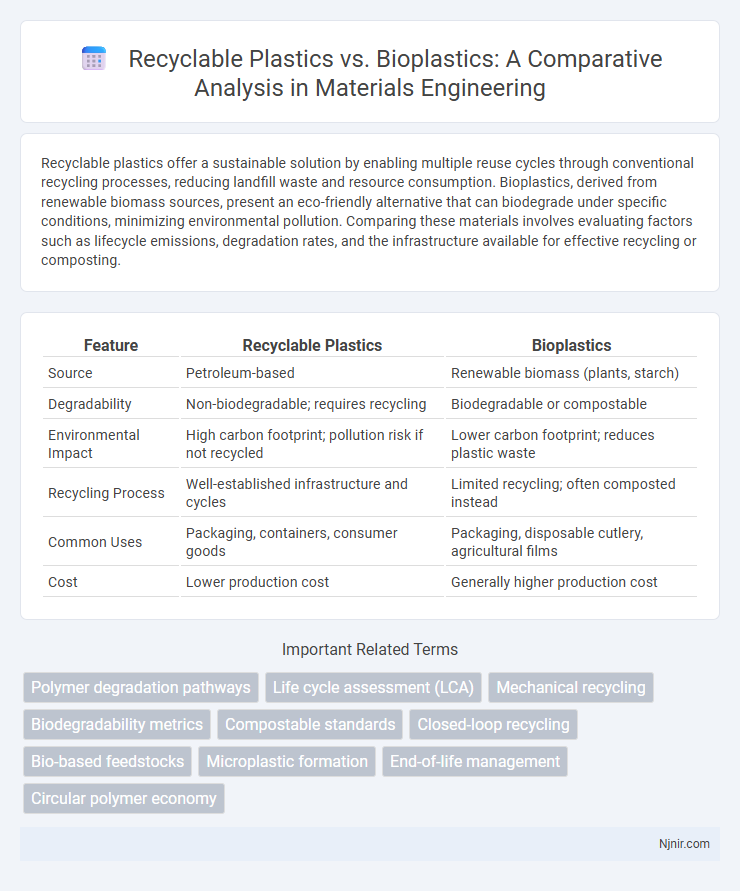

Recyclable plastics offer a sustainable solution by enabling multiple reuse cycles through conventional recycling processes, reducing landfill waste and resource consumption. Bioplastics, derived from renewable biomass sources, present an eco-friendly alternative that can biodegrade under specific conditions, minimizing environmental pollution. Comparing these materials involves evaluating factors such as lifecycle emissions, degradation rates, and the infrastructure available for effective recycling or composting.

Table of Comparison

| Feature | Recyclable Plastics | Bioplastics |

|---|---|---|

| Source | Petroleum-based | Renewable biomass (plants, starch) |

| Degradability | Non-biodegradable; requires recycling | Biodegradable or compostable |

| Environmental Impact | High carbon footprint; pollution risk if not recycled | Lower carbon footprint; reduces plastic waste |

| Recycling Process | Well-established infrastructure and cycles | Limited recycling; often composted instead |

| Common Uses | Packaging, containers, consumer goods | Packaging, disposable cutlery, agricultural films |

| Cost | Lower production cost | Generally higher production cost |

Introduction to Sustainable Plastics

Sustainable plastics include recyclable plastics and bioplastics, both designed to reduce environmental impact by minimizing waste and reliance on fossil fuels. Recyclable plastics are conventional polymers engineered for effective reuse through established recycling systems, while bioplastics are derived from renewable biomass sources such as corn starch or sugarcane, often featuring biodegradability. Choosing between recyclable plastics and bioplastics depends on factors like lifecycle emissions, resource availability, and end-of-life management to promote circular economy principles.

Defining Recyclable Plastics and Bioplastics

Recyclable plastics are synthetic polymers designed for repeated processing and reuse, including common materials such as polyethylene terephthalate (PET) and high-density polyethylene (HDPE). Bioplastics are derived from renewable biomass sources like corn starch or sugarcane and can be biodegradable or designed for specific composting conditions, differentiating them from conventional plastics. Understanding the chemical composition and end-of-life treatment options is essential for optimizing environmental benefits between recyclable plastics and bioplastics.

Material Properties and Performance Comparison

Recyclable plastics such as PET and HDPE offer high durability, excellent chemical resistance, and strong mechanical properties suitable for a wide range of applications. Bioplastics, including PLA and PHA, provide biodegradability and reduced carbon footprint but generally exhibit lower heat resistance and mechanical strength compared to conventional recyclable plastics. The performance gap in tensile strength and thermal stability impacts their suitability for long-term or high-stress uses, making recyclable plastics preferable for durability while bioplastics are favored in eco-friendly, short-lifecycle products.

Environmental Impact Assessment

Recyclable plastics reduce waste by enabling multiple reuse cycles, significantly lowering landfill accumulation and resource extraction compared to single-use plastics. Bioplastics, derived from renewable biomass, offer the advantage of decreased reliance on fossil fuels but may generate higher greenhouse gas emissions during production and require specific composting facilities to degrade efficiently. Environmental impact assessments reveal that while recyclable plastics excel in resource circularity, bioplastics present trade-offs involving land use and end-of-life processing challenges.

End-of-Life Scenarios: Recycling vs Composting

Recyclable plastics, typically polyethylene terephthalate (PET) and high-density polyethylene (HDPE), undergo mechanical recycling processes that convert waste into new plastic products, reducing landfill accumulation and conserving petroleum resources. Bioplastics, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are designed for composting under industrial composting conditions, where microbial activity breaks them down into carbon dioxide, water, and biomass, thereby minimizing environmental persistence. The efficiency of recycling recyclable plastics depends on contamination levels and sorting infrastructure, whereas the successful composting of bioplastics requires controlled temperature, humidity, and time, highlighting distinct end-of-life management strategies for each material type.

Challenges in Collection and Sorting

Recyclable plastics face challenges in collection and sorting due to contamination, mixed polymer types, and limited infrastructure, complicating the recycling process. Bioplastics, often visually indistinguishable from conventional plastics, disrupt sorting systems and can contaminate recycling streams when improperly mixed. Advanced sorting technologies and clear labeling are essential to improve separation accuracy and maintain the integrity of both recyclable plastics and bioplastics in waste management systems.

Industrial Applications and Market Trends

Recyclable plastics dominate industrial applications due to their cost-effectiveness and compatibility with existing recycling infrastructure, making them prevalent in packaging, automotive, and construction sectors. Bioplastics are gaining traction as sustainable alternatives, particularly in food packaging and disposable consumer goods, driven by increasing regulatory pressures and consumer demand for eco-friendly solutions. Market trends indicate a shift toward hybrid materials combining recyclability and biodegradability to meet stringent environmental standards while maintaining industrial performance requirements.

Lifecycle Analysis: Energy and Carbon Footprint

Recyclable plastics generally have a lower carbon footprint during the use phase due to existing recycling infrastructure but often require significant energy for collection, sorting, and reprocessing. Bioplastics, derived from renewable biomass, tend to show reduced greenhouse gas emissions in cultivation and end-of-life biodegradation stages, though energy consumption can be high during feedstock production and processing. Lifecycle analysis reveals that while bioplastics offer potential carbon savings, their overall environmental benefits heavily depend on feedstock type, manufacturing efficiency, and regional recycling capabilities.

Innovations in Polymer Science

Innovations in polymer science have led to the development of advanced recyclable plastics such as polyethylene terephthalate (PET) and high-density polyethylene (HDPE) designed for enhanced recyclability and material recovery. Bioplastics, including polylactic acid (PLA) and polyhydroxyalkanoates (PHA), represent a breakthrough in sustainable materials through their biodegradability and bio-based origins derived from renewable resources like corn starch and microbial fermentation. Cutting-edge research focuses on improving the mechanical properties and degradation rates of bioplastics while optimizing recycling technologies to reduce environmental impact and create circular economies in plastic production.

Future Perspectives in Sustainable Materials Engineering

Recyclable plastics, engineered for multiple reuse cycles, offer efficient waste reduction by maintaining material integrity through advanced sorting and processing technologies. Bioplastics, derived from renewable biomass, present promising carbon-neutral alternatives with evolving formulations aimed at enhanced biodegradability and mechanical performance. Future perspectives in sustainable materials engineering emphasize hybrid approaches combining recyclability and bio-based origins to optimize environmental impact and support circular economy principles.

Polymer degradation pathways

Recyclable plastics primarily degrade through mechanical and chemical recycling processes, whereas bioplastics undergo enzymatic and microbial polymer degradation pathways facilitating biodegradation.

Life cycle assessment (LCA)

Life cycle assessment (LCA) reveals that recyclable plastics generally have lower environmental impacts in resource use and emissions compared to bioplastics, which often involve higher agricultural input and land use but offer benefits in biodegradability and carbon sequestration.

Mechanical recycling

Mechanical recycling of recyclable plastics preserves material integrity by melting and remolding, whereas bioplastics often face challenges in mechanical recycling due to their diverse chemical compositions and biodegradation properties.

Biodegradability metrics

Bioplastics typically exhibit higher biodegradability rates within 6 to 12 months under industrial composting conditions compared to recyclable plastics, which can take several decades to decompose in natural environments.

Compostable standards

Compostable bioplastics adhere to stringent standards like ASTM D6400 and EN 13432, ensuring they break down in industrial composting conditions, unlike many recyclable plastics which require specialized facilities for effective recycling.

Closed-loop recycling

Closed-loop recycling enhances the sustainability of recyclable plastics by continuously reprocessing materials into new products, whereas bioplastics often require specialized composting conditions and may not fully integrate into closed-loop recycling systems.

Bio-based feedstocks

Bio-based feedstocks in bioplastics derive from renewable resources like corn and sugarcane, offering sustainable alternatives to traditional recyclable plastics made from petroleum-based materials.

Microplastic formation

Recyclable plastics often contribute to extensive microplastic formation during degradation, whereas bioplastics tend to break down more fully, reducing microplastic pollution in the environment.

End-of-life management

Recyclable plastics enable multiple reuse cycles through established recycling systems, while bioplastics demand specialized composting facilities or biodegradation processes for effective end-of-life management.

Circular polymer economy

Recyclable plastics and bioplastics both contribute to a circular polymer economy by reducing waste and enabling resource recovery, but recyclable plastics emphasize mechanical or chemical recycling of conventional polymers while bioplastics focus on renewable feedstocks and biodegradability to minimize environmental impact.

Recyclable plastics vs Bioplastics Infographic

njnir.com

njnir.com