Cold spray technology preserves the microstructure and mechanical properties of feedstock powders by depositing particles at lower temperatures, minimizing oxidation and thermal degradation. In contrast, thermal spray processes involve melting feedstock materials, which can alter phase composition and introduce tensile stresses due to rapid cooling. The choice between cold spray and thermal spray hinges on application requirements for coating density, adhesion strength, and thermal sensitivity of the substrate material.

Table of Comparison

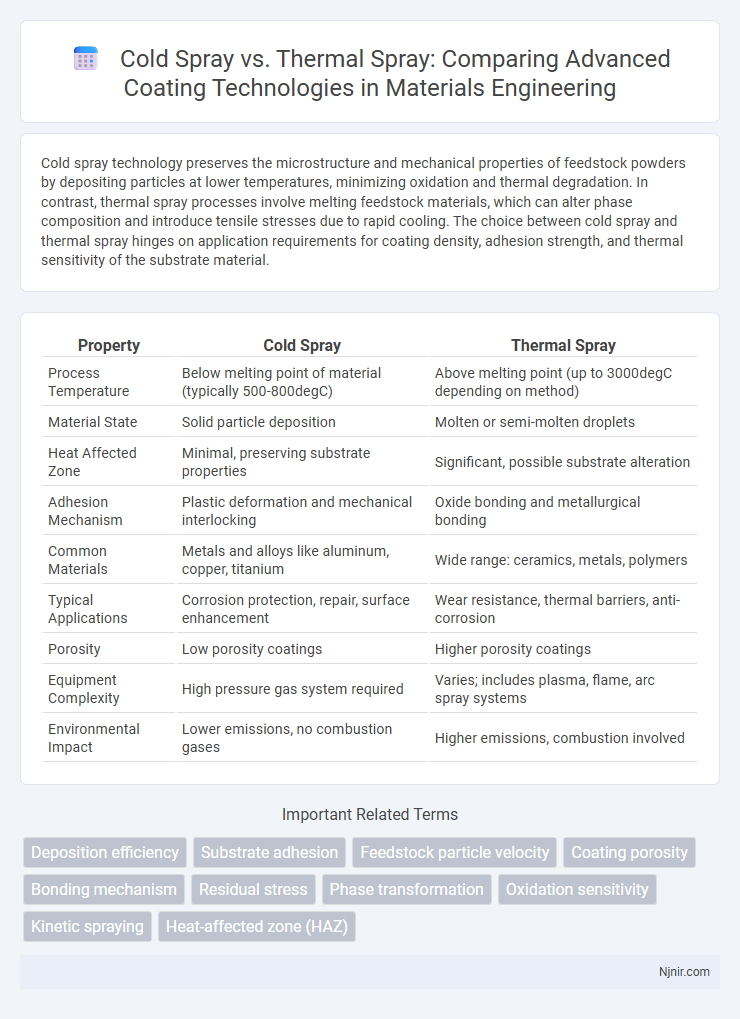

| Property | Cold Spray | Thermal Spray |

|---|---|---|

| Process Temperature | Below melting point of material (typically 500-800degC) | Above melting point (up to 3000degC depending on method) |

| Material State | Solid particle deposition | Molten or semi-molten droplets |

| Heat Affected Zone | Minimal, preserving substrate properties | Significant, possible substrate alteration |

| Adhesion Mechanism | Plastic deformation and mechanical interlocking | Oxide bonding and metallurgical bonding |

| Common Materials | Metals and alloys like aluminum, copper, titanium | Wide range: ceramics, metals, polymers |

| Typical Applications | Corrosion protection, repair, surface enhancement | Wear resistance, thermal barriers, anti-corrosion |

| Porosity | Low porosity coatings | Higher porosity coatings |

| Equipment Complexity | High pressure gas system required | Varies; includes plasma, flame, arc spray systems |

| Environmental Impact | Lower emissions, no combustion gases | Higher emissions, combustion involved |

Introduction to Thermal Spray and Cold Spray Technologies

Thermal spray technology involves melting materials and propelling them onto surfaces to form coatings, utilizing processes like plasma spraying, flame spraying, and arc spraying to achieve high-temperature bonding and enhanced surface properties. Cold spray technology, by contrast, accelerates powder particles at supersonic speeds without melting them, creating coatings through plastic deformation and mechanical interlocking, retaining original material properties and minimizing oxidation. Both techniques offer distinct advantages in coatings applications, with thermal spray excelling in high-temperature, wear-resistant layers and cold spray favored for impact-resistant, low-heat coatings.

Fundamental Principles of Cold Spray

Cold spray technology relies on accelerating solid powder particles to supersonic speeds using a high-pressure gas stream, allowing them to impact and bond with the substrate without melting. Unlike thermal spray, which typically involves melting the feedstock material to create a coating, cold spray operates below the melting point, preserving the powder's microstructure and minimizing oxidation. This solid-state deposition process results in dense, high-strength coatings with low residual stress and excellent adhesion.

Overview of Thermal Spray Processes

Thermal spray processes include various techniques such as plasma spraying, flame spraying, and high-velocity oxygen fuel (HVOF) spraying, each utilizing heat to melt coating materials for surface protection or enhancement. Cold spray differs as it propels solid particles at high velocity without melting, preserving material properties and reducing oxidation. Thermal spray coatings are widely used for wear resistance, corrosion protection, and thermal barriers in aerospace, automotive, and industrial applications.

Key Material Compatibility: Cold Spray vs Thermal Spray

Cold spray technology uses high-velocity kinetic energy to deposit powdered metals, making it highly compatible with temperature-sensitive materials like aluminum, titanium, and polymers due to minimal heat exposure. Thermal spray processes, such as plasma or flame spraying, involve melting the feedstock, which allows coatings on heat-resistant substrates such as steel, ceramics, and refractory metals but may cause thermal distortion or oxidation on sensitive materials. Selecting between cold spray and thermal spray depends on substrate thermal sensitivity, desired coating properties, and material compatibility to prevent degradation or loss of mechanical integrity.

Process Parameters and Equipment Comparison

Cold spray employs high-velocity gas to accelerate powder particles below their melting point, preserving original material properties, whereas thermal spray uses high-temperature sources like plasma or combustion to melt powders before deposition. Process parameters in cold spray include gas temperature (typically 300-800degC), gas pressure (up to 6 MPa), and particle velocity (500-1200 m/s), contrasting with thermal spray's higher temperatures (up to 15,000degC) and generally lower particle velocities (50-200 m/s). Equipment for cold spray features compressed gas systems, high-pressure nozzles, and low-thermal impact setups, while thermal spray devices require plasma torches, combustion burners, or arc guns capable of sustaining extreme temperatures for melting feedstock.

Coating Microstructure and Adhesion Differences

Cold spray coating produces a dense, low-oxidation microstructure with minimal thermal degradation, enhancing substrate integrity and adhesion strength through high-velocity particle impact. Thermal spray coatings often exhibit a lamellar structure with oxide inclusions and higher porosity due to elevated temperature processing, which can reduce bonding strength and increase the likelihood of microcracks. Adhesion in cold spray is primarily mechanical interlocking complemented by metallurgical bonding, whereas thermal spray relies on mechanical anchoring and often requires post-treatment to improve coating cohesion.

Mechanical Properties of Deposited Layers

Cold spray deposits exhibit superior mechanical properties such as higher hardness, improved tensile strength, and enhanced wear resistance due to minimal oxidation and retained particle integrity during deposition. Thermal spray coatings often suffer from oxidation and phase transformation, leading to reduced bonding strength and increased porosity. Consequently, cold spray layers demonstrate better adhesion and fatigue resistance compared to thermal spray coatings, making them preferable for high-performance mechanical applications.

Applications in Aerospace, Automotive, and Energy Sectors

Cold spray technology enables high-velocity deposition of metal coatings without melting, making it ideal for aerospace components requiring corrosion resistance and repair without microstructural changes. Thermal spray processes, involving molten particles, are widely used in automotive industries for wear-resistant coatings on engine parts and exhaust systems to enhance durability and thermal barriers. In the energy sector, cold spray is preferred for repairing turbine blades and pipelines, while thermal spray coatings provide thermal insulation and protection against oxidation in boilers and gas turbines.

Environmental Impact and Safety Considerations

Cold spray technology produces minimal airborne pollutants and uses no combustion, significantly reducing environmental impact compared to thermal spray, which often emits hazardous gases and particulates. The absence of high temperatures in cold spray enhances operator safety by eliminating risks associated with burns, toxic fumes, and fire hazards commonly linked to thermal spray processes. Cold spray also generates less waste and requires fewer safety precautions, making it a more eco-friendly and safer option for industrial coating applications.

Future Trends and Technological Innovations

Cold spray technology is advancing with enhanced particle velocity control and novel nozzle designs, enabling superior coating adhesion and reduced substrate heating compared to traditional thermal spray methods. Integration of real-time monitoring and AI-driven process optimization is driving higher precision and consistency in cold spray applications across aerospace and medical industries. Future trends emphasize hybrid systems combining cold and thermal spray techniques to tailor coating properties, improve efficiency, and expand material compatibility for next-generation manufacturing.

Deposition efficiency

Cold spray offers significantly higher deposition efficiency than thermal spray by minimizing material oxidation and thermal degradation during the coating process.

Substrate adhesion

Cold spray provides superior substrate adhesion by depositing particles at lower temperatures, preventing thermal damage and oxidation, unlike thermal spray which relies on high heat that can weaken bonding strength.

Feedstock particle velocity

Cold spray achieves higher feedstock particle velocity, often exceeding 500 m/s, compared to thermal spray processes that typically range between 50-300 m/s, resulting in denser and stronger coatings.

Coating porosity

Cold spray coatings typically exhibit lower porosity levels than thermal spray coatings due to their solid-state deposition process, resulting in denser and more durable protective layers.

Bonding mechanism

Cold spray forms bonds through high-velocity particle impact causing plastic deformation and mechanical interlocking, while thermal spray relies on molten or semi-molten particles that solidify upon contact to create metallurgical or mechanical bonds.

Residual stress

Cold spray produces significantly lower residual stress compared to thermal spray due to its low-temperature deposition process that minimizes thermal contraction and distortion.

Phase transformation

Cold spray preserves initial material microstructure by avoiding phase transformation, while thermal spray induces phase changes due to high-temperature exposure.

Oxidation sensitivity

Cold spray significantly reduces oxidation sensitivity compared to thermal spray by depositing particles at lower temperatures, minimizing oxidation during the coating process.

Kinetic spraying

Kinetic spraying, a cold spray technique, propels metal particles at supersonic speeds to create dense coatings without melting, offering superior bonding and minimal oxidation compared to traditional thermal spray methods.

Heat-affected zone (HAZ)

Cold spray minimizes the heat-affected zone (HAZ) by depositing materials at low temperatures, whereas thermal spray generates a significant HAZ due to high-temperature processes.

cold spray vs thermal spray Infographic

njnir.com

njnir.com