Shape memory alloys exhibit the ability to return to a predetermined shape after deformation when exposed to specific temperatures due to a phase transformation between martensite and austenite. Superelastic alloys demonstrate exceptional elasticity at constant temperatures, recovering large strains immediately upon unloading through stress-induced phase changes. These distinct properties make shape memory alloys ideal for temperature-responsive applications, while superelastic alloys are preferred for dynamic, high-strain environments.

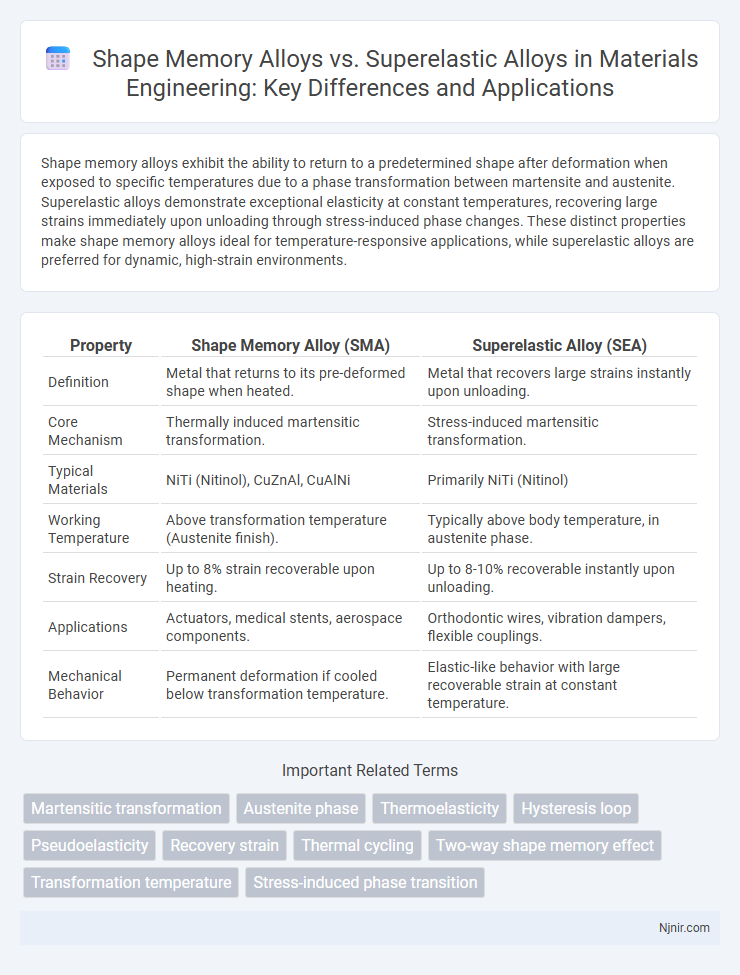

Table of Comparison

| Property | Shape Memory Alloy (SMA) | Superelastic Alloy (SEA) |

|---|---|---|

| Definition | Metal that returns to its pre-deformed shape when heated. | Metal that recovers large strains instantly upon unloading. |

| Core Mechanism | Thermally induced martensitic transformation. | Stress-induced martensitic transformation. |

| Typical Materials | NiTi (Nitinol), CuZnAl, CuAlNi | Primarily NiTi (Nitinol) |

| Working Temperature | Above transformation temperature (Austenite finish). | Typically above body temperature, in austenite phase. |

| Strain Recovery | Up to 8% strain recoverable upon heating. | Up to 8-10% recoverable instantly upon unloading. |

| Applications | Actuators, medical stents, aerospace components. | Orthodontic wires, vibration dampers, flexible couplings. |

| Mechanical Behavior | Permanent deformation if cooled below transformation temperature. | Elastic-like behavior with large recoverable strain at constant temperature. |

Introduction to Shape Memory and Superelastic Alloys

Shape memory alloys (SMAs) exhibit the unique ability to return to their original shape after deformation when exposed to specific temperature changes, due to a reversible martensitic phase transformation. Superelastic alloys, a subset of SMAs, display extraordinary elasticity at temperatures above their transformation range, enabling large strains to be recovered immediately upon unloading without permanent deformation. Key materials such as nickel-titanium (NiTi) dominate this field because of their robust shape memory effect and superior superelastic properties, making them essential in biomedical devices, aerospace, and robotics.

Fundamental Mechanisms: Shape Memory Effect vs Superelasticity

Shape memory alloys (SMAs) exhibit the shape memory effect through a reversible martensitic phase transformation, allowing the material to return to a predetermined shape upon heating after deformation in the martensitic phase. Superelastic alloys, a subset of SMAs, display superelasticity by undergoing stress-induced martensitic transformation at a constant temperature above the austenite finish temperature, enabling large elastic strains that recover upon unloading. The fundamental mechanism difference lies in temperature-driven phase changes for shape memory effects versus stress-driven reversible phase transformations for superelastic behavior.

Chemical Composition and Phase Transformation

Shape memory alloys (SMAs) typically consist of nickel-titanium (NiTi) with precise stoichiometric ratios near equiatomic composition, enabling martensitic phase transformation from austenite to martensite under temperature changes. Superelastic alloys, often of the same NiTi composition, exhibit stress-induced phase transformation, where mechanical loading triggers reversible austenite-martensite conversion at temperatures above the transformation range. The chemical composition directly influences the transformation temperatures (Ms, Mf, As, Af) and the material's ability to undergo fully recoverable strain through either thermal or mechanical phase changes.

Microstructural Characteristics and Changes

Shape memory alloys (SMAs) exhibit microstructural changes primarily through a reversible martensitic transformation between austenite and martensite phases, enabling the shape memory effect. Superelastic alloys undergo stress-induced martensitic transformation at temperatures above the austenite finish temperature, allowing large recoverable strains without permanent deformation. The key microstructural difference lies in the thermally versus stress-driven phase transitions that govern their functional properties.

Mechanical Properties Comparison

Shape memory alloys exhibit high recoverable strain up to 8%, enabling permanent deformation recovery through phase transformation, while superelastic alloys demonstrate exceptional elasticity with recoverable strains around 6-8% under mechanical loading. Superelastic alloys have superior fatigue resistance and can endure millions of cycles without permanent deformation, unlike shape memory alloys which may experience functional fatigue over time. Mechanical strength in superelastic alloys is typically higher, with enhanced hysteresis behavior, making them ideal for applications requiring repetitive load resilience.

Applications in Engineering and Medicine

Shape memory alloys (SMAs) are widely used in engineering for actuators, sensors, and vibration dampers due to their ability to return to a pre-defined shape when heated. In medicine, SMAs find applications in stents, orthodontic archwires, and surgical tools, leveraging their biocompatibility and shape recovery properties. Superelastic alloys excel in applications requiring large, reversible strains such as eyeglass frames and flexible medical devices, offering superior deformation resistance without permanent damage.

Processing and Fabrication Techniques

Shape memory alloys (SMAs) are typically processed through vacuum induction melting followed by hot rolling and solution annealing to achieve a uniform microstructure essential for their phase transformation properties. Superelastic alloys require precise thermomechanical treatments such as cold working and aging to stabilize the austenitic phase, enhancing their reversible strain capacity. Advanced fabrication techniques like additive manufacturing and laser surface treatment are increasingly employed to refine microstructures and improve functional performance in both SMA and superelastic materials.

Performance under Thermal and Mechanical Loading

Shape memory alloys exhibit excellent thermal responsiveness by returning to their original shape upon heating due to phase transformation between martensite and austenite, demonstrating superior performance in thermal cycling applications. Superelastic alloys maintain high mechanical flexibility under stress at a constant temperature, showing remarkable strain recovery capacity without permanent deformation, ideal for dynamic mechanical loading. Both materials excel in different loading conditions: shape memory alloys optimize thermal actuation while superelastic alloys provide robustness in mechanical resilience.

Advantages and Limitations of Each Alloy

Shape memory alloys (SMAs) exhibit the unique ability to return to their original shape after deformation due to a reversible phase transformation, offering advantages in applications requiring precise actuation and vibration damping but can be limited by slower response times and sensitivity to temperature changes. Superelastic alloys provide exceptional elasticity and large reversible strains at constant temperatures, making them ideal for applications needing high flexibility and energy absorption, though they may suffer from lower fatigue life and potential stress relaxation under cyclic loading. Both alloys play critical roles in biomedical devices and aerospace engineering, with selection dependent on specific mechanical and thermal performance requirements.

Future Trends and Research Directions

Future trends in shape memory alloy (SMA) research emphasize enhancing fatigue resistance and expanding biomedical applications through nanoscale alloy engineering. Superelastic alloys are being developed with improved hysteresis behavior and temperature range adaptability to support aerospace and robotics advancements. Emerging research explores hybrid materials combining SMA and superelastic properties for multifunctional smart devices and integrated sensing technologies.

Martensitic transformation

Shape memory alloys undergo a reversible martensitic transformation enabling shape recovery upon heating, while superelastic alloys exhibit stress-induced martensitic transformation allowing for large, recoverable strains at constant temperature.

Austenite phase

Austenite phase in shape memory alloys exhibits stable, high-temperature crystallinity enabling reversible martensitic transformation, whereas in superelastic alloys it facilitates stress-induced transformation for enhanced elasticity.

Thermoelasticity

Shape memory alloys exhibit thermoelasticity through reversible phase transformations driven by temperature changes, while superelastic alloys demonstrate thermoelasticity via stress-induced phase transformations that recover upon unloading.

Hysteresis loop

Shape memory alloys exhibit a wider hysteresis loop indicating larger energy dissipation during phase transformation compared to superelastic alloys, which display a narrower hysteresis loop reflecting more reversible and efficient mechanical behavior.

Pseudoelasticity

Shape memory alloys exhibit pseudoelasticity by undergoing reversible strain through stress-induced phase transformations, enabling large recoverable deformations without permanent shape change.

Recovery strain

Shape memory alloys exhibit a typical recovery strain of up to 8%, while superelastic alloys can achieve recovery strains exceeding 10% through stress-induced phase transformations.

Thermal cycling

Shape memory alloys exhibit phase transformation and recover their original shape upon heating through thermal cycling, whereas superelastic alloys demonstrate reversible deformation and recover shape instantly without heating due to stress-induced martensitic transformation.

Two-way shape memory effect

Two-way shape memory effect is exhibited by shape memory alloys through reversible transformation between martensite and austenite phases, while superelastic alloys primarily demonstrate one-way strain recovery under mechanical stress without spontaneous shape change upon unloading.

Transformation temperature

Shape memory alloys exhibit transformation temperatures typically ranging from -50degC to 100degC, while superelastic alloys have transformation temperatures below room temperature, enabling their reversible deformation at ambient conditions.

Stress-induced phase transition

Shape memory alloys exhibit stress-induced phase transitions that allow permanent deformation recovery, while superelastic alloys undergo reversible stress-induced phase transitions enabling large elastic strains without permanent shape change.

shape memory alloy vs superelastic alloy Infographic

njnir.com

njnir.com