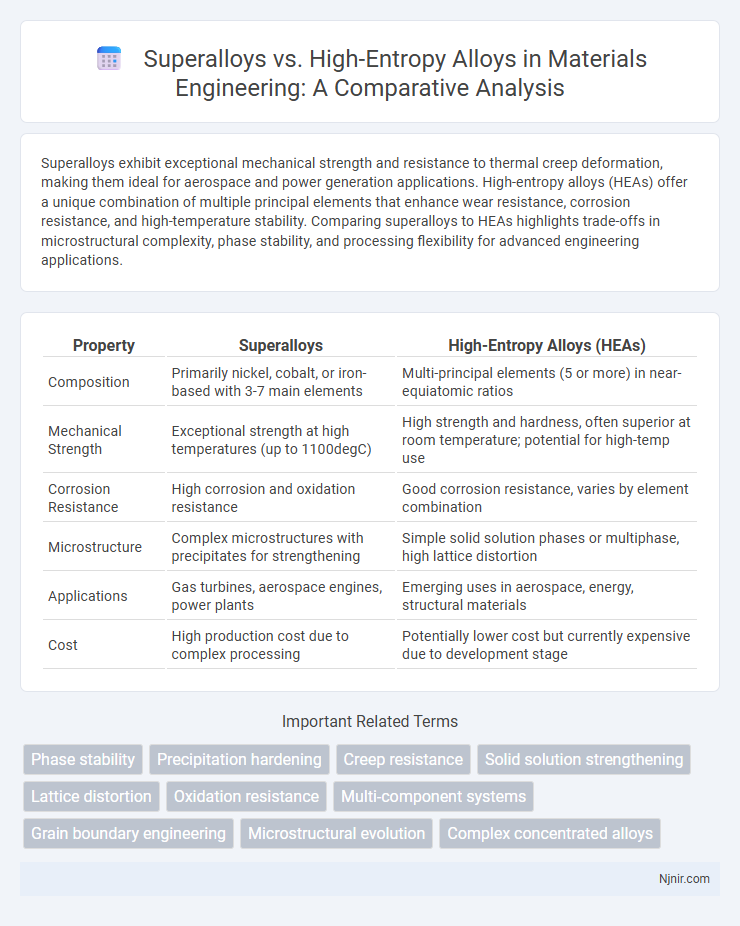

Superalloys exhibit exceptional mechanical strength and resistance to thermal creep deformation, making them ideal for aerospace and power generation applications. High-entropy alloys (HEAs) offer a unique combination of multiple principal elements that enhance wear resistance, corrosion resistance, and high-temperature stability. Comparing superalloys to HEAs highlights trade-offs in microstructural complexity, phase stability, and processing flexibility for advanced engineering applications.

Table of Comparison

| Property | Superalloys | High-Entropy Alloys (HEAs) |

|---|---|---|

| Composition | Primarily nickel, cobalt, or iron-based with 3-7 main elements | Multi-principal elements (5 or more) in near-equiatomic ratios |

| Mechanical Strength | Exceptional strength at high temperatures (up to 1100degC) | High strength and hardness, often superior at room temperature; potential for high-temp use |

| Corrosion Resistance | High corrosion and oxidation resistance | Good corrosion resistance, varies by element combination |

| Microstructure | Complex microstructures with precipitates for strengthening | Simple solid solution phases or multiphase, high lattice distortion |

| Applications | Gas turbines, aerospace engines, power plants | Emerging uses in aerospace, energy, structural materials |

| Cost | High production cost due to complex processing | Potentially lower cost but currently expensive due to development stage |

Introduction to Superalloys and High-Entropy Alloys

Superalloys are advanced metallic materials known for exceptional mechanical strength, resistance to thermal creep deformation, and oxidation resistance at high temperatures, often used in aerospace and power generation industries. High-entropy alloys (HEAs) consist of multiple principal elements in near-equiatomic ratios, resulting in unique microstructures and enhanced properties such as high strength, corrosion resistance, and thermal stability. Both materials represent cutting-edge developments in metallurgy, with superalloys optimized for high-temperature performance and HEAs offering novel compositional flexibility and enhanced mechanical behavior.

Historical Development of Advanced Alloys

Superalloys originated in the mid-20th century, primarily developed for high-temperature applications in jet engines and gas turbines, characterized by nickel, cobalt, or iron bases with complex alloying elements like chromium and aluminum to enhance corrosion and heat resistance. High-entropy alloys (HEAs), a more recent innovation from the early 2000s, emerged as a novel class of materials containing multiple principal elements mixed in near-equiatomic proportions, aiming to achieve superior mechanical properties and phase stability through high configurational entropy. The historical evolution from superalloys to HEAs reflects advancements in materials science prioritizing enhanced performance under extreme conditions, driven by the need for improved strength, oxidation resistance, and thermal stability in aerospace and energy sectors.

Chemical Composition: Superalloys vs High-Entropy Alloys

Superalloys typically consist of a base metal such as nickel, cobalt, or iron combined with elements like chromium, aluminum, titanium, and molybdenum to enhance strength and corrosion resistance. High-entropy alloys (HEAs) are characterized by their equiatomic or near-equiatomic proportions of five or more principal elements, often including combinations of transition metals such as Fe, Ni, Co, Cr, and Mn, resulting in unique mechanical and thermal properties. The multicomponent nature of HEAs promotes high configurational entropy, stabilizing solid solution phases, whereas superalloys rely on carefully balanced alloying for phase stability and performance at elevated temperatures.

Microstructure and Phase Stability

Superalloys exhibit a well-defined microstructure with a gamma matrix reinforced by gamma-prime precipitates, ensuring excellent phase stability at high temperatures. High-entropy alloys (HEAs) feature complex, multi-element compositions resulting in simple solid-solution phases with outstanding phase stability due to their high configurational entropy. The microstructural stability of HEAs often surpasses traditional superalloys under extreme conditions, making them promising candidates for advanced high-temperature applications.

Mechanical Properties Comparison

Superalloys exhibit exceptional mechanical properties such as high strength, creep resistance, and fatigue life at elevated temperatures, primarily due to their well-established nickel, cobalt, or iron-based matrices. High-entropy alloys (HEAs), composed of multiple principal elements in near-equal proportions, offer superior hardness, wear resistance, and excellent fatigue strength, deriving from their complex microstructures and lattice distortion effects. Comparative studies indicate that while superalloys outperform HEAs in long-term high-temperature stability, HEAs demonstrate enhanced room-temperature yield strength and toughness, suggesting complementary applications in advanced engineering fields.

High-Temperature Performance and Oxidation Resistance

High-entropy alloys (HEAs) demonstrate superior high-temperature performance compared to traditional superalloys due to their unique multicomponent microstructures, which enhance phase stability and creep resistance above 900degC. HEAs also exhibit exceptional oxidation resistance attributed to the formation of stable, protective oxide layers such as alumina or chromia, which mitigate surface degradation during prolonged exposure to aggressive environments. In contrast, superalloys, while optimized for high-temperature strength and oxidation resistance through nickel-based compositions, often face limitations in thermal stability and oxidation protection at extreme temperatures beyond 1000degC.

Processing Techniques and Manufacturing Challenges

Superalloys typically undergo conventional processing techniques such as casting, forging, and powder metallurgy, with challenges including grain boundary strengthening and controlling segregation during solidification. High-entropy alloys require advanced processing methods like rapid solidification, mechanical alloying, and additive manufacturing to achieve homogenous microstructures and phase stability. Manufacturing challenges for high-entropy alloys involve managing complex multi-element diffusion behaviors and preventing brittle intermetallic phase formation, which are less critical in traditional superalloy production.

Applications in Aerospace, Energy, and Beyond

Superalloys excel in aerospace and energy sectors due to their exceptional high-temperature strength and corrosion resistance, making them ideal for turbine blades and jet engines. High-entropy alloys (HEAs) offer innovative properties such as enhanced wear resistance and thermal stability, expanding their use in next-generation aerospace components and energy storage systems. Both materials push boundaries in critical applications, with superalloys dominating traditional roles and HEAs emerging as promising materials for future high-performance environments.

Sustainability and Resource Considerations

Superalloys typically rely on critical elements such as nickel, cobalt, and chromium, raising concerns about resource scarcity and environmental impact due to intensive mining and refining processes. High-entropy alloys (HEAs) offer potential sustainability advantages by utilizing more abundant and diverse elemental compositions, potentially reducing reliance on critical raw materials and enhancing recyclability. The development of HEAs focuses on optimizing performance while minimizing ecological footprints, aligning with growing industry demands for sustainable materials in aerospace and energy sectors.

Future Trends and Research Directions

Future trends in superalloys focus on enhancing high-temperature strength and oxidation resistance through nano-structuring and alloying with refractory elements, while high-entropy alloys (HEAs) research prioritizes developing novel compositions to achieve superior mechanical properties and thermal stability across diverse environments. Emerging studies explore combining high-entropy concepts with traditional superalloy matrices to create hybrid materials with optimized phase stability and creep resistance for aerospace and power generation applications. Advances in computational alloy design and additive manufacturing accelerate the discovery of tailored superalloys and HEAs with improved microstructural control and performance under extreme conditions.

Phase stability

Superalloys exhibit phase stability through well-defined precipitate strengthening phases like g' and g'', whereas high-entropy alloys gain phase stability from the high configurational entropy that promotes single-phase solid solutions.

Precipitation hardening

Superalloys exhibit exceptional precipitation hardening due to gamma prime (g') phase formation, while high-entropy alloys achieve enhanced strength through complex multi-element precipitates offering superior thermal stability.

Creep resistance

Superalloys exhibit superior creep resistance at high temperatures due to their well-optimized gamma prime precipitates, while high-entropy alloys show promising but less mature creep resistance attributed to their complex multi-element microstructures.

Solid solution strengthening

Superalloys achieve solid solution strengthening primarily through the addition of elements like nickel, cobalt, and chromium to form a stable matrix, while high-entropy alloys rely on multiple principal elements in near-equal concentrations to create severe lattice distortion and enhanced solid solution strengthening.

Lattice distortion

High-entropy alloys exhibit significantly greater lattice distortion than conventional superalloys, enhancing their mechanical strength and thermal stability at elevated temperatures.

Oxidation resistance

Superalloys exhibit excellent oxidation resistance at high temperatures due to their protective oxide layers, whereas high-entropy alloys offer enhanced oxidation resistance through complex multi-element compositions that form stable, adherent oxide films.

Multi-component systems

Multi-component high-entropy alloys feature multiple principal elements in near-equiatomic proportions, enhancing phase stability and mechanical properties compared to traditional superalloys with predominant base metals.

Grain boundary engineering

Grain boundary engineering in superalloys enhances creep resistance and high-temperature stability by optimizing grain boundary character distribution, while high-entropy alloys leverage complex multi-element compositions to form stable, high-angle grain boundaries that improve mechanical strength and corrosion resistance.

Microstructural evolution

Superalloys exhibit microstructural evolution dominated by gamma prime precipitation and phase stability under high-temperature creep conditions, whereas high-entropy alloys display complex multi-principal element-induced lattice distortion that stabilizes single-phase solid solutions and enhances resistance to microstructural degradation.

Complex concentrated alloys

Complex concentrated alloys, including superalloys and high-entropy alloys, exhibit enhanced mechanical properties and corrosion resistance due to their multi-principal element compositions that promote unique microstructures and phase stability.

Superalloys vs High-entropy alloys Infographic

njnir.com

njnir.com