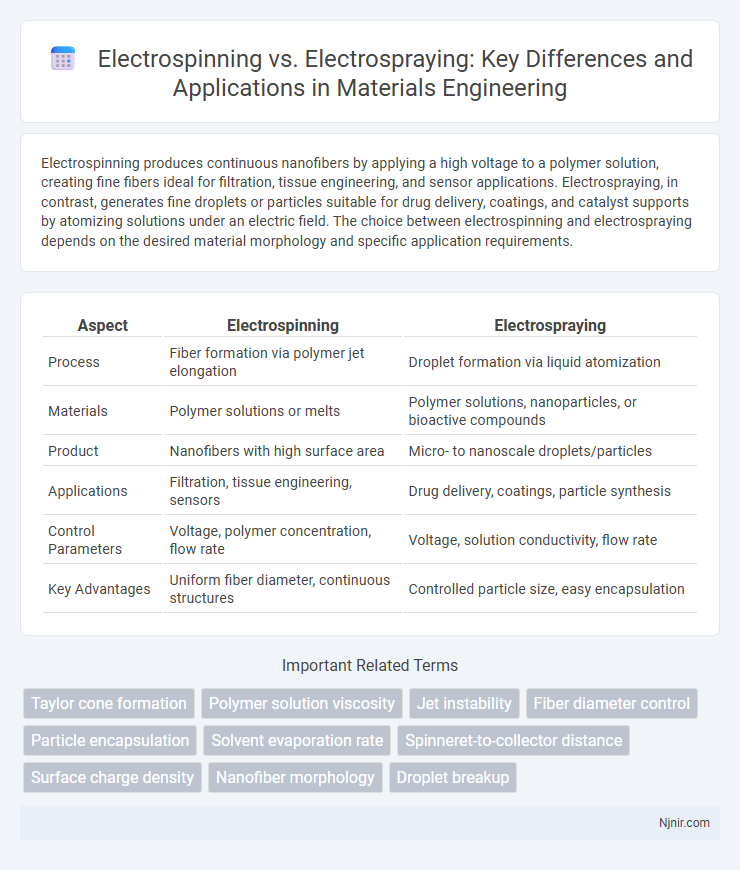

Electrospinning produces continuous nanofibers by applying a high voltage to a polymer solution, creating fine fibers ideal for filtration, tissue engineering, and sensor applications. Electrospraying, in contrast, generates fine droplets or particles suitable for drug delivery, coatings, and catalyst supports by atomizing solutions under an electric field. The choice between electrospinning and electrospraying depends on the desired material morphology and specific application requirements.

Table of Comparison

| Aspect | Electrospinning | Electrospraying |

|---|---|---|

| Process | Fiber formation via polymer jet elongation | Droplet formation via liquid atomization |

| Materials | Polymer solutions or melts | Polymer solutions, nanoparticles, or bioactive compounds |

| Product | Nanofibers with high surface area | Micro- to nanoscale droplets/particles |

| Applications | Filtration, tissue engineering, sensors | Drug delivery, coatings, particle synthesis |

| Control Parameters | Voltage, polymer concentration, flow rate | Voltage, solution conductivity, flow rate |

| Key Advantages | Uniform fiber diameter, continuous structures | Controlled particle size, easy encapsulation |

Introduction to Electrospinning and Electrospraying

Electrospinning is a technique that produces continuous nanofibers by applying a high voltage to a polymer solution, resulting in ultrafine fiber formation with applications in tissue engineering and filtration. Electrospraying, on the other hand, generates fine droplets from a liquid under an electric field, primarily used for coating, drug delivery, and material deposition. Both methods employ electrostatic forces but differ in their output morphology--fibers versus particles--enabling tailored functional materials for various industries.

Principles and Mechanisms of Electrospinning

Electrospinning uses high voltage electric fields to create continuous nanofibers from polymer solutions or melts by stretching a charged jet, driven by electrostatic repulsion and surface tension forces. This process involves the formation of a Taylor cone at the needle tip, followed by elongation and whipping instability leading to ultrathin fiber deposition on a grounded collector. In contrast, electrospraying produces fine droplets instead of fibers by breaking the liquid jet into charged particles due to dominant Rayleigh instability, useful for particle coating and encapsulation applications.

Principles and Mechanisms of Electrospraying

Electrospraying operates by applying a high-voltage electric field to a liquid, forming a charged jet that breaks into fine droplets due to electrostatic repulsion and surface tension forces. Unlike electrospinning, which produces continuous polymeric fibers through viscoelastic jet elongation, electrospraying generates micron to nanometer-sized particles by atomizing the liquid into discrete droplets. The key mechanisms in electrospraying involve cone-jet formation, Coulomb fission, and solvent evaporation, leading to dried particles collected on a substrate.

Key Differences Between Electrospinning and Electrospraying

Electrospinning produces continuous nanofibers by applying a high-voltage electric field to a polymer solution, whereas electrospraying generates fine droplets or particles through atomization of the same solution. The primary distinction lies in the material's morphology: electrospinning forms fibrous mats with interconnected fibers suitable for filtration and tissue engineering, while electrospraying yields particulate structures ideal for drug delivery and coatings. Process parameters such as solution viscosity and electric field strength determine whether fibers or particles are formed, influencing the final application and material properties.

Material Selection and Processing Parameters

Electrospinning primarily utilizes polymer solutions or melts to produce continuous nanofibers, whereas electrospraying employs low-viscosity liquids for the formation of nanoparticles or droplets. Material selection in electrospinning depends on polymer molecular weight, viscosity, and solvent volatility, while electrospraying focuses on solution conductivity, surface tension, and dielectric properties. Processing parameters such as applied voltage, flow rate, and tip-to-collector distance are critical in both techniques, with electrospinning requiring higher viscosity and controlled solvent evaporation to maintain fiber morphology, contrasted by electrospraying that optimizes droplet size through lower viscosity and higher conductivity.

Morphological Characteristics of Resulting Structures

Electrospinning produces continuous nanofibers with uniform diameters and a high surface area-to-volume ratio, leading to porous mats ideal for filtration and tissue engineering. Electrospraying generates discrete particles or droplets ranging from nanometers to micrometers, resulting in non-fibrous structures with controllable size and surface morphology. The choice between electrospinning and electrospraying directly affects the morphology, influencing applications based on fiber continuity or particle formation.

Applications in Materials Engineering

Electrospinning produces continuous nanofibers ideal for applications in tissue engineering scaffolds, filtration membranes, and composite reinforcement due to their high surface area and porosity. Electrospraying generates nanoparticles and microparticles suited for drug delivery systems, coating technologies, and catalyst supports by enabling precise particle size control and uniform dispersion. Both techniques leverage electrostatic forces but differ in fiber formation versus particle generation, influencing their respective roles in advanced materials engineering.

Advantages and Limitations of Each Technique

Electrospinning offers the advantage of producing continuous nanofibers with high surface area-to-volume ratios, ideal for applications in tissue engineering, filtration, and drug delivery, but it faces limitations such as scalability challenges and sensitivity to environmental conditions. Electrospraying excels in generating uniform micro- and nanoparticles suitable for coatings, encapsulation, and targeted drug delivery, although it struggles with controlling particle size distribution and often produces lower throughput compared to electrospinning. Both techniques require precise control of parameters like voltage, solution properties, and flow rate to optimize morphology and functionality, impacting their efficiency and applicability across industries.

Recent Advances and Innovations

Recent advances in electrospinning and electrospraying have focused on enhancing control over fiber and particle morphology through innovative nozzle designs and tailored polymer solutions. Innovations such as coaxial and triaxial electrospinning facilitate the production of multi-layered nanofibers with improved mechanical and functional properties for biomedical and filtration applications. Electrospraying advancements include the development of hybrid systems that enable precise encapsulation and targeted drug delivery, leveraging nanostructured particle formation with enhanced surface area and controlled release profiles.

Future Perspectives in Electrospinning and Electrospraying

Future perspectives in electrospinning emphasize advancements in nanofiber functionalization and scalable production techniques to enhance biomedical and energy applications. Electrospraying developments focus on precise particle size control and targeted drug delivery systems through improved nozzle designs and real-time monitoring. Integration of both techniques with artificial intelligence and automation is expected to revolutionize material fabrication, enabling customizable and efficient manufacturing processes.

Taylor cone formation

Electrospinning produces a stable Taylor cone leading to continuous fiber jets, while electrospraying forms less stable Taylor cones that generate discrete droplets.

Polymer solution viscosity

Electrospinning requires a higher polymer solution viscosity to form continuous fibers, whereas electrospraying operates effectively at lower viscosities, producing fine droplets instead of fibers.

Jet instability

Jet instability in electrospinning produces continuous nanofibers by elongating charged polymer jets, whereas in electrospraying, greater jet instability leads to droplet formation for nanoparticle generation.

Fiber diameter control

Electrospinning achieves precise fiber diameter control ranging from nanometers to micrometers by adjusting solution viscosity, voltage, and flow rate, whereas electrospraying primarily produces droplets with less control over fiber diameter due to its focus on particle formation.

Particle encapsulation

Electrospinning produces nanofibers ideal for sustained release, while electrospraying creates microparticles and nanoparticles offering efficient particle encapsulation for targeted drug delivery systems.

Solvent evaporation rate

Electrospinning typically requires a slower solvent evaporation rate to form continuous nanofibers, whereas electrospraying demands a faster solvent evaporation rate to produce fine, discrete droplets.

Spinneret-to-collector distance

Electrospinning typically requires a longer spinneret-to-collector distance of 10-20 cm to allow fiber elongation and solvent evaporation, whereas electrospraying uses a shorter distance of 5-10 cm to facilitate droplet formation and minimize particle agglomeration.

Surface charge density

Electrospinning generates fibers with higher surface charge density compared to electrospraying, resulting in enhanced fiber alignment and deposition control.

Nanofiber morphology

Electrospinning produces continuous nanofibers with uniform morphology, while electrospraying generates nanoparticles or microdroplets with irregular shapes and less defined structures.

Droplet breakup

Electrospinning produces continuous polymer nanofibers by elongating a charged jet without droplet breakup, while electrospraying generates fine droplets through the breakup of a charged liquid jet into smaller droplets due to Rayleigh instability.

electrospinning vs electrospraying Infographic

njnir.com

njnir.com