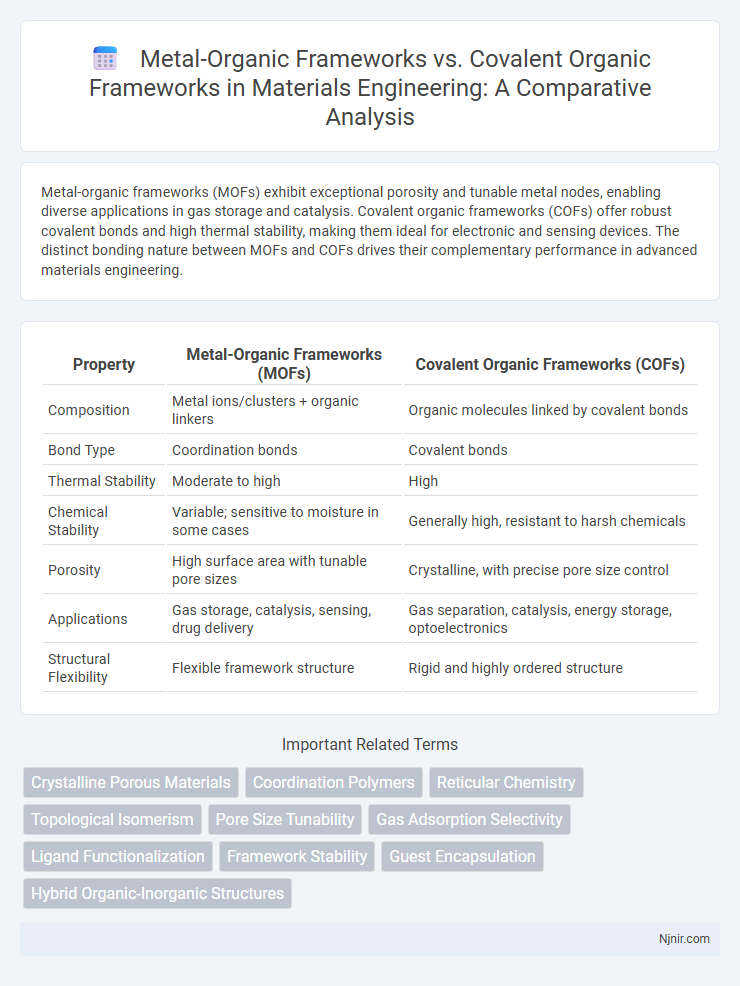

Metal-organic frameworks (MOFs) exhibit exceptional porosity and tunable metal nodes, enabling diverse applications in gas storage and catalysis. Covalent organic frameworks (COFs) offer robust covalent bonds and high thermal stability, making them ideal for electronic and sensing devices. The distinct bonding nature between MOFs and COFs drives their complementary performance in advanced materials engineering.

Table of Comparison

| Property | Metal-Organic Frameworks (MOFs) | Covalent Organic Frameworks (COFs) |

|---|---|---|

| Composition | Metal ions/clusters + organic linkers | Organic molecules linked by covalent bonds |

| Bond Type | Coordination bonds | Covalent bonds |

| Thermal Stability | Moderate to high | High |

| Chemical Stability | Variable; sensitive to moisture in some cases | Generally high, resistant to harsh chemicals |

| Porosity | High surface area with tunable pore sizes | Crystalline, with precise pore size control |

| Applications | Gas storage, catalysis, sensing, drug delivery | Gas separation, catalysis, energy storage, optoelectronics |

| Structural Flexibility | Flexible framework structure | Rigid and highly ordered structure |

Introduction to Metal-Organic Frameworks (MOFs) and Covalent Organic Frameworks (COFs)

Metal-Organic Frameworks (MOFs) are porous crystalline materials constructed from metal ions or clusters coordinated to organic ligands, offering high surface area and tunable porosity ideal for gas storage, separation, and catalysis. Covalent Organic Frameworks (COFs) are entirely organic, crystalline polymers formed through strong covalent bonds between light elements, providing structural stability and design flexibility for applications in sensing, energy storage, and molecular filtration. Both frameworks enable precise control over pore size and functionality, but MOFs emphasize metal-ligand coordination chemistry while COFs focus on covalent bonding patterns for material customization.

Structural Differences Between MOFs and COFs

Metal-organic frameworks (MOFs) consist of metal ions or clusters coordinated to organic ligands, forming a crystalline structure with high porosity, while covalent organic frameworks (COFs) are composed entirely of light elements linked by strong covalent bonds creating two- or three-dimensional networks. MOFs feature metal nodes serving as coordination centers, enabling diverse geometries and adjustable pore sizes, whereas COFs rely on covalent bonds leading to more robust, chemically stable architectures. The presence of metal ions in MOFs contributes to their tunable functionalities and catalytic properties, contrasting with the purely organic composition of COFs that ensures lightweight, thermally stable, and electronically tunable materials.

Synthesis Methods of MOFs and COFs

Metal-organic frameworks (MOFs) are primarily synthesized using solvothermal or hydrothermal methods, involving the reaction of metal ions or clusters with organic ligands under controlled temperature and pressure conditions to form crystalline porous structures. Covalent organic frameworks (COFs) are typically synthesized through reversible covalent bond formation strategies, such as Schiff base condensation or boronic acid dehydration, enabling the creation of highly ordered crystalline networks via dynamic covalent chemistry. Both methods emphasize precise control over reaction conditions to achieve high crystallinity and structural integrity, but MOFs rely on metal-ligand coordination while COFs depend on stable covalent linkages.

Porosity and Surface Area Comparison

Metal-organic frameworks (MOFs) typically exhibit higher porosity and larger surface areas compared to covalent organic frameworks (COFs) due to their coordination bonds between metal nodes and organic linkers, which create extensive and tunable pore networks. MOFs can achieve surface areas exceeding 7,000 m2/g, surpassing most COFs that generally range between 1,000 and 4,000 m2/g. The diverse metal centers in MOFs allow precise control over pore size and volume, enhancing guest molecule adsorption beyond the predominantly carbon-based COFs with covalent bonds.

Thermal and Chemical Stability

Metal-organic frameworks (MOFs) generally exhibit moderate thermal stability, often decomposing between 200degC and 400degC, whereas covalent organic frameworks (COFs) can withstand higher temperatures, frequently above 400degC due to robust covalent bonding. Chemical stability in MOFs is influenced by the metal node and organic linker combination, with some frameworks vulnerable to moisture and acidic conditions, while COFs typically demonstrate superior chemical resistance owing to strong covalent linkages that resist hydrolysis and corrosive environments. The enhanced thermal and chemical stability of COFs makes them more suitable for applications requiring harsh operational conditions compared to MOFs.

Applications in Gas Storage and Separation

Metal-organic frameworks (MOFs) exhibit exceptional surface area and tunable pore structures, making them highly efficient for gas storage applications such as hydrogen and methane due to their strong metal-ligand coordination sites. Covalent organic frameworks (COFs) provide greater structural stability and chemical resistance with customizable pore sizes, ideally suited for selective gas separation of CO2 and other industrial gases through precise molecular sieving. Both MOFs and COFs are extensively researched for enhancing adsorption capacity and selectivity in carbon capture and clean energy technologies.

Catalysis: MOFs vs COFs Performance

Metal-organic frameworks (MOFs) exhibit superior catalytic activity due to their diverse metal nodes that provide active sites for various reactions, whereas covalent organic frameworks (COFs) offer high stability and tunable pore environments enhancing selectivity in catalysis. MOFs generally show higher catalytic efficiency in processes like CO2 reduction and hydrogen evolution, driven by their intrinsic metal centers, while COFs excel in photocatalysis and acid-base catalysis due to their extended p-conjugation and robust covalent bonding. The choice between MOFs and COFs for catalysis hinges on the targeted reaction mechanism, with MOFs favored for metal-centered catalysis and COFs for metal-free or hybrid catalytic systems.

Electronic and Optical Properties

Metal-organic frameworks (MOFs) exhibit tunable electronic properties primarily due to the incorporation of metal nodes that facilitate electron mobility and redox activity, making them suitable for applications in sensing and catalysis. Covalent organic frameworks (COFs) possess highly conjugated organic linkers that enable extended p-electron delocalization, resulting in superior optical properties such as high fluorescence and enhanced light absorption for optoelectronic devices. Compared to MOFs, COFs generally offer greater electronic conductivity and stability in optical performance due to their robust covalent bonds and planar structures facilitating efficient charge transport.

Sustainability and Environmental Impact

Metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) both offer sustainable solutions for environmental applications, with MOFs excelling in gas storage and separation due to their high surface area and tunable pore sizes. COFs demonstrate superior chemical stability and recyclability, making them more durable for long-term use in water purification and pollutant removal. The low-energy synthesis and potential for biodegradability enhance the environmental benefits of COFs, while MOFs' ability to capture greenhouse gases contributes significantly to reducing carbon footprints.

Future Perspectives and Challenges

Metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) both exhibit significant potential in gas storage, catalysis, and sensing applications due to their tunable porosity and functional diversity. Future perspectives emphasize enhancing the stability and scalability of MOFs and COFs while developing more precise synthetic techniques to tailor their structural and chemical properties for specific industrial uses. Major challenges include improving framework robustness under harsh conditions and advancing cost-effective production methods to facilitate commercial adoption.

Crystalline Porous Materials

Metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) are crystalline porous materials distinguished by MOFs' metal ion nodes linked by organic ligands and COFs' purely covalent organic bond networks, offering tunable pore sizes and high surface areas critical for gas storage, catalysis, and separation applications.

Coordination Polymers

Metal-organic frameworks (MOFs) are coordination polymers formed by metal ions linked to organic ligands creating porous crystalline structures, whereas covalent organic frameworks (COFs) are purely organic coordination polymers connected by strong covalent bonds, offering enhanced chemical stability and tunable porosity.

Reticular Chemistry

Reticular chemistry enables the precise design of metal-organic frameworks (MOFs) using metal ions and organic linkers, while covalent organic frameworks (COFs) are synthesized solely from organic building blocks linked by strong covalent bonds for enhanced stability and tunability.

Topological Isomerism

Topological isomerism in metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) arises from variations in the connectivity and arrangement of their building units, influencing their pore structures, stability, and functional properties.

Pore Size Tunability

Metal-organic frameworks exhibit superior pore size tunability compared to covalent organic frameworks due to their diverse metal nodes and flexible organic linkers enabling precise control of porosity for targeted applications.

Gas Adsorption Selectivity

Metal-organic frameworks (MOFs) typically exhibit higher gas adsorption selectivity than covalent organic frameworks (COFs) due to their tunable metal nodes and diverse pore environments tailored for specific gas molecules.

Ligand Functionalization

Ligand functionalization in metal-organic frameworks (MOFs) enables diverse chemical modifications and tunable porosity, while covalent organic frameworks (COFs) offer robust covalent bonding leading to enhanced chemical stability and precise functional group integration.

Framework Stability

Metal-organic frameworks exhibit higher framework stability under moisture and thermal stress compared to covalent organic frameworks due to their strong metal-ligand coordination bonds.

Guest Encapsulation

Metal-organic frameworks (MOFs) offer higher guest encapsulation capacity and tunable pore environments compared to covalent organic frameworks (COFs), enabling more efficient and selective molecular trapping.

Hybrid Organic-Inorganic Structures

Hybrid organic-inorganic structures combine the high porosity and tunable functionality of metal-organic frameworks (MOFs) with the exceptional chemical stability and design versatility of covalent organic frameworks (COFs), enabling advanced applications in gas storage, catalysis, and sensing.

metal-organic frameworks vs covalent organic frameworks Infographic

njnir.com

njnir.com