Functionally graded materials (FGMs) exhibit continuous variation in composition and properties, enhancing stress distribution and thermal resistance compared to laminated composites, which have discrete interfaces prone to delamination. FGMs offer superior performance in applications requiring smooth transition between different material phases, reducing stress concentration and improving structural integrity. Laminated composites provide design flexibility with tailored stacking sequences but often face challenges in interlaminar shear strength and impact resistance.

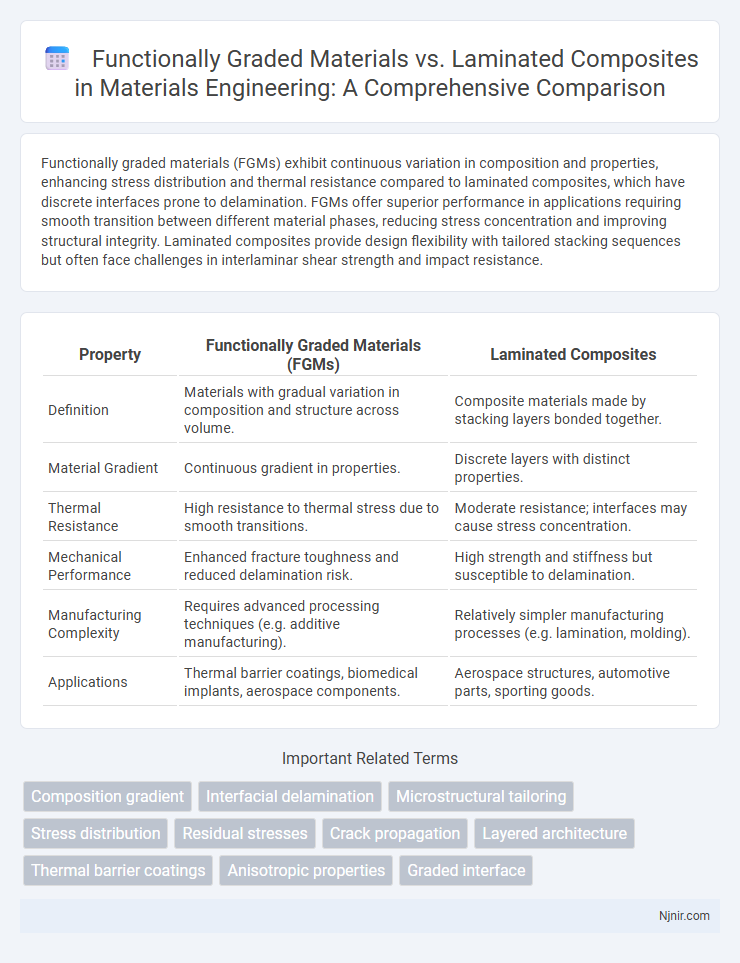

Table of Comparison

| Property | Functionally Graded Materials (FGMs) | Laminated Composites |

|---|---|---|

| Definition | Materials with gradual variation in composition and structure across volume. | Composite materials made by stacking layers bonded together. |

| Material Gradient | Continuous gradient in properties. | Discrete layers with distinct properties. |

| Thermal Resistance | High resistance to thermal stress due to smooth transitions. | Moderate resistance; interfaces may cause stress concentration. |

| Mechanical Performance | Enhanced fracture toughness and reduced delamination risk. | High strength and stiffness but susceptible to delamination. |

| Manufacturing Complexity | Requires advanced processing techniques (e.g. additive manufacturing). | Relatively simpler manufacturing processes (e.g. lamination, molding). |

| Applications | Thermal barrier coatings, biomedical implants, aerospace components. | Aerospace structures, automotive parts, sporting goods. |

Introduction to Advanced Composite Materials

Functionally graded materials (FGMs) exhibit gradual variations in composition and structure, enabling tailored thermal, mechanical, and chemical properties within a single component. Laminated composites consist of multiple bonded layers with distinct fiber orientations, providing enhanced strength and stiffness, particularly in aerospace and automotive applications. Advanced composite materials leverage these design principles to optimize performance by balancing gradation and lamination techniques for specific engineering needs.

Defining Functionally Graded Materials (FGMs)

Functionally graded materials (FGMs) are advanced composites characterized by a gradual variation in composition and structure over volume, designed to achieve specific changes in material properties such as thermal resistance, strength, and stiffness. Unlike laminated composites, which consist of discrete layers bonded together, FGMs exhibit continuous gradients that reduce stress concentrations and improve performance under thermal and mechanical loads. This unique spatial variation in FGMs enables enhanced durability and tailored functionality for applications in aerospace, biomedical implants, and thermal barriers.

Overview of Laminated Composites

Laminated composites consist of multiple bonded layers of materials with varying mechanical properties to achieve enhanced strength, stiffness, and damage tolerance. These composites are engineered by stacking plies with different fiber orientations and matrix materials, optimizing load distribution and resistance to delamination. Their tailored anisotropic behavior and high strength-to-weight ratio make laminated composites essential in aerospace, automotive, and structural applications.

Material Architecture and Microstructure

Functionally graded materials (FGMs) exhibit a continuous variation in composition and microstructure across their volume, resulting in gradual changes in material properties that reduce stress concentrations and enhance performance under thermal or mechanical gradients. Laminated composites consist of discrete layers of different materials stacked together, each layer maintaining distinct microstructural characteristics, which enable tailored directional properties but may introduce interlaminar stresses and potential delamination. The material architecture of FGMs promotes seamless transitions in microstructural phases, whereas laminated composites rely on abrupt interfaces between layers, significantly influencing their mechanical behavior and failure modes.

Manufacturing Techniques and Processes

Functionally graded materials (FGMs) are primarily manufactured using advanced techniques like powder metallurgy, additive manufacturing, and chemical vapor deposition, enabling gradual variation in composition and properties across the volume. Laminated composites typically involve layer-by-layer stacking processes such as hand lay-up, resin transfer molding, or vacuum infusion, which allow precise control over fiber orientation and resin distribution. The continuous gradation in FGMs contrasts with the discrete layering in laminated composites, impacting the selection and complexity of manufacturing processes.

Mechanical Properties Comparison

Functionally graded materials (FGMs) exhibit continuous variation in composition and microstructure, resulting in gradual changes in mechanical properties such as enhanced thermal resistance and improved stress distribution, which reduce stress concentrations compared to laminated composites. Laminated composites consist of stacked layers with distinct interfaces, offering high strength and stiffness but often suffering from delamination and reduced fracture toughness under impact loading. FGMs provide superior fatigue resistance and damage tolerance due to their smooth property gradients, whereas laminated composites excel in tailored directional strength for specific load conditions.

Thermal and Environmental Performance

Functionally graded materials (FGMs) exhibit superior thermal resistance due to their gradual variation in composition, which reduces thermal stresses and improves heat dissipation compared to laminated composites. Laminated composites often suffer from delamination and thermal degradation at interfaces under high temperature and harsh environmental conditions. FGMs outperform laminated composites in environments with cyclic thermal loads and corrosion, providing enhanced durability and reliability in aerospace and automotive applications.

Failure Mechanisms and Damage Tolerance

Functionally graded materials (FGMs) exhibit gradual variations in composition and microstructure, resulting in enhanced stress distribution that reduces the initiation and propagation of cracks compared to laminated composites. Laminated composites, consisting of distinct layers with different material properties, often suffer from interlaminar delamination and matrix cracking under mechanical stress, which significantly compromises their damage tolerance. FGMs provide superior damage tolerance by minimizing stress concentrations and enabling more predictable failure mechanisms through continuous property gradients.

Applications in Industry and Engineering

Functionally graded materials (FGMs) are widely used in aerospace and biomedical engineering for components requiring gradual variation in properties, such as thermal barrier coatings and implants with enhanced biocompatibility. Laminated composites, prevalent in automotive and wind energy sectors, provide superior strength-to-weight ratios and fatigue resistance, essential for structural panels and turbine blades. Both materials optimize performance under specific stress conditions but differ in manufacturing complexity and material gradation control.

Future Trends and Research Directions

Future trends in functionally graded materials (FGMs) emphasize the integration of advanced additive manufacturing techniques and multi-scale modeling to tailor continuous property gradients for aerospace and biomedical applications. Research directions for laminated composites focus on enhancing interlaminar fracture toughness and developing smart materials with embedded sensors for structural health monitoring. Both material types increasingly leverage machine learning algorithms to optimize microstructure designs and predict performance under complex loading conditions.

Composition gradient

Functionally graded materials feature a continuous composition gradient that smoothly transitions material properties, unlike laminated composites which consist of discrete layers with abrupt material changes.

Interfacial delamination

Functionally graded materials exhibit superior resistance to interfacial delamination compared to laminated composites due to their gradual variation in composition and properties, which minimizes stress concentration at interfaces.

Microstructural tailoring

Functionally graded materials achieve microstructural tailoring through continuous variation in composition and properties across the volume, whereas laminated composites exhibit discrete layer-by-layer structural customization to optimize mechanical and thermal performance.

Stress distribution

Functionally graded materials exhibit smooth stress distribution due to gradual variation in material properties, whereas laminated composites experience abrupt stress concentrations at layer interfaces.

Residual stresses

Functionally graded materials exhibit smoother residual stress distributions due to gradual property variation, while laminated composites often experience higher residual stresses at layer interfaces caused by abrupt material changes.

Crack propagation

Functionally graded materials demonstrate superior resistance to crack propagation compared to laminated composites due to their gradual variation in composition and mechanical properties that reduce stress concentration at crack tips.

Layered architecture

Functionally graded materials feature a continuous variation in composition and properties across layers, while laminated composites consist of discrete, distinct layers bonded together with sharp interfaces.

Thermal barrier coatings

Functionally graded materials provide superior thermal barrier coatings by gradually varying composition and properties to reduce thermal stress, unlike laminated composites which struggle with interface delamination under thermal cycles.

Anisotropic properties

Functionally graded materials exhibit continuously varying anisotropic properties across their volume, while laminated composites show distinct anisotropy at the interface of each layer due to discrete material stacking.

Graded interface

Functionally graded materials feature a smooth, continuous variation in composition across the graded interface, enhancing stress distribution and reducing delamination compared to the abrupt property changes at the laminated composite interface.

Functionally graded materials vs Laminated composites Infographic

njnir.com

njnir.com