coefficient of Friction | 0.10 - 0.22 | 0.05 - 0.10 |

| Operating Temperature Range | -200degC to 80degC | -200degC to 260degC |

| Chemical Resistance | Excellent against most solvents, acids, and bases | Outstanding, resists nearly all chemicals |

| Wear Resistance | Extremely high | High |

| Water Absorption | Less than 0.01% | Negligible |

| Applications | Conveyor components, bearings, medical implants | Seals, gaskets, non-stick coatings, electrical insulation |

Introduction to Ultrahigh Molecular Weight Polyethylene (UHMWPE) and PTFE

Ultrahigh Molecular Weight Polyethylene (UHMWPE) is a subset of thermoplastic polyethylene characterized by extremely long chains, resulting in a polymer with high impact strength, excellent abrasion resistance, and low coefficient of friction. Polytetrafluoroethylene (PTFE), known for its unique chemical inertness and high heat resistance, is a fluoropolymer widely used in applications requiring non-stick and anti-corrosive properties. Both UHMWPE and PTFE serve critical roles in industrial, medical, and consumer products, with UHMWPE favored for mechanical durability and PTFE valued for its thermal stability and chemical resistance.

Chemical Structure and Molecular Properties

Ultrahigh Molecular Weight Polyethylene (UHMWPE) consists of extremely long chains of ethylene monomers, resulting in high molecular weight and exceptional tensile strength due to extensive chain entanglement. Polytetrafluoroethylene (PTFE) features carbon atoms fully bonded to fluorine atoms, creating a highly stable, chemically inert structure with low surface energy. The molecular properties of UHMWPE emphasize impact resistance and abrasion durability, while PTFE excels in chemical resistance and non-stick performance due to its strong carbon-fluorine bonds.

Mechanical Strength and Durability Comparison

Ultrahigh Molecular Weight Polyethylene (UHMWPE) offers exceptional mechanical strength with a tensile strength ranging from 20 to 40 MPa, surpassing PTFE, which typically has a tensile strength around 21-30 MPa. UHMWPE exhibits superior abrasion resistance and impact strength, making it highly durable under heavy wear and load conditions, whereas PTFE excels in chemical resistance but is more prone to deformation under mechanical stress. The durability of UHMWPE in demanding applications such as industrial bearings and liners is significantly higher compared to PTFE, which is preferred in environments requiring low friction and chemical inertness.

Wear and Abrasion Resistance

Ultrahigh Molecular Weight Polyethylene (UHMWPE) exhibits exceptional wear and abrasion resistance due to its high molecular weight and crystalline structure, making it ideal for applications involving heavy friction and sliding contact. Polytetrafluoroethylene (PTFE) offers low friction and chemical resistance but generally has lower abrasion resistance compared to UHMWPE, resulting in faster wear under harsh mechanical conditions. UHMWPE outperforms PTFE in durability for high-wear environments such as liners, bearings, and conveyor components.

Thermal Stability and Temperature Performance

Ultrahigh Molecular Weight Polyethylene (UHMWPE) exhibits excellent wear resistance but has a lower thermal stability with a maximum service temperature around 80-90degC, limiting its use in high-temperature applications. In contrast, Polytetrafluoroethylene (PTFE) offers superior thermal stability, maintaining performance at temperatures up to 260degC and exhibiting excellent chemical resistance and low friction. PTFE's high melting point and thermal stability make it ideal for applications requiring continuous exposure to elevated temperatures where UHMWPE would degrade.

Chemical Resistance and Environmental Stability

Ultrahigh Molecular Weight Polyethylene (UHMWPE) exhibits excellent chemical resistance against acids, alkalis, and organic solvents, outperforming PTFE in abrasion resistance and impact strength. PTFE offers superior resistance to a broader range of aggressive chemicals, including strong oxidizers and solvents, maintaining stability across extreme temperatures from -200degC to 260degC. Environmental stability of UHMWPE excels in UV resistance and low moisture absorption, while PTFE remains chemically inert and highly resistant to weathering, making both materials ideal for demanding industrial applications.

Friction Coefficients and Lubrication Properties

Ultrahigh Molecular Weight Polyethylene (UHMWPE) exhibits a friction coefficient typically ranging from 0.1 to 0.25, offering excellent self-lubricating properties due to its long polymer chains and high molecular weight, which provide resistance to wear and a smooth sliding surface. Polytetrafluoroethylene (PTFE) demonstrates an even lower friction coefficient, often around 0.05 to 0.10, attributed to its fluorine atoms creating a slippery, non-stick surface that reduces adhesion and friction significantly. Both materials excel in lubrication performance, but PTFE is preferred in applications demanding ultra-low friction, while UHMWPE offers superior impact resistance and durability under heavy loads.

Applications in Materials Engineering

Ultrahigh molecular weight polyethylene (UHMWPE) is prized in materials engineering for its exceptional abrasion resistance, high impact strength, and low friction properties, making it ideal for applications such as conveyor belts, liners, and biomedical implants. Polytetrafluoroethylene (PTFE) excels with its outstanding chemical inertness, high temperature resistance, and low coefficient of friction, widely used in gaskets, seals, and non-stick coatings. UHMWPE is favored for mechanical durability and wear resistance, while PTFE is preferred for chemical resistance and thermal stability in demanding environments.

Processing Methods and Fabrication Techniques

Ultrahigh Molecular Weight Polyethylene (UHMWPE) is primarily processed through compression molding, ram extrusion, and sintering due to its high molecular weight and viscosity, which limit melt flow. PTFE (Polytetrafluoroethylene) undergoes unique paste extrusion, ram extrusion, and sintering processes to achieve its final shape, as it does not melt but decomposes above 327degC. Fabrication techniques for UHMWPE often involve machining of sintered billets or molded parts, while PTFE requires specialized machining or skiving due to its softness and tendency to creep.

Cost Analysis and Sustainability Considerations

Ultrahigh Molecular Weight Polyethylene (UHMWPE) generally costs less than Polytetrafluoroethylene (PTFE), making it a preferred material for budget-sensitive applications requiring high abrasion resistance. UHMWPE exhibits a lower environmental impact due to its energy-efficient production processes and partial recyclability, whereas PTFE's manufacturing involves fluorinated chemicals linked to higher greenhouse gas emissions and complex waste disposal. Evaluating total lifecycle costs, UHMWPE offers advantages in both initial expenditure and sustainability metrics, influencing decisions in industries focused on eco-friendly material selection.

Wear Resistance Differential

Ultrahigh Molecular Weight Polyethylene (UHMWPE) exhibits superior wear resistance compared to PTFE, making it ideal for high-friction applications requiring extended durability.

Crystalline Morphology

Ultrahigh Molecular Weight Polyethylene (UHMWPE) exhibits a highly ordered, lamellar crystalline morphology with large, elongated crystallites enhancing its tensile strength, whereas PTFE (Polytetrafluoroethylene) features a helical-chain crystalline structure with tightly packed orthorhombic unit cells contributing to its exceptional chemical resistance and low friction.

Self-Lubrication Mechanisms

Ultrahigh Molecular Weight Polyethylene exhibits self-lubrication through its high molecular chain entanglement reducing friction, while PTFE's self-lubrication relies on its low surface energy and transfer film formation minimizing wear.

Chemical Inertness Comparison

Ultrahigh Molecular Weight Polyethylene exhibits superior chemical inertness compared to PTFE due to its highly crystalline structure and resistance to strong acids, bases, and solvents under extreme conditions.

Abrasion Performance Index

Ultrahigh Molecular Weight Polyethylene exhibits a superior Abrasion Performance Index compared to PTFE, making it more durable for high-wear applications.

Friction Coefficient Variation

Ultrahigh Molecular Weight Polyethylene exhibits a significantly lower and more stable friction coefficient ranging from 0.05 to 0.15 compared to PTFE's friction coefficient, which varies between 0.04 to 0.10 but tends to increase under higher loads and temperatures.

Impact Toughness Metrics

Ultrahigh Molecular Weight Polyethylene exhibits significantly higher impact toughness, with values up to 250 kJ/m2, compared to PTFE's impact toughness typically below 50 kJ/m2, making UHMWPE more suitable for applications requiring superior impact resistance.

Polymer Chain Entanglement

Ultrahigh Molecular Weight Polyethylene (UHMWPE) exhibits significantly higher polymer chain entanglement compared to PTFE, resulting in superior tensile strength and abrasion resistance.

Sintering Temperature Profiles

Ultrahigh Molecular Weight Polyethylene (UHMWPE) typically sinters between 135-150degC, significantly lower than PTFE, which requires sintering temperatures around 327-342degC to achieve optimal crystallinity and mechanical properties.

Tribological Applications

Ultrahigh Molecular Weight Polyethylene (UHMWPE) offers superior wear resistance and low friction properties compared to PTFE, making it a preferred material in tribological applications requiring high load-bearing capacity and durability.

Ultrahigh Molecular Weight Polyethylene vs PTFE Infographic

njnir.com

njnir.com