Toughness measures a material's ability to absorb energy and deform plastically without fracturing, which is critical for impact resistance and durability. Hardness quantifies a material's resistance to surface deformation and scratching, often indicating wear resistance but not necessarily strength or toughness. Balancing hardness and toughness is essential in materials engineering to ensure components can withstand mechanical stresses without surface damage or catastrophic failure.

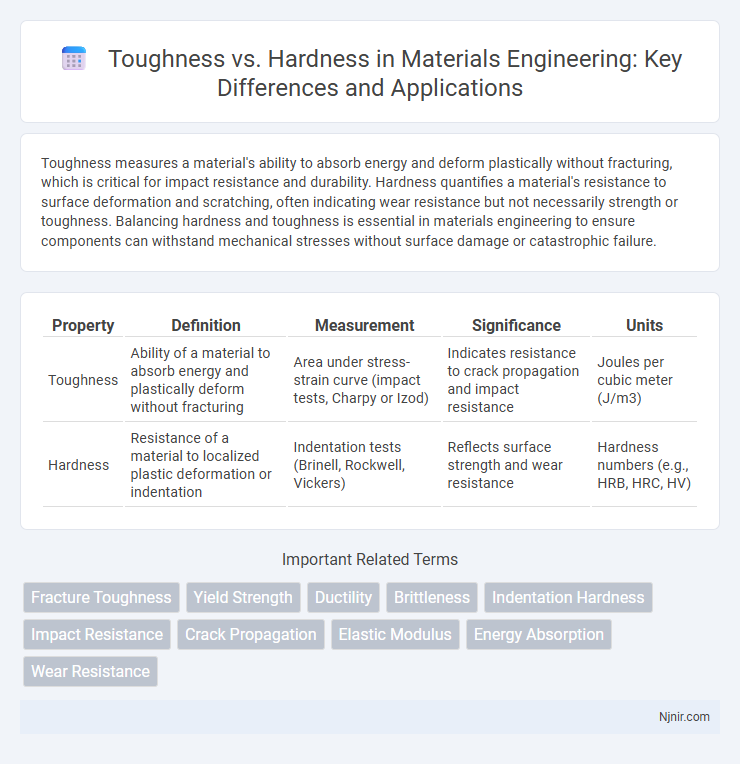

Table of Comparison

| Property | Definition | Measurement | Significance | Units |

|---|---|---|---|---|

| Toughness | Ability of a material to absorb energy and plastically deform without fracturing | Area under stress-strain curve (impact tests, Charpy or Izod) | Indicates resistance to crack propagation and impact resistance | Joules per cubic meter (J/m3) |

| Hardness | Resistance of a material to localized plastic deformation or indentation | Indentation tests (Brinell, Rockwell, Vickers) | Reflects surface strength and wear resistance | Hardness numbers (e.g., HRB, HRC, HV) |

Introduction to Toughness and Hardness

Toughness measures a material's ability to absorb energy and plastically deform without fracturing, highlighting resistance to impact and shock loading. Hardness quantifies a material's resistance to localized surface deformation, such as indentation or scratching, often assessed using scales like Mohs, Rockwell, or Vickers. Understanding both toughness and hardness is crucial for selecting materials in engineering applications requiring durability and wear resistance.

Defining Toughness in Materials Engineering

Toughness in materials engineering refers to a material's ability to absorb energy and deform plastically before fracturing, indicating resistance to brittle failure under impact or stress. It is quantified by the area under the stress-strain curve during tensile testing, combining both strength and ductility properties. Unlike hardness, which measures surface resistance to indentation or scratching, toughness evaluates a material's overall capacity to withstand sudden forces without breaking.

Understanding Hardness in Materials

Hardness in materials refers to their resistance to localized plastic deformation, such as indentation or scratching, commonly measured by tests like Mohs, Rockwell, or Vickers hardness scales. It quantifies a material's ability to withstand surface wear, penetration, or abrasion under applied force, critical for applications requiring durable surfaces. Understanding hardness helps engineers select suitable materials for cutting tools, protective coatings, and structural components.

Key Differences Between Toughness and Hardness

Toughness measures a material's ability to absorb energy and deform plastically before fracturing, indicating resistance to impact and sudden forces. Hardness quantifies surface resistance to indentation, scratching, or abrasion, reflecting durability against wear and deformation. Key differences include toughness as an indicator of overall material strength and impact resistance, while hardness primarily relates to surface strength and scratch resistance.

Testing Methods for Toughness

Toughness testing primarily involves impact tests such as the Charpy and Izod tests, which measure a material's ability to absorb energy and resist fracture under sudden force. These tests use a pendulum to strike a notched specimen, quantifying energy absorbed during breakage to evaluate material toughness effectively. Unlike hardness tests that assess surface resistance to indentation or scratching, toughness tests emphasize the material's capacity to withstand dynamic and shock loading conditions.

Hardness Measurement Techniques

Hardness measurement techniques include methods such as the Brinell, Rockwell, and Vickers tests, each using different indenters and loads to evaluate material resistance to deformation. The Brinell hardness test employs a steel or carbide ball indenter, suitable for materials with coarse structures, while the Rockwell test uses various indenters like steel balls or diamond cones and provides quick, direct hardness values on a dial. Vickers hardness testing uses a diamond pyramid-shaped indenter, allowing precise hardness measurement for thin materials and small parts with micro to macro hardness scales, crucial in assessing material wear resistance and surface strength.

Applications Requiring High Toughness

Materials with high toughness are essential in applications where resistance to impact, shock, and sudden force is critical, such as automotive crash components, aerospace structures, and protective gear. Toughness ensures that materials absorb energy and deform without fracturing, preventing catastrophic failure under dynamic loads. Unlike hardness, which measures surface resistance to deformation, toughness prioritizes durability and ductility for safety-critical applications.

Industries Demanding Superior Hardness

Industries such as aerospace, automotive manufacturing, and heavy machinery demand materials with superior hardness to ensure wear resistance, durability, and extended service life under extreme conditions. Hardness plays a crucial role in tooling, cutting instruments, and surface coatings, where maintaining shape and sharpness is vital for operational efficiency. These sectors prioritize hardness over toughness to prevent deformation and abrasion during high-stress applications.

Relationship Between Toughness and Hardness in Material Selection

Toughness and hardness are critical mechanical properties influencing material selection, where toughness measures a material's ability to absorb energy and deform plastically without fracturing, while hardness quantifies resistance to surface indentation or wear. Materials with high hardness often exhibit lower toughness due to their brittle nature, making them more prone to crack initiation under impact or stress concentration. Balancing toughness and hardness is essential in applications requiring both durability and resistance to deformation, such as cutting tools and structural components, ensuring optimal performance and longevity.

Optimizing Materials: Balancing Toughness and Hardness

Optimizing materials requires balancing toughness and hardness to enhance performance and durability. Hardness measures a material's resistance to deformation or scratching, while toughness indicates its ability to absorb energy and withstand impact without fracturing. Engineering applications prioritize tailored compositions and heat treatments to achieve an ideal combination, ensuring both strength and resilience in demanding environments.

Fracture Toughness

Fracture toughness measures a material's ability to resist crack propagation under stress, making it a crucial indicator of toughness unlike hardness, which quantifies resistance to surface indentation.

Yield Strength

Yield strength measures a material's resistance to permanent deformation, distinguishing toughness by indicating how much stress it can withstand before yielding, while hardness primarily reflects surface resistance to indentation or scratching.

Ductility

Toughness measures a material's ability to absorb energy and deform plastically without fracturing, emphasizing high ductility, while hardness assesses resistance to surface deformation.

Brittleness

Toughness measures a material's ability to absorb energy and deform plastically without fracturing, whereas hardness indicates resistance to surface indentation, with brittleness reflecting a material's tendency to fracture without significant deformation when subjected to stress.

Indentation Hardness

Indentation hardness measures a material's resistance to localized plastic deformation, providing critical insights into its mechanical properties distinct from toughness, which evaluates energy absorption before fracture.

Impact Resistance

Toughness measures a material's ability to absorb energy and resist impact without fracturing, while hardness primarily indicates surface resistance to indentation and wear.

Crack Propagation

Toughness measures a material's ability to absorb energy and resist crack propagation, while hardness primarily evaluates surface resistance to deformation without directly indicating crack growth behavior.

Elastic Modulus

Toughness measures a material's ability to absorb energy before fracturing, whereas hardness indicates resistance to surface deformation, with elastic modulus quantifying stiffness and influencing both properties by determining a material's elastic response to stress.

Energy Absorption

Toughness measures a material's ability to absorb energy and deform plastically without fracturing, while hardness quantifies resistance to localized surface deformation or indentation.

Wear Resistance

Wear resistance depends more on hardness, as harder materials better withstand surface abrasion compared to tougher materials.

Toughness vs Hardness Infographic

njnir.com

njnir.com