Self-healing polymers possess intrinsic or extrinsic repair mechanisms that autonomously restore material integrity after damage, significantly enhancing durability and lifecycle performance in materials engineering. Shape-memory polymers, on the other hand, can return from a deformed state to their original shape upon exposure to specific stimuli such as heat, providing adaptive functionality for applications requiring reversible shape changes. While self-healing polymers prioritize damage recovery to extend service life, shape-memory polymers focus on dynamic shape transformation for responsive and multifunctional materials.

Table of Comparison

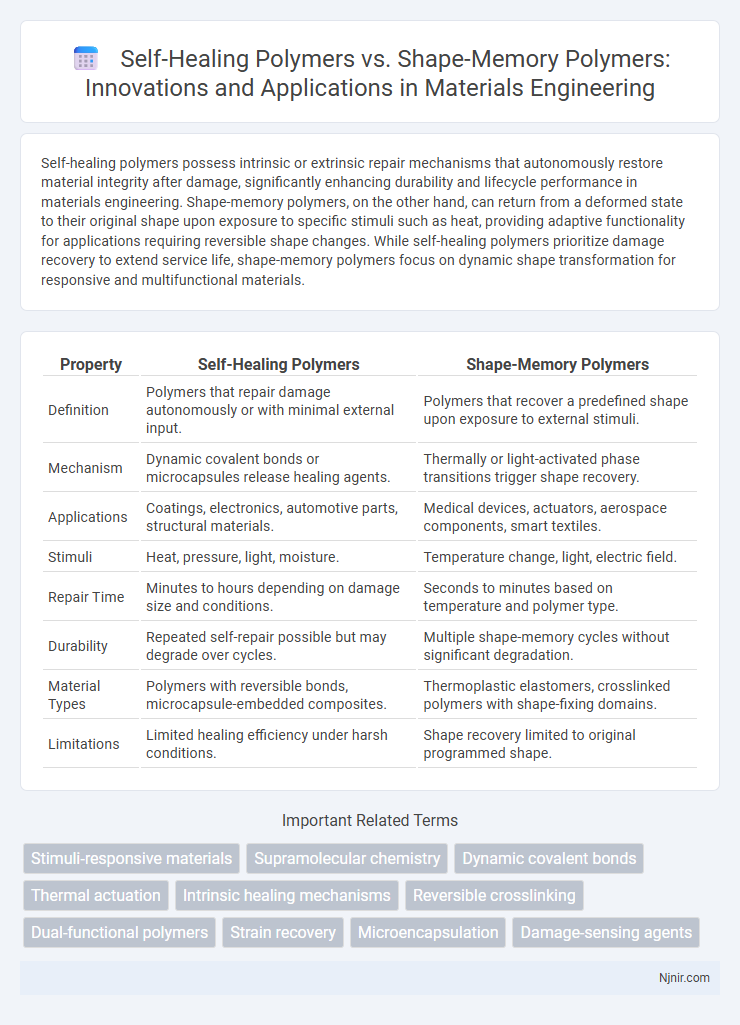

| Property | Self-Healing Polymers | Shape-Memory Polymers |

|---|---|---|

| Definition | Polymers that repair damage autonomously or with minimal external input. | Polymers that recover a predefined shape upon exposure to external stimuli. |

| Mechanism | Dynamic covalent bonds or microcapsules release healing agents. | Thermally or light-activated phase transitions trigger shape recovery. |

| Applications | Coatings, electronics, automotive parts, structural materials. | Medical devices, actuators, aerospace components, smart textiles. |

| Stimuli | Heat, pressure, light, moisture. | Temperature change, light, electric field. |

| Repair Time | Minutes to hours depending on damage size and conditions. | Seconds to minutes based on temperature and polymer type. |

| Durability | Repeated self-repair possible but may degrade over cycles. | Multiple shape-memory cycles without significant degradation. |

| Material Types | Polymers with reversible bonds, microcapsule-embedded composites. | Thermoplastic elastomers, crosslinked polymers with shape-fixing domains. |

| Limitations | Limited healing efficiency under harsh conditions. | Shape recovery limited to original programmed shape. |

Introduction to Smart Polymers in Materials Engineering

Smart polymers in materials engineering encompass self-healing polymers and shape-memory polymers, both designed to respond dynamically to external stimuli. Self-healing polymers autonomously repair damages through reversible chemical bonds or microcapsules containing healing agents, enhancing durability and lifespan. Shape-memory polymers return to a predetermined shape upon exposure to heat, light, or other triggers, enabling applications in adaptive structures and biomedical devices.

Defining Self-Healing Polymers: Mechanisms and Applications

Self-healing polymers possess intrinsic or extrinsic mechanisms enabling autonomous repair of microcracks or damages, primarily through reversible covalent bonds, microcapsule rupturing, or supramolecular interactions. These materials are extensively applied in coatings, electronics, and biomedical devices to enhance durability and extend service life by restoring mechanical integrity after damage. In contrast, shape-memory polymers primarily recover predefined shapes upon external stimuli, focusing on deformation recovery rather than self-repair, making them ideal for actuation and biomedical implants.

Understanding Shape-Memory Polymers: Functionality and Use Cases

Shape-memory polymers (SMPs) are smart materials capable of returning from a deformed state to their original shape upon exposure to an external stimulus such as heat, light, or electricity. Their functionality relies on a dual-segment design that includes a fixed phase maintaining permanent shape and a reversible switch phase enabling temporary shape deformation. Widely used in medical devices, aerospace components, and flexible electronics, SMPs provide precise actuation, biocompatibility, and structural resilience for advanced engineering applications.

Molecular Architecture: Self-Healing vs Shape-Memory Polymers

Self-healing polymers feature dynamic covalent bonds or reversible supramolecular interactions within their molecular architecture, enabling autonomous repair of mechanical damage through bond reformation. Shape-memory polymers incorporate cross-linked networks or segmented block copolymers designed to fix and recover temporary shapes via thermal or other external stimuli triggering phase transitions. The molecular design in self-healing polymers emphasizes bond reversibility for damage repair, whereas shape-memory polymers focus on switching domains to achieve shape fixation and recovery.

Triggering Mechanisms and Stimuli Response

Self-healing polymers autonomously repair damage through mechanisms triggered by stimuli such as heat, light, or chemical exposure, enabling bond reformation or material flow restoration. Shape-memory polymers respond to specific stimuli like temperature changes, light, or electrical input by transitioning from a temporary shape back to their original form through reversible phase transitions or molecular realignment. The distinct triggering mechanisms--chemical reactions in self-healing versus physical shape recovery in shape-memory polymers--define their respective stimuli responsiveness and functional applications.

Mechanical Performance Comparison

Self-healing polymers exhibit superior mechanical resilience by autonomously repairing micro-cracks and damages, extending the material's lifespan under cyclic loading conditions. Shape-memory polymers provide unique mechanical performance through reversible deformation capabilities, allowing return to their original shape upon thermal or mechanical stimuli, but they often have lower fracture toughness compared to self-healing variants. Comparative studies show self-healing polymers sustain higher fatigue resistance and damage tolerance, whereas shape-memory polymers excel in applications demanding reversible shape recovery with moderate mechanical strength.

Durability and Lifespan in Practical Applications

Self-healing polymers enhance durability by autonomously repairing microcracks and damage, extending the material's functional lifespan in applications such as coatings, electronics, and aerospace components. Shape-memory polymers exhibit durability through reversible deformation and recovery, but their lifespan can be limited by repeated cycling and environmental stress factors in medical devices and actuators. Practical use favors self-healing polymers for long-term structural integrity, while shape-memory polymers excel in applications requiring reversible shape changes with moderate durability demands.

Manufacturing and Processing Techniques

Self-healing polymers often require advanced manufacturing methods such as microencapsulation or embedding healing agents within the polymer matrix, enabling autonomous repair through chemical reactions triggered by damage. Shape-memory polymers are processed using techniques like extrusion, injection molding, and 3D printing, which allow precise control over their thermal and mechanical properties to achieve the desired shape recovery behavior. Both polymer types benefit from additive manufacturing for complex geometries, but self-healing polymers demand more intricate processing to integrate stimuli-responsive components essential for healing functionality.

Sustainability and Environmental Impacts

Self-healing polymers enhance sustainability by extending the lifespan of products through autonomous repair mechanisms, reducing material waste and resource consumption. Shape-memory polymers contribute to environmental benefits by enabling reversible deformation, which supports recycling and reduces the need for new raw materials. Both technologies mitigate environmental impacts by encouraging circular economy principles and lowering carbon footprints in manufacturing and disposal processes.

Future Prospects and Emerging Trends in Smart Polymers

Future prospects for self-healing polymers include advancements in autonomous damage repair and enhanced durability for applications in aerospace, electronics, and medical devices. Shape-memory polymers are evolving with improvements in multi-shape capability and faster response times, enabling innovative uses in soft robotics and minimally invasive surgery. Emerging trends in smart polymers emphasize stimuli-responsive behavior, integration with nanomaterials, and sustainable, eco-friendly designs for next-generation adaptive materials.

Stimuli-responsive materials

Self-healing polymers autonomously repair damage through chemical reactions triggered by stimuli such as heat or light, while shape-memory polymers undergo reversible shape changes in response to external stimuli like temperature variations, making both critical classes of stimuli-responsive materials for advanced smart applications.

Supramolecular chemistry

Supramolecular chemistry enables self-healing polymers to autonomously repair damage through reversible non-covalent interactions, whereas shape-memory polymers rely on programmed phase transitions to recover predefined shapes.

Dynamic covalent bonds

Dynamic covalent bonds in self-healing polymers enable reversible bond exchange for damage repair, whereas in shape-memory polymers, they facilitate reversible network restructuring to recover original shapes under stimuli.

Thermal actuation

Self-healing polymers restore functionality through chemical or physical repair mechanisms, while shape-memory polymers utilize thermal actuation to change and recover predefined shapes upon heating.

Intrinsic healing mechanisms

Self-healing polymers rely on intrinsic healing mechanisms such as reversible covalent bonds or dynamic supramolecular interactions to autonomously repair damage, whereas shape-memory polymers primarily recover original shapes through thermal or stimulus-responsive phase transitions without true molecular-level self-repair.

Reversible crosslinking

Reversible crosslinking in self-healing polymers enables dynamic bond reformation for damage repair, whereas in shape-memory polymers it facilitates molecular network rearrangement essential for programmed shape recovery.

Dual-functional polymers

Dual-functional polymers combine self-healing and shape-memory capabilities, enabling materials to autonomously repair damage while restoring pre-defined shapes, significantly enhancing durability and multifunctionality in advanced applications.

Strain recovery

Self-healing polymers autonomously repair damage to restore strain recovery over time, while shape-memory polymers recover strain rapidly through programmed thermal or mechanical triggers.

Microencapsulation

Self-healing polymers utilize microencapsulation to release healing agents upon damage, whereas shape-memory polymers rely on thermal or mechanical stimuli to recover their original form without embedded microcapsules.

Damage-sensing agents

Damage-sensing agents in self-healing polymers enable autonomous repair by detecting microcracks and triggering healing responses, whereas shape-memory polymers rely on external stimuli to recover predefined shapes without intrinsic damage detection capabilities.

Self-healing polymers vs Shape-memory polymers Infographic

njnir.com

njnir.com