Shape memory alloys exhibit unique properties such as superelasticity and the ability to return to their original shape after deformation, unlike conventional alloys which typically undergo permanent plastic deformation. These alloys are especially advantageous in applications requiring high energy absorption and flexibility, such as biomedical devices and aerospace components. Their thermomechanical behavior allows for innovative design solutions that conventional alloys cannot easily achieve.

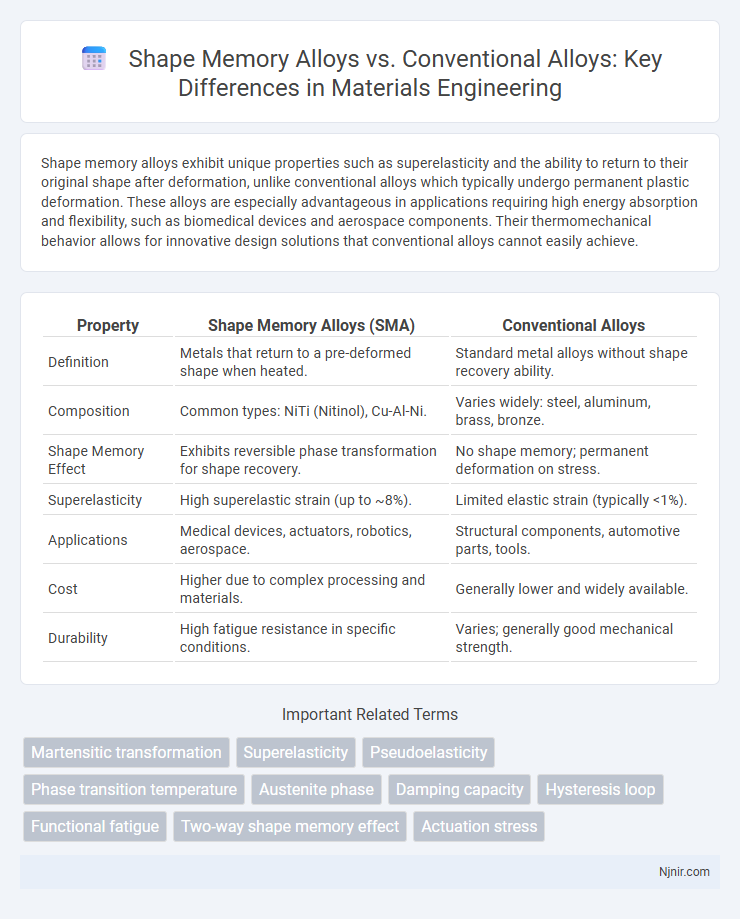

Table of Comparison

| Property | Shape Memory Alloys (SMA) | Conventional Alloys |

|---|---|---|

| Definition | Metals that return to a pre-deformed shape when heated. | Standard metal alloys without shape recovery ability. |

| Composition | Common types: NiTi (Nitinol), Cu-Al-Ni. | Varies widely: steel, aluminum, brass, bronze. |

| Shape Memory Effect | Exhibits reversible phase transformation for shape recovery. | No shape memory; permanent deformation on stress. |

| Superelasticity | High superelastic strain (up to ~8%). | Limited elastic strain (typically <1%). |

| Applications | Medical devices, actuators, robotics, aerospace. | Structural components, automotive parts, tools. |

| Cost | Higher due to complex processing and materials. | Generally lower and widely available. |

| Durability | High fatigue resistance in specific conditions. | Varies; generally good mechanical strength. |

Introduction to Shape Memory Alloys and Conventional Alloys

Shape memory alloys (SMAs) are metallic materials that can return to their original shape after deformation due to a unique phase transformation between austenite and martensite structures. Conventional alloys, composed primarily of fixed mixtures of metals like steel or aluminum alloys, exhibit plastic deformation without the ability to recover their original form once deformed. The distinctive functional properties of SMAs, including superelasticity and shape memory effects, differentiate them from conventional alloys used mainly for their mechanical strength and durability.

Fundamental Differences in Material Structure

Shape memory alloys possess a unique crystalline structure that allows them to undergo reversible phase transformations, enabling them to return to their original shape after deformation. Conventional alloys typically have stable microstructures that do not support such reversible transformations, resulting in permanent deformation upon stress. The fundamental difference lies in the martensitic transformation inherent to shape memory alloys, which is absent in traditional alloy systems.

Mechanical Properties Comparison

Shape memory alloys (SMAs) exhibit unique mechanical properties such as superelasticity and high fatigue resistance, enabling them to recover large strains up to 8% without permanent deformation, unlike conventional alloys which typically yield or fracture at much lower strain levels. SMAs demonstrate exceptional energy absorption and damping capabilities due to their phase transformation characteristics, whereas conventional alloys rely primarily on elastic and plastic deformation mechanisms. The mechanical strength of conventional alloys varies widely, but SMAs provide a combination of moderate strength with the advantage of reversible deformation, making them ideal for applications requiring flexibility and shape recovery.

Unique Functionalities of Shape Memory Alloys

Shape memory alloys (SMAs) exhibit unique functionalities such as superelasticity and the ability to return to their original shape after deformation, which conventional alloys lack. These alloys undergo reversible phase transformations enabling applications in actuators, medical devices, and adaptive structures. Their high energy absorption and fatigue resistance make SMAs ideal for smart materials in aerospace, robotics, and biomedical engineering.

Thermal Behavior and Transformation Mechanisms

Shape memory alloys exhibit unique thermal behavior characterized by reversible phase transformations between martensite and austenite, enabling them to recover their original shape upon heating. Conventional alloys typically undergo irreversible thermal expansion or contraction without phase transformation-driven shape recovery. The transformation mechanisms in shape memory alloys involve diffusionless solid-state phase changes, while conventional alloys primarily rely on atomic diffusion and grain boundary movements during thermal exposure.

Applications in Modern Engineering

Shape memory alloys (SMAs) excel in modern engineering applications such as aerospace actuators, biomedical stents, and adaptive structures due to their unique ability to undergo deformation and return to pre-defined shapes upon temperature change. Conventional alloys remain prevalent in applications requiring high strength, corrosion resistance, and wear performance like automotive components, construction materials, and heavy machinery parts. The distinct thermomechanical properties of SMAs enable smart system integration and lightweight design, complementing the robustness and cost-effectiveness of traditional alloy materials.

Processing and Fabrication Techniques

Shape memory alloys (SMAs) require specialized processing techniques such as thermo-mechanical treatments and controlled thermal cycling to achieve their unique phase transformation properties, unlike conventional alloys that rely primarily on standard melting, casting, and mechanical forming methods. Fabrication of SMAs often involves precise control of composition and microstructure through processes like rapid solidification, powder metallurgy, or additive manufacturing to ensure desired superelastic and shape memory effects. Conventional alloys benefit from more established, large-scale fabrication methods including rolling, forging, and extrusion without the need for phase transformation optimization.

Cost Analysis and Economic Considerations

Shape memory alloys (SMAs) generally present higher upfront costs than conventional alloys due to complex manufacturing processes and specialized raw materials like nickel-titanium (NiTi). Despite this, SMAs offer long-term economic benefits through reduced maintenance, enhanced durability, and unique functional properties such as superelasticity and thermal shape recovery, which can lower replacement and operational expenses. Conventional alloys remain cost-effective for standard applications but may incur higher lifecycle costs in environments demanding adaptive or high-performance materials.

Lifespan and Durability Evaluation

Shape memory alloys (SMAs) demonstrate superior lifespan and durability compared to conventional alloys due to their unique ability to undergo reversible phase transformations without plastic deformation, enhancing fatigue resistance. SMAs typically endure thousands to millions of cyclic loads with minimal functional degradation, whereas conventional alloys often experience microcracking and permanent deformation under similar conditions. Advanced evaluations show that SMAs maintain mechanical properties and shape recovery efficiency over prolonged use, making them ideal for applications requiring long-term reliability and durability in dynamic environments.

Future Trends in Alloy Development

Future trends in alloy development emphasize integrating advanced shape memory alloys (SMAs) with enhanced functional properties such as increased fatigue resistance, higher transformation temperatures, and improved biocompatibility. Research prioritizes nano-engineered microstructures and additive manufacturing techniques to tailor alloy compositions for adaptive and smart applications in aerospace, biomedical devices, and robotics. Conventional alloys continue to evolve with lightweight, high-strength compositions, but SMAs lead innovation by enabling self-healing and reversible deformation capabilities fundamental for next-generation smart materials.

Martensitic transformation

Shape memory alloys exhibit unique martensitic transformation enabling reversible phase changes and superior shape recovery, unlike conventional alloys that undergo irreversible structural changes during deformation.

Superelasticity

Shape memory alloys exhibit superior superelasticity compared to conventional alloys, enabling them to undergo large strains and recover their original shape without permanent deformation.

Pseudoelasticity

Shape memory alloys exhibit superior pseudoelasticity, enabling reversible strain recovery up to 8% compared to conventional alloys' limited elasticity under 1%.

Phase transition temperature

Shape memory alloys exhibit a distinct phase transition temperature typically between -50degC and 130degC, enabling reversible transformation and shape recovery, whereas conventional alloys generally lack such a defined thermally induced phase transition.

Austenite phase

Shape memory alloys exhibit a reversible austenite phase transformation enabling superelasticity and shape recovery, unlike conventional alloys whose austenite phase lacks such functional phase memory properties.

Damping capacity

Shape memory alloys exhibit superior damping capacity compared to conventional alloys due to their unique ability to undergo reversible phase transformations that dissipate mechanical energy effectively.

Hysteresis loop

Shape memory alloys exhibit a distinctive hysteresis loop characterized by reversible phase transformations and energy dissipation, unlike conventional alloys that typically show linear elastic behavior with minimal hysteresis.

Functional fatigue

Shape memory alloys exhibit superior functional fatigue resistance compared to conventional alloys due to their ability to undergo reversible phase transformations without permanent deformation.

Two-way shape memory effect

Two-way shape memory effect in shape memory alloys enables reversible deformation and recovery upon temperature changes, unlike conventional alloys which lack this reversible phase transformation capability.

Actuation stress

Shape memory alloys generate significantly higher actuation stress, often exceeding 200 MPa, compared to conventional alloys which typically produce actuation stress below 100 MPa, making SMAs ideal for high-force actuator applications.

Shape memory alloys vs Conventional alloys Infographic

njnir.com

njnir.com