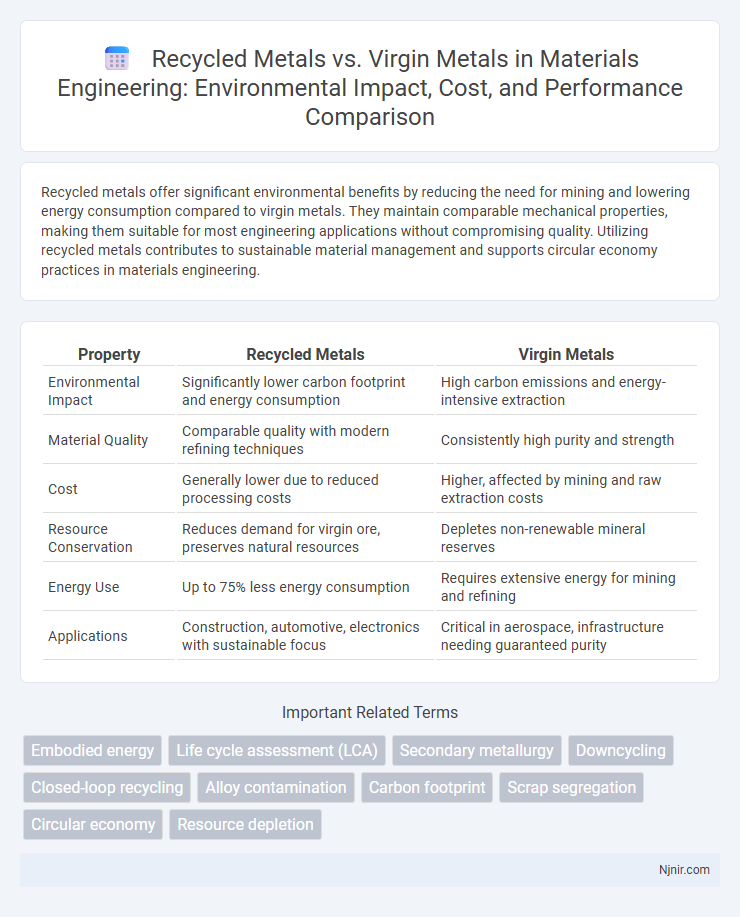

Recycled metals offer significant environmental benefits by reducing the need for mining and lowering energy consumption compared to virgin metals. They maintain comparable mechanical properties, making them suitable for most engineering applications without compromising quality. Utilizing recycled metals contributes to sustainable material management and supports circular economy practices in materials engineering.

Table of Comparison

| Property | Recycled Metals | Virgin Metals |

|---|---|---|

| Environmental Impact | Significantly lower carbon footprint and energy consumption | High carbon emissions and energy-intensive extraction |

| Material Quality | Comparable quality with modern refining techniques | Consistently high purity and strength |

| Cost | Generally lower due to reduced processing costs | Higher, affected by mining and raw extraction costs |

| Resource Conservation | Reduces demand for virgin ore, preserves natural resources | Depletes non-renewable mineral reserves |

| Energy Use | Up to 75% less energy consumption | Requires extensive energy for mining and refining |

| Applications | Construction, automotive, electronics with sustainable focus | Critical in aerospace, infrastructure needing guaranteed purity |

Introduction to Recycled and Virgin Metals

Recycled metals are derived from scrap materials that have been reprocessed and reshaped for reuse, conserving natural resources and reducing energy consumption compared to virgin metals. Virgin metals are extracted directly from mineral ores through mining and refining processes, requiring significant energy input and environmental disruption. The choice between recycled and virgin metals impacts sustainability, production costs, and ecological footprint in various industries.

Raw Material Sources and Extraction Processes

Recycled metals originate from scrap materials collected through processes like shredding and melting, significantly reducing the need for raw material extraction and lowering environmental impact. Virgin metals involve mining ores from natural deposits, requiring extensive excavation, refining, and energy-intensive procedures to extract pure metals. The shift from virgin to recycled metals conserves natural resources, minimizes habitat disruption, and decreases greenhouse gas emissions associated with mining operations.

Energy Consumption and Environmental Impact

Recycled metals consume up to 95% less energy compared to virgin metals, significantly reducing greenhouse gas emissions during production. The extraction and processing of virgin metals involve extensive mining operations, leading to habitat destruction, soil erosion, and water pollution. Utilizing recycled metals not only conserves natural resources but also minimizes environmental degradation and lowers carbon footprints associated with metal manufacturing.

Material Properties: Strength and Durability

Recycled metals often retain comparable strength and durability to virgin metals, making them suitable for most construction and manufacturing applications. The recycling process can slightly alter the microstructure, but modern techniques ensure minimal impact on mechanical properties such as tensile strength and hardness. Utilizing recycled metals contributes to sustainability without significantly compromising material performance.

Cost Analysis: Economic Considerations

Recycled metals typically offer significant cost savings compared to virgin metals due to lower energy consumption and reduced raw material extraction expenses. The price volatility of virgin metals, influenced by mining operations and geopolitical factors, often leads to higher and less predictable costs. Incorporating recycled metals into manufacturing processes supports economic sustainability by minimizing operational expenditures and stabilizing supply chain pricing.

Applications in Modern Manufacturing

Recycled metals play a crucial role in modern manufacturing by reducing resource consumption and lowering energy costs while maintaining material quality for applications in automotive, aerospace, and construction industries. Virgin metals offer superior purity and mechanical properties essential for high-performance electronics, medical devices, and precision engineering components. Combining recycled and virgin metals optimizes supply chains, enhances sustainability, and meets stringent performance standards across diverse manufacturing sectors.

Purity and Quality Control Challenges

Recycled metals often face purity and quality control challenges due to the presence of contaminants and alloy variations, which require advanced sorting and refining technologies to achieve standards comparable to virgin metals. Virgin metals typically offer higher initial purity levels, simplifying quality control processes and ensuring consistent material properties essential for high-performance applications. Innovations in sensor-based sorting and electrochemical refining are critical to improving the quality of recycled metals to meet industry specifications.

Lifecycle Assessment and Sustainability

Recycled metals significantly reduce environmental impacts across their lifecycle by lowering energy consumption by up to 95% compared to virgin metals, resulting in fewer greenhouse gas emissions and less mining-related habitat destruction. Lifecycle assessment demonstrates that using recycled metals conserves natural resources, reduces water use, and minimizes waste generation throughout production and disposal stages. Emphasizing recycled metals in manufacturing supports circular economy principles, enhancing sustainability by decreasing the carbon footprint and promoting resource efficiency.

Industry Trends and Market Demand

Recycled metals account for a growing share of the global metals supply, driven by increased environmental regulations and corporate sustainability goals targeting reductions in carbon emissions. The demand for recycled metals, especially aluminum and copper, is rising within industries such as automotive, construction, and electronics due to lower energy consumption and cost benefits compared to virgin metals. Market trends indicate a shift towards circular economy practices, with investments in advanced recycling technologies enhancing material recovery rates and improving the quality of recycled metal outputs.

Future Innovations in Metal Recycling

Future innovations in metal recycling emphasize advanced technologies such as AI-driven sorting systems and electrochemical processes to improve the separation and recovery of recycled metals from complex waste streams. Emerging methods like bioleaching and plasma arc recycling enhance the efficiency and environmental sustainability of reclaiming valuable metals compared to traditional virgin metal extraction. These advancements promise to reduce energy consumption, lower carbon emissions, and increase the supply of high-quality recycled metals for industrial applications.

Embodied energy

Recycled metals significantly reduce embodied energy by up to 95% compared to virgin metals, lowering environmental impact and energy consumption in manufacturing processes.

Life cycle assessment (LCA)

Recycled metals significantly reduce environmental impact in life cycle assessments (LCA) by lowering energy consumption, greenhouse gas emissions, and resource depletion compared to virgin metals.

Secondary metallurgy

Secondary metallurgy optimizes recycled metals by refining impurities and enhancing alloy properties to match or exceed the quality of virgin metals.

Downcycling

Recycled metals often undergo downcycling, resulting in lower-quality materials compared to virgin metals, which maintain superior strength and purity for industrial applications.

Closed-loop recycling

Closed-loop recycling of recycled metals significantly reduces environmental impact and energy consumption compared to using virgin metals, enabling sustainable metal production with minimal resource depletion.

Alloy contamination

Recycled metals often face challenges with alloy contamination due to mixed scrap sources, resulting in variable composition that can compromise material properties compared to the more consistent purity of virgin metals.

Carbon footprint

Recycled metals reduce carbon emissions by up to 90% compared to virgin metals, significantly minimizing the overall carbon footprint in metal production.

Scrap segregation

Efficient scrap segregation enhances the quality and economic value of recycled metals compared to virgin metals by minimizing contamination and improving material purity.

Circular economy

Recycled metals reduce environmental impact and resource depletion by maintaining material value within the circular economy, unlike virgin metals that require energy-intensive extraction and generate significant waste.

Resource depletion

Recycled metals significantly reduce resource depletion by conserving finite virgin metal reserves and minimizing the environmental impact of mining activities.

Recycled metals vs Virgin metals Infographic

njnir.com

njnir.com