Self-healing polymers enhance material durability by autonomously repairing internal damage through reversible chemical bonds, improving longevity and mechanical performance. Self-assembled monolayers (SAMs) provide precise surface modification at the molecular level, enabling tailored interface properties such as corrosion resistance and biocompatibility. Comparing these advanced materials highlights self-healing polymers' dynamic restoration capabilities versus SAMs' static but highly controlled surface functionalities, both crucial for innovative materials engineering applications.

Table of Comparison

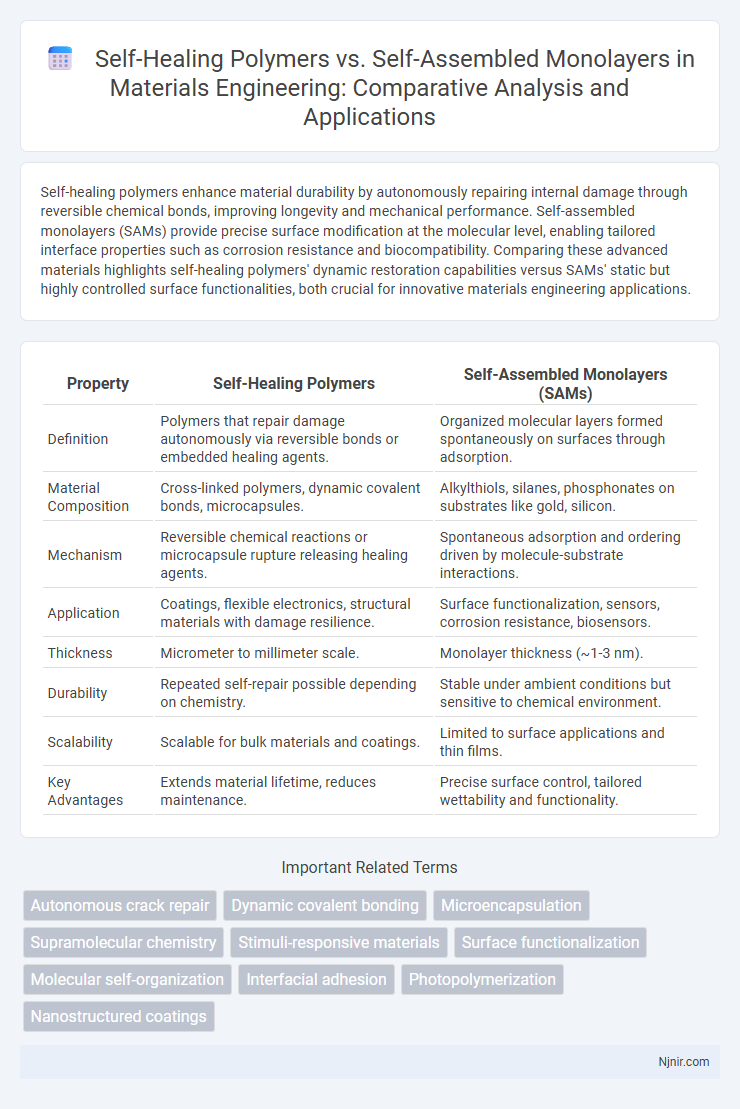

| Property | Self-Healing Polymers | Self-Assembled Monolayers (SAMs) |

|---|---|---|

| Definition | Polymers that repair damage autonomously via reversible bonds or embedded healing agents. | Organized molecular layers formed spontaneously on surfaces through adsorption. |

| Material Composition | Cross-linked polymers, dynamic covalent bonds, microcapsules. | Alkylthiols, silanes, phosphonates on substrates like gold, silicon. |

| Mechanism | Reversible chemical reactions or microcapsule rupture releasing healing agents. | Spontaneous adsorption and ordering driven by molecule-substrate interactions. |

| Application | Coatings, flexible electronics, structural materials with damage resilience. | Surface functionalization, sensors, corrosion resistance, biosensors. |

| Thickness | Micrometer to millimeter scale. | Monolayer thickness (~1-3 nm). |

| Durability | Repeated self-repair possible depending on chemistry. | Stable under ambient conditions but sensitive to chemical environment. |

| Scalability | Scalable for bulk materials and coatings. | Limited to surface applications and thin films. |

| Key Advantages | Extends material lifetime, reduces maintenance. | Precise surface control, tailored wettability and functionality. |

Introduction to Smart Materials in Materials Engineering

Self-healing polymers and self-assembled monolayers represent two pivotal innovations in smart materials within materials engineering, enhancing durability and functionality through inherent adaptive properties. Self-healing polymers autonomously repair damages, extending the lifespan of structural composites and coatings by restoring mechanical integrity after deformation or fracture. Self-assembled monolayers form organized molecular layers on surfaces, enabling precise tuning of surface properties such as wettability, biocompatibility, and corrosion resistance, critical for advanced sensor development and nanoengineering applications.

Fundamentals of Self-Healing Polymers

Self-healing polymers are advanced materials designed to automatically repair damage without external intervention, relying on intrinsic or extrinsic healing mechanisms such as reversible covalent bonds, hydrogen bonding, or microcapsule embedding. These polymers restore mechanical integrity and extend lifespan by re-forming molecular interactions or releasing healing agents upon fracture. Unlike self-assembled monolayers, which are thin, ordered molecular coatings formed through adsorption on surfaces primarily for modifying interfacial properties, self-healing polymers emphasize bulk material recovery and structural resilience.

Mechanisms Behind Self-Assembled Monolayers

Self-assembled monolayers (SAMs) form through the spontaneous organization of molecules on a substrate driven by specific interactions such as covalent bonding, van der Waals forces, and hydrogen bonding, resulting in a highly ordered, densely packed molecular layer. Unlike self-healing polymers, which rely on reversible covalent bonds or supramolecular interactions to repair damage, SAMs achieve structural integrity through the precise molecular arrangement and strong affinity between the head groups and the surface atoms, typically metals like gold or silicon. This molecular self-organization enables tunable surface properties, including wettability, corrosion resistance, and biocompatibility, making SAMs crucial in nanoscale surface engineering and sensor technology.

Comparative Structural Properties

Self-healing polymers exhibit dynamic covalent bonds or supramolecular interactions that enable autonomous repair through reversible cross-linking, offering bulk material recovery. Self-assembled monolayers (SAMs) consist of organized, single-molecule-thick layers formed via chemisorption on substrates, providing precise control over surface chemistry and molecular orientation. The key structural contrast lies in the three-dimensional network enabling mechanical resilience in self-healing polymers versus the two-dimensional, highly ordered, and tunable interfacial architecture characteristic of SAMs.

Healing and Assembly Processes: A Technical Overview

Self-healing polymers utilize dynamic covalent bonds or reversible physical interactions to autonomously repair damage through polymer chain reformation, enabling restoration of mechanical properties without external intervention. Self-assembled monolayers (SAMs) form via spontaneous adsorption and organization of organic molecules on substrate surfaces, driven by chemisorption and van der Waals interactions, creating highly ordered, single-molecule-thick films. While self-healing polymers focus on intrinsic material recovery through molecular mobility and reversible bonding, SAMs rely on precise molecular assembly mechanisms for surface functionalization and interface control.

Applications in Coatings and Surface Protection

Self-healing polymers in coatings enable autonomous repair of microcracks, enhancing durability and lifespan in automotive and aerospace industries. Self-assembled monolayers (SAMs) provide molecular-level surface functionalization, offering corrosion resistance and reduced friction on metal and semiconductor surfaces. Combining self-healing polymers with SAMs improves protective coatings by integrating dynamic repair with tailored surface properties for advanced material performance.

Mechanical Performance and Durability

Self-healing polymers exhibit enhanced mechanical performance by autonomously repairing damage, significantly extending durability in applications such as coatings and flexible electronics. In contrast, self-assembled monolayers (SAMs) primarily improve surface properties like corrosion resistance and adhesion, but their mechanical strength is limited by their nanometer-scale thickness. Consequently, self-healing polymers offer superior longevity under mechanical stress, while SAMs serve as protective interfaces enhancing surface durability without bulk mechanical reinforcement.

Environmental Stability and Responsiveness

Self-healing polymers exhibit superior environmental stability through intrinsic repair mechanisms that restore material integrity after damage, maintaining performance under varying environmental conditions. In contrast, self-assembled monolayers (SAMs) rely on non-covalent interactions that provide molecular-level responsiveness but result in limited durability and susceptibility to environmental degradation such as oxidation or desorption. The dynamic adaptability of self-healing polymers enables sustained functionality in harsh environments, while SAMs offer precise surface modifications with fast responsiveness but require controlled conditions for long-term stability.

Challenges and Limitations in Material Integration

Self-healing polymers face challenges in achieving consistent healing efficiency and mechanical strength over multiple damage cycles, often struggling with limited environmental stability and slow healing rates. Self-assembled monolayers encounter difficulties in maintaining uniform coverage and robust adhesion on diverse substrates, which limits their scalability and long-term durability in practical applications. Both materials require advanced integration techniques to overcome issues related to interface compatibility, processing conditions, and functional performance under operational stresses.

Future Prospects and Research Directions

Self-healing polymers offer promising advancements in autonomous material repair, enhancing durability and sustainability in coatings, electronics, and biomedical applications, whereas self-assembled monolayers (SAMs) advance nanoscale surface functionalization for sensors and molecular electronics. Future research in self-healing polymers focuses on improving healing efficiency, mechanical strength, and environmental responsiveness using stimuli-responsive and bio-inspired chemistries. Exploration of hybrid systems integrating self-healing polymers with SAMs aims to create multifunctional materials with enhanced self-repair and tunable surface properties for smart technological applications.

Autonomous crack repair

Self-healing polymers enable autonomous crack repair through intrinsic material properties that restore structural integrity, whereas self-assembled monolayers primarily modify surface chemistry without providing inherent crack repair capabilities.

Dynamic covalent bonding

Self-healing polymers utilize dynamic covalent bonding to enable reversible network formation for material repair, whereas self-assembled monolayers rely on non-covalent interactions and stable covalent anchoring without dynamic bond exchange.

Microencapsulation

Self-healing polymers utilize microencapsulation to contain healing agents that autonomously repair material damage, whereas self-assembled monolayers rely on molecular organization without microencapsulation for surface modification.

Supramolecular chemistry

Self-healing polymers utilize dynamic covalent bonds and non-covalent supramolecular interactions for autonomous repair, whereas self-assembled monolayers rely on precise supramolecular organization at interfaces to form ordered molecular coatings.

Stimuli-responsive materials

Self-healing polymers autonomously repair damage through dynamic covalent bonds or reversible interactions, while self-assembled monolayers provide stimuli-responsive surfaces by reorganizing molecular structures in response to environmental changes.

Surface functionalization

Self-healing polymers offer dynamic surface functionalization through reversible chemical bonds enabling repair, while self-assembled monolayers provide precise, stable molecular surface modification via organized single-layer formation.

Molecular self-organization

Self-healing polymers leverage dynamic covalent bonds and supramolecular interactions for autonomous molecular self-organization and repair, while self-assembled monolayers rely on spontaneous, thermodynamically driven molecular self-organization on surfaces to form ordered nanoscale structures.

Interfacial adhesion

Self-healing polymers improve interfacial adhesion through dynamic bond reformation, while self-assembled monolayers enhance adhesion by creating organized, chemically tailored surface interfaces.

Photopolymerization

Photopolymerization in self-healing polymers enables rapid damage repair through light-triggered crosslinking, whereas in self-assembled monolayers it facilitates precise surface functionalization by initiating polymer growth on substrates.

Nanostructured coatings

Self-healing polymers offer dynamic repair capabilities in nanostructured coatings, whereas self-assembled monolayers provide precise molecular ordering and surface functionalization essential for nanoscale coating stability and performance.

Self-healing polymers vs Self-assembled monolayers Infographic

njnir.com

njnir.com