3D printing offers unparalleled design freedom and rapid prototyping capabilities, enabling the production of complex geometries without the need for costly molds. Injection molding excels in high-volume manufacturing with consistent material properties and faster cycle times, making it cost-effective for large production runs. Material selection and application requirements determine the optimal process between additive and traditional manufacturing techniques.

Table of Comparison

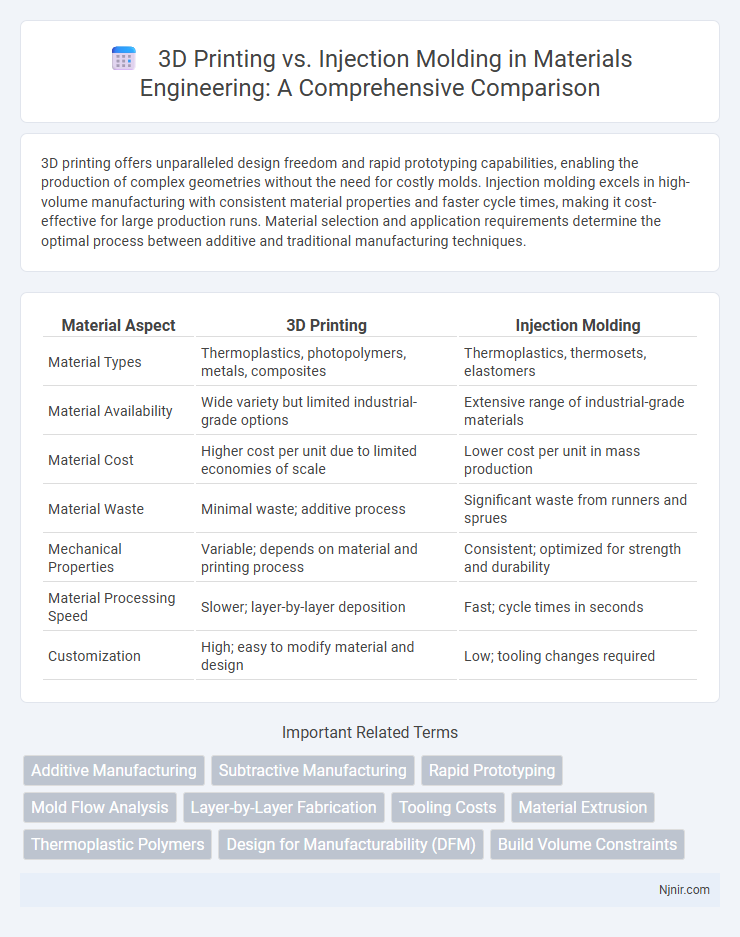

| Material Aspect | 3D Printing | Injection Molding |

|---|---|---|

| Material Types | Thermoplastics, photopolymers, metals, composites | Thermoplastics, thermosets, elastomers |

| Material Availability | Wide variety but limited industrial-grade options | Extensive range of industrial-grade materials |

| Material Cost | Higher cost per unit due to limited economies of scale | Lower cost per unit in mass production |

| Material Waste | Minimal waste; additive process | Significant waste from runners and sprues |

| Mechanical Properties | Variable; depends on material and printing process | Consistent; optimized for strength and durability |

| Material Processing Speed | Slower; layer-by-layer deposition | Fast; cycle times in seconds |

| Customization | High; easy to modify material and design | Low; tooling changes required |

Introduction to 3D Printing and Injection Molding

3D printing, also known as additive manufacturing, builds objects layer by layer directly from digital designs, enabling rapid prototyping and complex geometries with minimal material waste. Injection molding involves forcing molten material into a mold cavity to produce high volumes of identical parts with excellent surface finish and mechanical properties. While 3D printing excels in customization and low-volume production, injection molding is preferred for mass manufacturing due to its scalability and cost-efficiency per unit.

Process Overview: 3D Printing vs Injection Molding

3D printing builds objects layer by layer from digital models using materials like plastics or metals, enabling rapid prototyping and customization with minimal setup. Injection molding involves injecting molten material into a precision-engineered steel mold cavity, producing high volumes of consistent parts with fast cycle times after an initial tooling investment. The 3D printing process offers flexibility and design complexity, while injection molding excels in efficiency and scalability for mass production.

Material Compatibility and Selection

3D printing offers extensive material compatibility, including thermoplastics, resins, metals, and composites, enabling rapid prototyping with diverse properties. Injection molding primarily uses thermoplastics like ABS, polypropylene, and polyethylene, optimized for high-volume production but limited in material variety. Material selection in 3D printing prioritizes customization and flexibility, while injection molding emphasizes durability and scalability for consistent part quality.

Production Speed and Scalability

Injection molding offers significantly faster production speeds for high-volume manufacturing, enabling the creation of thousands of identical parts within hours due to its automated process and reusable molds. In contrast, 3D printing has slower production rates, making it ideal for low-volume or prototype runs where customization and complexity are prioritized over speed. Scalability is a strong advantage of injection molding as it easily scales from small to mass production, whereas 3D printing requires multiple printers and longer timeframes to increase output.

Cost Analysis: Prototyping to Mass Manufacturing

3D printing offers lower upfront costs and faster iteration times, making it ideal for prototyping and small-batch production with minimal material waste. Injection molding requires significant initial investment in tooling and molds but delivers consistent unit costs that decrease substantially with high-volume manufacturing. For mass production exceeding thousands of units, injection molding typically becomes more cost-effective due to economies of scale, while 3D printing remains optimal for low-volume, customized runs.

Design Flexibility and Complexity

3D printing offers unparalleled design flexibility by enabling the creation of intricate geometries and internal structures that are impossible or cost-prohibitive with injection molding. Injection molding excels in producing high volumes of parts with consistent quality but is limited by mold design constraints and significant upfront tooling costs. Complex designs in injection molding often require costly mold modifications or multi-part assemblies, whereas 3D printing accommodates rapid prototyping and customization without additional tooling expenses.

Surface Finish and Mechanical Properties

3D printing offers varied surface finishes depending on the technology, with stereolithography (SLA) providing smoother surfaces compared to fused deposition modeling (FDM), but generally, injection molding achieves superior surface finish due to high-pressure molding and polished molds. Mechanically, injection molding produces parts with better uniformity, strength, and wear resistance, benefiting from optimized resin flow and cooling, whereas 3D printed parts often exhibit anisotropic properties and layer adhesion weaknesses. Surface roughness values in injection molding typically reach 0.8 microns or better, contrasting with 3D printed parts which can range from 5 to 20 microns without post-processing.

Environmental Impact and Sustainability

3D printing reduces material waste by precisely depositing only the necessary amount of filament, contrasting with injection molding's significant scrap from mold creation and excess parts. Injection molding requires large energy consumption for heating and cooling molds, whereas 3D printing typically uses less energy, especially for low-volume production. However, injection molding supports mass production efficiency, decreasing per-unit environmental impact over high volumes, while 3D printing excels in sustainable prototyping and customization with minimal supply chain demands.

Typical Applications in Materials Engineering

3D printing excels in producing complex geometries and prototypes with rapid iteration cycles, making it ideal for custom, low-volume parts and experimental materials in materials engineering. Injection molding is preferred for mass production of high-precision, durable components using thermoplastics and thermosetting polymers, offering superior surface finish and mechanical properties. Both techniques are integral in materials engineering, with 3D printing facilitating innovation and injection molding enabling scalable manufacturing.

Future Trends in Additive and Traditional Manufacturing

Future trends in 3D printing emphasize advancements in multi-material capabilities, faster production speeds, and improved surface finishes, enabling more complex and customized designs in additive manufacturing. Injection molding continues to evolve with innovations in automation, materials science, and hybrid manufacturing processes that combine traditional molding with additive techniques for enhanced efficiency and flexibility. The integration of AI-driven design optimization and real-time process monitoring is expected to blur the lines between 3D printing and injection molding, driving a more adaptive and responsive manufacturing landscape.

Additive Manufacturing

Additive manufacturing, or 3D printing, enables rapid prototyping and complex geometries with lower upfront costs compared to injection molding's high-volume, cost-efficient production of uniform parts.

Subtractive Manufacturing

Subtractive manufacturing differs from 3D printing and injection molding by removing material from a solid block, enabling precise and complex component fabrication with minimal waste.

Rapid Prototyping

3D printing enables rapid prototyping with quick iterations and low setup costs, while injection molding offers faster production for high-volume prototypes but requires longer lead times and higher tooling expenses.

Mold Flow Analysis

Mold Flow Analysis in injection molding optimizes material flow and reduces defects, whereas 3D printing eliminates the need for molds but lacks comparable flow simulation for complex part production.

Layer-by-Layer Fabrication

3D printing employs layer-by-layer fabrication to build complex geometries with high customization, whereas injection molding uses a single-step process ideal for mass production but less flexible in design changes.

Tooling Costs

3D printing eliminates high tooling costs required for injection molding, making it cost-effective for low-volume production and prototype development.

Material Extrusion

Material extrusion in 3D printing offers rapid prototyping and low-volume production flexibility, while injection molding provides high-volume manufacturing efficiency with consistent material properties.

Thermoplastic Polymers

Thermoplastic polymers in 3D printing offer rapid prototyping and design flexibility, while injection molding provides high-volume production efficiency and consistent material properties.

Design for Manufacturability (DFM)

3D printing offers greater design flexibility and rapid prototyping for Design for Manufacturability (DFM), while injection molding provides cost-efficient high-volume production with strict design constraints for toolability and material flow.

Build Volume Constraints

3D printing offers flexible build volume options limited primarily by printer size, while injection molding requires fixed mold sizes that dictate consistent but often larger production volumes.

3D printing vs Injection molding Infographic

njnir.com

njnir.com