Functionally graded materials (FGMs) exhibit a gradual variation in composition and structure over volume, enhancing performance by minimizing stress concentrations and improving thermal resistance. Composite materials combine distinct phases or constituents to achieve superior mechanical properties but often suffer from abrupt interfaces that can lead to delamination. FGMs provide tailored property gradients that optimize structural integrity and lifespan, especially in applications with complex thermal and mechanical loading.

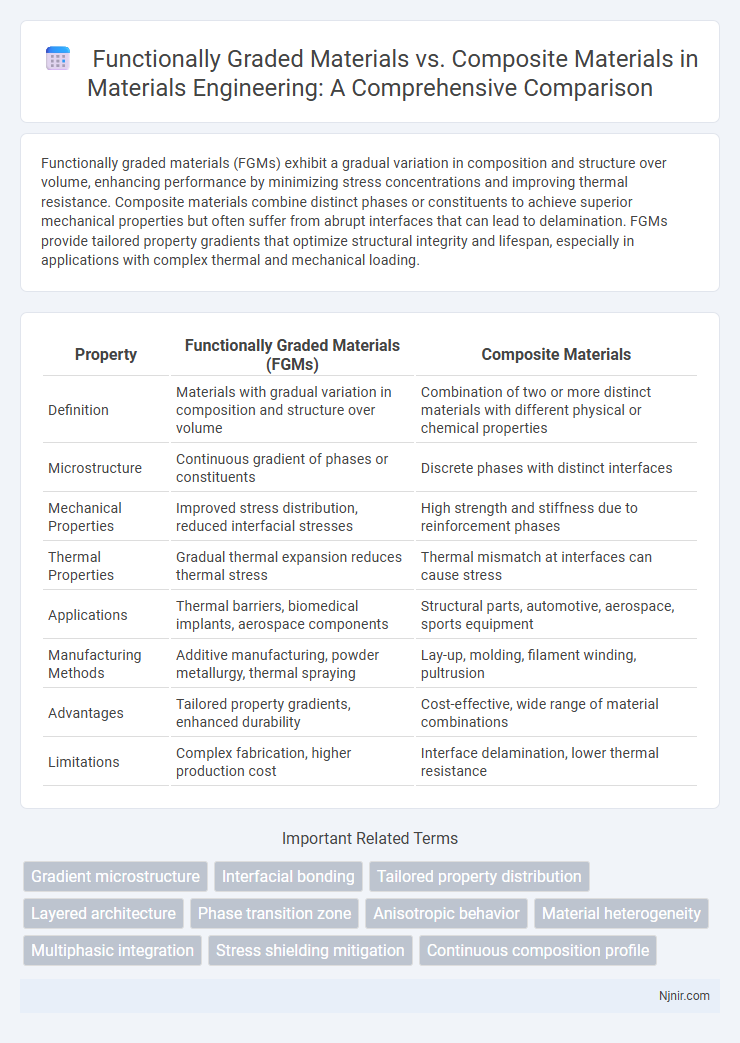

Table of Comparison

| Property | Functionally Graded Materials (FGMs) | Composite Materials |

|---|---|---|

| Definition | Materials with gradual variation in composition and structure over volume | Combination of two or more distinct materials with different physical or chemical properties |

| Microstructure | Continuous gradient of phases or constituents | Discrete phases with distinct interfaces |

| Mechanical Properties | Improved stress distribution, reduced interfacial stresses | High strength and stiffness due to reinforcement phases |

| Thermal Properties | Gradual thermal expansion reduces thermal stress | Thermal mismatch at interfaces can cause stress |

| Applications | Thermal barriers, biomedical implants, aerospace components | Structural parts, automotive, aerospace, sports equipment |

| Manufacturing Methods | Additive manufacturing, powder metallurgy, thermal spraying | Lay-up, molding, filament winding, pultrusion |

| Advantages | Tailored property gradients, enhanced durability | Cost-effective, wide range of material combinations |

| Limitations | Complex fabrication, higher production cost | Interface delamination, lower thermal resistance |

Introduction to Advanced Material Systems

Functionally graded materials (FGMs) exhibit gradual variations in composition and structure, resulting in continuous changes in their mechanical and thermal properties, unlike traditional composite materials which typically consist of distinct phases with abrupt interfaces. FGMs optimize performance under complex loading or thermal gradients by minimizing stress concentrations and enhancing durability, making them ideal for aerospace, biomedical implants, and thermal barrier coatings. Composite materials, while offering high strength-to-weight ratios through discrete reinforcement and matrix phases, often face challenges with interface bonding and property mismatches that FGMs address through their tailored gradation.

Defining Functionally Graded Materials (FGMs)

Functionally graded materials (FGMs) are advanced composites characterized by a gradual variation in composition and structure over their volume, resulting in corresponding changes in their mechanical, thermal, or chemical properties. Unlike traditional composite materials, which combine distinct phases with abrupt interfaces, FGMs exhibit continuous property gradients that enhance stress distribution and thermal resistance. This engineered gradation enables FGMs to be tailored for applications requiring smooth transitions between different functional requirements, such as thermal barrier coatings and biomedical implants.

Overview of Composite Materials

Composite materials consist of two or more distinct constituents combined at a macroscopic level to create a material with superior mechanical or physical properties compared to individual components. These materials include fiber-reinforced plastics, metal matrix composites, and ceramic matrix composites, designed to optimize strength, stiffness, and weight. Their heterogeneous microstructure enables tailored performance for aerospace, automotive, and civil engineering applications.

Fabrication Techniques: FGMs vs. Composites

Functionally graded materials (FGMs) are fabricated using advanced techniques such as powder metallurgy, additive manufacturing, and thermal spraying that enable gradual variation in composition and microstructure. Composite materials are typically produced through processes like lay-up, filament winding, pultrusion, and resin transfer molding, which combine distinct phases without continuous gradation. The fabrication of FGMs demands precise control over material gradients, while composites focus on optimizing the distribution and interface between fibers and matrix for enhanced mechanical properties.

Microstructural Differences

Functionally graded materials (FGMs) exhibit a continuous variation in composition and microstructure, enabling gradual changes in properties across the material, unlike composite materials which consist of discrete and distinct phases or layers bonded together. FGMs reduce stress concentrations and improve thermal resistance by transitioning smoothly between phases, whereas composites often face interfacial stress issues due to abrupt microstructural differences. The microstructural gradient in FGMs is engineered at the microscale to optimize performance for specific applications, setting them apart from traditional composites with clearly defined microstructural boundaries.

Mechanical Properties and Performance

Functionally graded materials (FGMs) exhibit gradual variation in composition and microstructure, enhancing mechanical properties such as fracture toughness and thermal resistance compared to traditional composite materials, which often have distinct interfaces prone to stress concentration. FGMs provide superior load distribution and reduced delamination risks, leading to improved fatigue life and impact resistance in applications like aerospace and biomedical implants. Composite materials excel in tailored stiffness and strength due to their discrete phases, but FGMs outperform composites in environments requiring smooth property transitions and resistance to thermal gradients.

Thermal and Environmental Resistance

Functionally graded materials exhibit superior thermal resistance through their gradual variation in composition, minimizing thermal stress and enhancing heat dissipation compared to traditional composite materials. Composite materials offer tailored environmental resistance by combining distinct phases, but may suffer from interfacial degradation under extreme thermal cycling. The continuous gradient in functionally graded materials significantly improves performance in high-temperature and chemically aggressive environments, making them ideal for aerospace and energy applications.

Applications in Engineering Industries

Functionally graded materials (FGMs) offer superior thermal resistance and stress distribution, making them ideal for aerospace engine components, biomedical implants, and thermal barrier coatings. Composite materials excel in structural applications such as automotive chassis, wind turbine blades, and civil infrastructure due to their high strength-to-weight ratio and tailorability. Engineering industries leverage FGMs for gradient property optimization in harsh environments, while composites dominate in lightweight, high-performance structural solutions.

Advantages and Limitations of FGMs and Composites

Functionally graded materials (FGMs) offer seamless variation in composition and properties, enhancing thermal resistance and reducing stress concentrations compared to traditional composite materials, which combine distinct phases for tailored mechanical properties and cost efficiency. FGMs face manufacturing complexities and higher production costs due to the need for precise gradient control, while composites may suffer from delamination and limited thermal stability. The choice between FGMs and composites depends on application-specific demands for structural performance, thermal management, and fabrication feasibility.

Future Trends and Research Directions

Future trends in functionally graded materials (FGMs) emphasize advanced manufacturing techniques such as additive manufacturing and nano-engineering to achieve precise control over spatial material gradients. Research directions in composite materials focus on developing smart composites with embedded sensors and self-healing capabilities to enhance performance and durability in aerospace and automotive sectors. Both material classes are advancing towards multifunctional applications, integrating tailored mechanical, thermal, and electrical properties for next-generation engineering solutions.

Gradient microstructure

Functionally graded materials feature a continuous gradient microstructure that enhances stress distribution and thermal resistance, unlike composite materials which typically have discrete microstructural interfaces.

Interfacial bonding

Functionally graded materials exhibit enhanced interfacial bonding through gradual compositional transitions, reducing stress concentrations compared to discrete interfaces in composite materials.

Tailored property distribution

Functionally graded materials exhibit continuous variations in composition and structure to achieve tailored property distribution, whereas composite materials combine distinct homogeneous constituents resulting in discrete property transitions.

Layered architecture

Functionally graded materials feature a continuous variation in composition and properties across their layered architecture, whereas composite materials consist of distinct layers or phases with abrupt interfaces.

Phase transition zone

Functionally graded materials feature a continuous phase transition zone that minimizes stress concentrations compared to the distinct interfaces found in composite materials.

Anisotropic behavior

Functionally graded materials exhibit a continuous variation in anisotropic behavior tailored through gradual changes in composition and structure, whereas composite materials display distinct anisotropic properties resulting from discrete phase interfaces and heterogeneous reinforcement distribution.

Material heterogeneity

Functionally graded materials exhibit continuous material heterogeneity with gradual variation in composition and properties, whereas composite materials display distinct and discrete phase distributions resulting in abrupt material heterogeneity.

Multiphasic integration

Functionally graded materials achieve superior multiphasic integration through gradual variation of composition and microstructure, whereas composite materials rely on discrete interfaces between distinct phases for combining multiple material properties.

Stress shielding mitigation

Functionally graded materials reduce stress shielding more effectively than traditional composite materials by gradually varying their mechanical properties to better match the stiffness of surrounding biological tissues.

Continuous composition profile

Functionally graded materials feature a continuous composition profile that seamlessly transitions material properties, unlike composite materials which have distinct, discrete interfaces between different constituents.

Functionally graded materials vs Composite materials Infographic

njnir.com

njnir.com