Natural fiber composites offer advantages such as biodegradability, low density, and renewability, making them ideal for sustainable materials engineering. Synthetic fiber composites excel in mechanical strength, durability, and resistance to environmental degradation, which supports high-performance applications. Balancing cost, performance, and environmental impact remains crucial in selecting between natural and synthetic fiber composites for advanced material solutions.

Table of Comparison

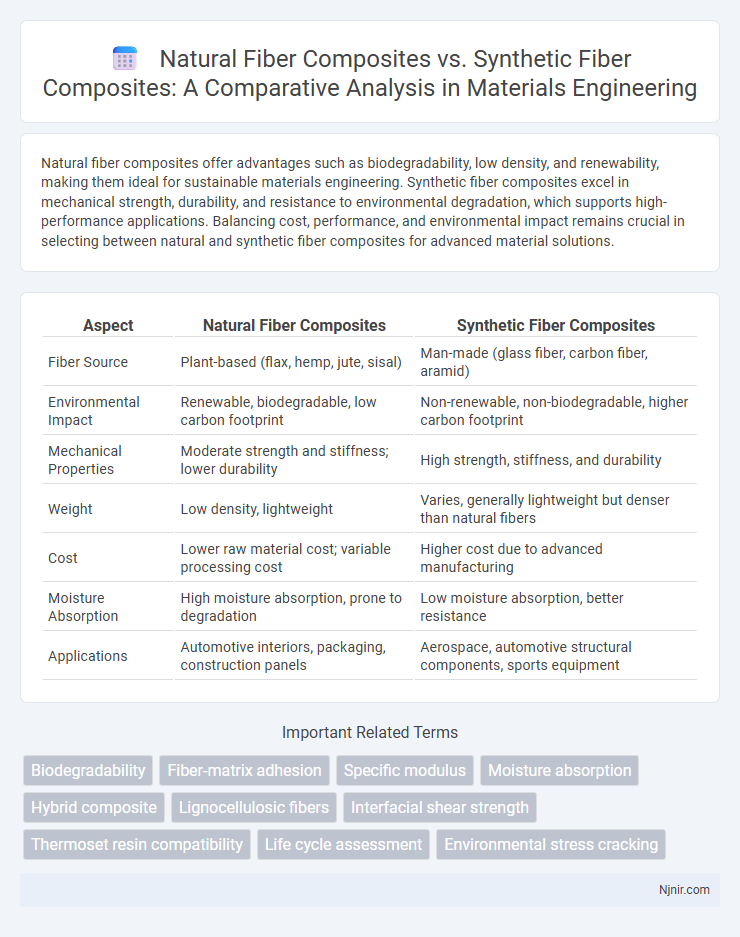

| Aspect | Natural Fiber Composites | Synthetic Fiber Composites |

|---|---|---|

| Fiber Source | Plant-based (flax, hemp, jute, sisal) | Man-made (glass fiber, carbon fiber, aramid) |

| Environmental Impact | Renewable, biodegradable, low carbon footprint | Non-renewable, non-biodegradable, higher carbon footprint |

| Mechanical Properties | Moderate strength and stiffness; lower durability | High strength, stiffness, and durability |

| Weight | Low density, lightweight | Varies, generally lightweight but denser than natural fibers |

| Cost | Lower raw material cost; variable processing cost | Higher cost due to advanced manufacturing |

| Moisture Absorption | High moisture absorption, prone to degradation | Low moisture absorption, better resistance |

| Applications | Automotive interiors, packaging, construction panels | Aerospace, automotive structural components, sports equipment |

Introduction to Fiber Composites

Fiber composites are engineered materials consisting of a fiber reinforcement embedded in a matrix, offering enhanced mechanical properties such as strength, stiffness, and durability. Natural fiber composites utilize fibers derived from renewable resources like hemp, flax, or jute, providing advantages in biodegradability and lightweight characteristics. Synthetic fiber composites, often incorporating glass, carbon, or aramid fibers, deliver superior performance in strength, thermal stability, and resistance to environmental degradation.

Overview of Natural Fiber Composites

Natural fiber composites utilize fibers derived from renewable sources such as flax, hemp, jute, and sisal, offering environmental benefits like biodegradability and reduced carbon footprint. These composites exhibit favorable mechanical properties, including good tensile strength and lightweight characteristics, making them suitable for automotive, construction, and packaging industries. Compared to synthetic fiber composites, natural fiber composites provide cost-effective and sustainable alternatives, though they may face challenges related to moisture absorption and lower durability.

Overview of Synthetic Fiber Composites

Synthetic fiber composites consist of man-made fibers such as glass, carbon, and aramid embedded in polymer matrices, providing superior strength-to-weight ratios and enhanced durability compared to natural fiber composites. These composites offer high resistance to environmental degradation, chemical exposure, and mechanical fatigue, making them ideal for aerospace, automotive, and sports equipment applications. Advances in manufacturing techniques like filament winding and resin transfer molding have further improved the performance and customization of synthetic fiber composites.

Mechanical Properties Comparison

Natural fiber composites exhibit lower tensile strength and modulus compared to synthetic fiber composites such as carbon or glass fibers, yet they offer superior impact resistance and energy absorption due to their inherent toughness and flexibility. Synthetic fiber composites demonstrate higher durability, stiffness, and fatigue resistance, making them ideal for aerospace and automotive applications requiring high mechanical performance. The choice between natural and synthetic fibers hinges on balancing mechanical property requirements with factors like weight, cost, and environmental impact.

Environmental Impact and Sustainability

Natural fiber composites offer significant environmental benefits due to their biodegradability and lower carbon footprint compared to synthetic fiber composites, which rely heavily on non-renewable petroleum-based resources. The production of natural fiber composites consumes less energy and generates fewer emissions, enhancing sustainability in industries such as automotive and construction. However, synthetic composites provide superior durability and weather resistance, presenting a trade-off between long-term environmental impact and performance.

Cost Analysis and Economic Feasibility

Natural fiber composites typically offer lower raw material costs due to renewable sources like hemp, flax, and jute, making them economically attractive for industries aiming to reduce expenses. Synthetic fiber composites such as glass or carbon fibers incur higher material and processing costs, but deliver superior mechanical properties that may justify investment in performance-critical applications. The overall economic feasibility hinges on application requirements, lifecycle costs, environmental regulations, and potential savings from biodegradability and reduced waste disposal in natural fiber composites.

Applications in Industry

Natural fiber composites are increasingly utilized in automotive and construction industries due to their lightweight properties, biodegradability, and cost-effectiveness, making them ideal for interior panels, insulation, and packaging materials. Synthetic fiber composites, such as carbon and glass fiber reinforced polymers, dominate aerospace, sports equipment, and high-performance automotive sectors because of their superior strength, durability, and resistance to environmental factors. The industrial choice between natural and synthetic composites often depends on balancing mechanical performance requirements with environmental impact considerations.

Durability and Lifecycle Performance

Natural fiber composites offer superior biodegradability and lower environmental impact, but often exhibit reduced durability and moisture resistance compared to synthetic fiber composites. Synthetic fiber composites, such as those reinforced with carbon or glass fibers, deliver enhanced tensile strength, fatigue resistance, and longer lifecycle performance under harsh environmental conditions. The choice between the two depends on application requirements balancing sustainability goals with durability and maintenance needs.

Processing Methods and Challenges

Natural fiber composites require processing methods such as alkali treatment, retting, and chemical modification to enhance fiber-matrix adhesion, but face challenges like moisture absorption and variability in fiber quality. Synthetic fiber composites involve techniques like resin transfer molding, pultrusion, and filament winding, offering controlled fiber properties yet facing issues with environmental impact and cost. Both types demand careful processing parameter optimization to balance mechanical performance, durability, and production efficiency.

Future Trends in Fiber Composite Development

Future trends in fiber composite development emphasize sustainability, with natural fiber composites gaining traction due to their biodegradability and lower carbon footprint compared to synthetic fibers like carbon and glass. Advances in hybrid composites are combining natural and synthetic fibers to optimize mechanical properties while reducing environmental impact. Innovations in bio-based resins and recycling technologies are accelerating the adoption of eco-friendly composites in automotive, construction, and aerospace industries.

Biodegradability

Natural fiber composites exhibit superior biodegradability compared to synthetic fiber composites, making them more environmentally sustainable for applications requiring reduced ecological impact.

Fiber-matrix adhesion

Natural fiber composites exhibit superior environmental sustainability but often face challenges with weaker fiber-matrix adhesion compared to synthetic fiber composites, which provide enhanced interfacial bonding and mechanical strength.

Specific modulus

Natural fiber composites offer a higher specific modulus than synthetic fiber composites due to their lower density combined with competitive stiffness.

Moisture absorption

Natural fiber composites absorb significantly more moisture than synthetic fiber composites, impacting their dimensional stability and mechanical properties in high-humidity environments.

Hybrid composite

Hybrid composites combining natural and synthetic fibers optimize mechanical strength, durability, and environmental sustainability for advanced engineering applications.

Lignocellulosic fibers

Lignocellulosic fibers in natural fiber composites offer sustainable, biodegradable, and lightweight alternatives to synthetic fiber composites while providing comparable mechanical strength and reduced environmental impact.

Interfacial shear strength

Natural fiber composites exhibit lower interfacial shear strength compared to synthetic fiber composites due to weaker fiber-matrix adhesion and higher moisture absorption.

Thermoset resin compatibility

Natural fiber composites typically exhibit limited thermoset resin compatibility due to hydrophilic fiber surfaces, whereas synthetic fiber composites offer superior bonding and enhanced mechanical properties with thermoset resins.

Life cycle assessment

Natural fiber composites demonstrate a significantly lower environmental impact throughout their life cycle assessment compared to synthetic fiber composites due to renewable resource use, reduced energy consumption, and improved biodegradability.

Environmental stress cracking

Natural fiber composites exhibit greater resistance to environmental stress cracking compared to synthetic fiber composites due to their biodegradability and better stress distribution under environmental exposure.

Natural Fiber Composites vs Synthetic Fiber Composites Infographic

njnir.com

njnir.com