Thermoplastic composites offer superior impact resistance, recyclability, and faster processing times compared to thermoset composites, making them ideal for industries requiring rapid production and sustainability. Thermoset composites excel in high-temperature stability and excellent chemical resistance due to their cross-linked polymer structure, which provides outstanding mechanical strength for demanding applications. The choice between thermoplastic and thermoset composites depends on specific performance requirements, manufacturing processes, and end-use conditions in materials engineering.

Table of Comparison

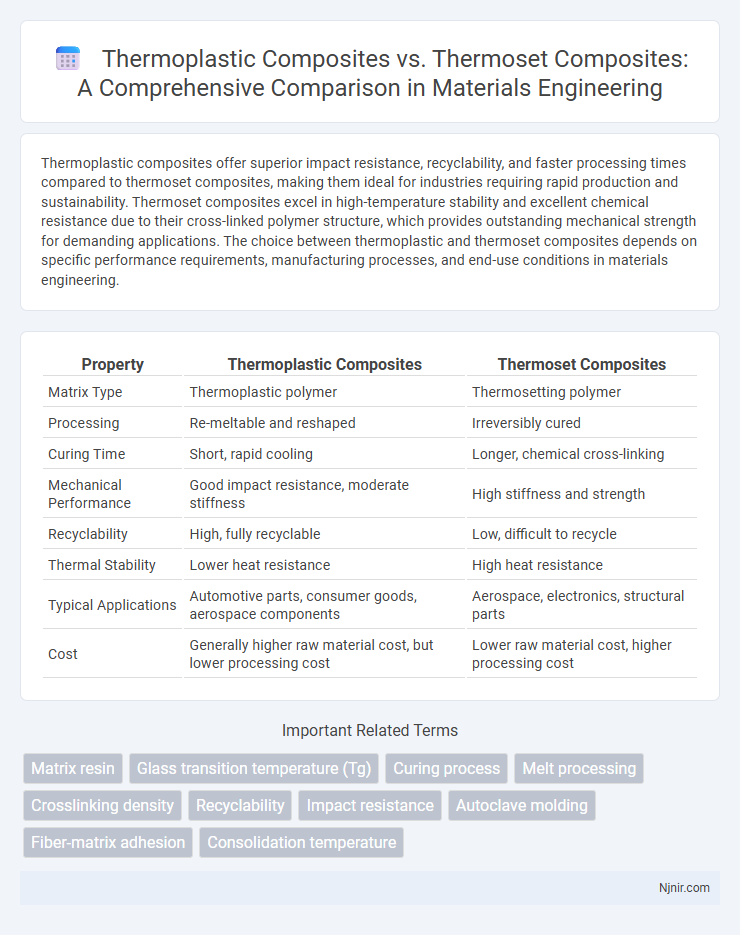

| Property | Thermoplastic Composites | Thermoset Composites |

|---|---|---|

| Matrix Type | Thermoplastic polymer | Thermosetting polymer |

| Processing | Re-meltable and reshaped | Irreversibly cured |

| Curing Time | Short, rapid cooling | Longer, chemical cross-linking |

| Mechanical Performance | Good impact resistance, moderate stiffness | High stiffness and strength |

| Recyclability | High, fully recyclable | Low, difficult to recycle |

| Thermal Stability | Lower heat resistance | High heat resistance |

| Typical Applications | Automotive parts, consumer goods, aerospace components | Aerospace, electronics, structural parts |

| Cost | Generally higher raw material cost, but lower processing cost | Lower raw material cost, higher processing cost |

Introduction to Thermoplastic and Thermoset Composites

Thermoplastic composites consist of reinforcing fibers embedded in a thermoplastic matrix, which softens when heated and solidifies upon cooling, enabling recycling and reshaping. Thermoset composites feature a polymer matrix that undergoes irreversible curing, providing high thermal stability and superior chemical resistance. The selection between thermoplastic and thermoset composites depends on application-specific requirements such as impact resistance, manufacturing speed, and end-of-life recyclability.

Chemical Structure and Polymerization

Thermoplastic composites are composed of linear or branched polymers with no cross-linking, allowing them to soften upon heating and solidify when cooled due to reversible physical changes, which results from polymerization processes like addition or condensation without chemical crosslinking. Thermoset composites consist of heavily cross-linked polymer networks formed through irreversible chemical reactions such as curing or vulcanization, creating a rigid, infusible structure with enhanced thermal stability and mechanical strength. The chemical structure differences between thermoplastics and thermosets directly influence their polymerization mechanisms, thermal behavior, and recyclability in composite applications.

Manufacturing Processes and Techniques

Thermoplastic composites undergo manufacturing processes such as injection molding, thermoforming, and automated fiber placement, enabling faster cycle times and easier recycling compared to thermoset composites, which primarily rely on curing methods like compression molding, resin transfer molding (RTM), and autoclave processing. Thermoplastics soften upon heating, allowing reshaping and welding, whereas thermosets chemically crosslink during curing, resulting in permanent rigidity and higher thermal stability. Advanced techniques like out-of-autoclave curing for thermosets and ultrasonic welding for thermoplastics play crucial roles in optimizing mechanical properties and production efficiency in aerospace and automotive industries.

Mechanical Properties Comparison

Thermoplastic composites exhibit higher impact resistance and improved toughness compared to thermoset composites, making them ideal for applications requiring flexibility and durability under dynamic loads. Thermoset composites generally offer superior thermal stability and higher stiffness due to their rigid cross-linked polymer structure, resulting in enhanced load-bearing capacity and dimensional stability. The fatigue resistance of thermoplastic composites tends to outperform thermosets, providing longer service life in cyclic loading conditions.

Thermal Stability and Performance

Thermoplastic composites exhibit higher thermal stability with melting points typically ranging from 200degC to 300degC, enabling repeated heating cycles without significant degradation, whereas thermoset composites degrade beyond their curing temperature, usually around 150degC to 200degC. Thermoset composites offer superior initial thermal performance due to their rigid, crosslinked polymer networks but lack recyclability and prolonged heat resistance compared to thermoplastics. The enhanced impact resistance and chemical stability of thermoplastic composites make them ideal for applications requiring repeated thermal cycling and long-term durability.

Weight and Density Considerations

Thermoplastic composites generally exhibit lower density compared to thermoset composites, making them advantageous for weight-sensitive applications such as aerospace and automotive industries. The reduced weight in thermoplastic composites contributes to improved fuel efficiency and performance without compromising structural integrity. In contrast, thermoset composites tend to have higher density due to their cross-linked polymer matrices, which enhance stiffness but increase overall weight.

Recycling and Environmental Impact

Thermoplastic composites offer superior recycling potential due to their ability to be reheated and reshaped without significant degradation, enabling efficient material recovery and reuse. Thermoset composites, bound by irreversible cross-linked polymers, pose substantial challenges for recycling and often result in landfill accumulation or energy-intensive disposal methods. The environmental impact of thermoplastic composites is significantly reduced by their recyclability, contributing to lower carbon footprints compared to the persistent waste generated by thermoset composites.

Cost Analysis and Economic Factors

Thermoplastic composites typically incur higher upfront material costs but offer significant savings through faster processing times, recyclability, and reduced labor expenses compared to thermoset composites. Thermoset composites generally involve lower raw material prices but require longer curing cycles and more complex tooling, leading to increased manufacturing costs over large production volumes. Economic factors favor thermoplastic composites in automotive and aerospace industries focused on high-volume, cost-efficient production with sustainability priorities.

Application Areas and Industry Usage

Thermoplastic composites are widely used in aerospace, automotive, and consumer electronics due to their high impact resistance, recyclability, and faster manufacturing cycles. Thermoset composites dominate industries like wind energy, marine, and construction for their superior heat resistance, chemical stability, and structural strength. Both materials serve critical roles, with thermoplastics favored for lightweight, rapid production applications, while thermosets excel in environments demanding longevity and thermal performance.

Future Trends in Composite Materials

Thermoplastic composites exhibit rapid processing speeds, recyclability, and enhanced toughness, making them increasingly attractive for automotive and aerospace advancements. Thermoset composites, known for superior thermal stability and mechanical strength, continue evolving with bio-based resins and improved curing techniques to reduce environmental impact. Future trends emphasize hybrid composites, smart materials integration, and sustainable manufacturing processes to meet stringent performance and ecological standards.

Matrix resin

Thermoplastic composites use matrix resins that are melt-processable and recyclable, offering superior impact resistance and faster curing times compared to thermoset composites, whose cross-linked thermoset resins provide higher thermal stability and chemical resistance but are non-recyclable.

Glass transition temperature (Tg)

Thermoplastic composites exhibit higher glass transition temperatures (Tg) and greater thermal stability compared to thermoset composites, which typically have lower Tg values due to their cross-linked polymer structure.

Curing process

Thermoplastic composites cure through a reversible melting and solidifying process, enabling rapid processing and reshaping, while thermoset composites undergo an irreversible chemical cross-linking reaction during curing that forms a rigid, heat-resistant structure.

Melt processing

Thermoplastic composites enable efficient melt processing through reheating and reshaping of the matrix, whereas thermoset composites undergo irreversible curing, preventing melt-based reshaping after initial hardening.

Crosslinking density

Thermoset composites exhibit high crosslinking density resulting in superior mechanical strength and thermal stability compared to the lower crosslinking density and increased recyclability of thermoplastic composites.

Recyclability

Thermoplastic composites offer superior recyclability compared to thermoset composites due to their ability to be melted and reformed without significant degradation.

Impact resistance

Thermoplastic composites exhibit superior impact resistance compared to thermoset composites due to their higher toughness and ability to absorb energy without brittle fracture.

Autoclave molding

Thermoplastic composites enable faster Autoclave molding cycles and improved recyclability compared to Thermoset composites, which require longer curing times and create more brittle material structures.

Fiber-matrix adhesion

Thermoplastic composites exhibit superior fiber-matrix adhesion due to their ability to melt and re-solidify, creating stronger interfacial bonding compared to the irreversible cross-linked structure of thermoset composites.

Consolidation temperature

Thermoplastic composites require higher consolidation temperatures, typically above 200degC, compared to thermoset composites that cure at lower temperatures around 120-180degC, impacting manufacturing energy efficiency and cycle times.

Thermoplastic composites vs Thermoset composites Infographic

njnir.com

njnir.com