Powder metallurgy offers precise control over material microstructure and composition, making it ideal for producing high-strength components with minimal waste. Additive manufacturing enables complex geometries and rapid prototyping by building parts layer by layer, which expands design freedom beyond traditional constraints. Both techniques optimize material utilization but differ significantly in manufacturing speed, cost, and part complexity capabilities.

Table of Comparison

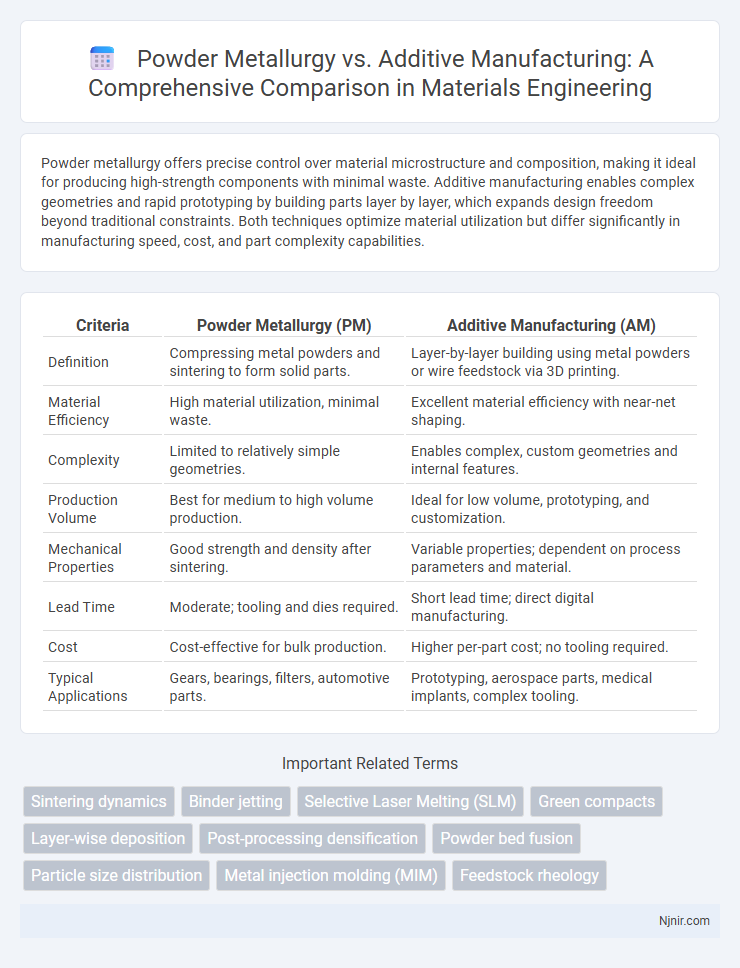

| Criteria | Powder Metallurgy (PM) | Additive Manufacturing (AM) |

|---|---|---|

| Definition | Compressing metal powders and sintering to form solid parts. | Layer-by-layer building using metal powders or wire feedstock via 3D printing. |

| Material Efficiency | High material utilization, minimal waste. | Excellent material efficiency with near-net shaping. |

| Complexity | Limited to relatively simple geometries. | Enables complex, custom geometries and internal features. |

| Production Volume | Best for medium to high volume production. | Ideal for low volume, prototyping, and customization. |

| Mechanical Properties | Good strength and density after sintering. | Variable properties; dependent on process parameters and material. |

| Lead Time | Moderate; tooling and dies required. | Short lead time; direct digital manufacturing. |

| Cost | Cost-effective for bulk production. | Higher per-part cost; no tooling required. |

| Typical Applications | Gears, bearings, filters, automotive parts. | Prototyping, aerospace parts, medical implants, complex tooling. |

Introduction to Powder Metallurgy and Additive Manufacturing

Powder metallurgy involves compacting and sintering metal powders to create precise, high-strength components with minimal material waste, widely used in automotive and aerospace industries. Additive manufacturing, also known as 3D printing, fabricates parts layer by layer directly from digital models, enabling complex geometries and rapid prototyping. Both techniques optimize material usage and are transforming modern manufacturing by enhancing design flexibility and production efficiency.

Historical Evolution of Processing Techniques

Powder metallurgy originated in the early 19th century, evolving from simple metal powder compaction and sintering techniques to advanced processes such as hot isostatic pressing and metal injection molding. Additive manufacturing emerged in the late 20th century, marked by the invention of selective laser sintering and fused deposition modeling, revolutionizing layer-by-layer material deposition from digital designs. Both technologies have progressively integrated computational tools and material science advancements, enhancing precision and enabling complex geometries in industrial applications.

Fundamental Principles and Process Flow

Powder metallurgy involves compacting metal powders into a desired shape followed by sintering to fuse particles together, emphasizing precise control of powder characteristics and thermal treatment for density and mechanical properties. Additive manufacturing builds components layer-by-layer from metal powders or wire using energy sources like lasers or electron beams, enabling complex geometries and customization without tooling. Both processes rely on powder quality and thermal history but differ significantly in manufacturing approach: powder metallurgy is largely subtractive or formative, while additive manufacturing is inherently digital and incremental.

Material Selection and Compatibility

Powder metallurgy offers a broad range of alloy options, including high-strength steels, superalloys, and refractory metals, enabling precise control over microstructure and mechanical properties for demanding applications. Additive manufacturing excels in processing complex geometries with materials like titanium alloys, aluminum, and nickel-based superalloys, but faces challenges with material anisotropy and limited availability of certified powders for some metals. Material compatibility in powder metallurgy is enhanced by established sintering techniques, while additive manufacturing requires careful optimization of process parameters to mitigate issues such as residual stresses and porosity in multi-material or functionally graded components.

Microstructural Characteristics and Properties

Powder metallurgy produces components with uniform microstructures and fine grain sizes due to controlled sintering processes, resulting in high density and excellent mechanical properties such as wear resistance and fatigue strength. Additive manufacturing offers tailored microstructural features, including directional grain growth and unique porosity patterns, which can enhance properties like impact toughness and complex geometries. While powder metallurgy excels in consistent and reliable properties for mass production, additive manufacturing enables customization at the microstructural level for specialized applications with varying mechanical performance.

Design Flexibility and Geometric Complexity

Powder Metallurgy offers limited design flexibility due to constraints in tooling and compaction processes, making it suitable for simpler, high-volume parts with uniform geometry. Additive Manufacturing excels in producing highly complex geometries and intricate internal structures without tooling, enabling optimized lightweight designs and rapid prototyping. The ability to manufacture customized components with complex lattice structures and internal channels is a key advantage of Additive Manufacturing over Powder Metallurgy.

Mechanical Performance and Reliability

Powder Metallurgy (PM) offers superior mechanical performance and reliability due to its uniform microstructure and controlled porosity, resulting in consistent strength and fatigue resistance. Additive Manufacturing (AM) enables complex geometries but can exhibit variable mechanical properties and reliability issues due to layer-by-layer fabrication, potential defects, and anisotropy. Optimizing process parameters in AM improves mechanical consistency, yet PM remains preferred for high-performance applications demanding predictable and repeatable mechanical behavior.

Sustainability and Resource Efficiency

Powder metallurgy offers enhanced material utilization with minimal waste by precisely controlling powder particle size and shape, resulting in a high-efficiency process that reduces energy consumption compared to traditional manufacturing. Additive manufacturing excels in sustainability by enabling layer-by-layer construction, which minimizes raw material use and supports complex, weight-optimized designs that reduce overall resource demands. Both technologies contribute to sustainable production by lowering environmental impact through optimized material use, energy efficiency, and enabling recycling of metal powders.

Industrial Applications and Case Studies

Powder metallurgy excels in producing high-strength, wear-resistant components for automotive and aerospace industries, with case studies highlighting its efficiency in mass production of gears and engine parts. Additive manufacturing offers unparalleled design flexibility and rapid prototyping in sectors like medical implants and aerospace, enabling complex geometries and customization as demonstrated in custom prosthetic devices and lightweight aircraft components. Both technologies are pivotal in industrial applications, where powder metallurgy ensures cost-effective volume production and additive manufacturing drives innovation through design optimization and material efficiency.

Future Trends and Technological Advancements

Powder metallurgy and additive manufacturing are converging through innovations such as advanced metal powders with controlled particle size and enhanced alloy compositions, improving material performance and reliability. Emerging technologies like high-speed sintering, hybrid manufacturing processes, and AI-driven design optimization are accelerating production efficiency and expanding applications in aerospace, automotive, and biomedical industries. Future trends emphasize sustainability with recycled powders, reduced energy consumption, and integration of real-time monitoring systems to ensure quality and precision in complex part fabrication.

Sintering dynamics

Sintering dynamics in powder metallurgy involve gradual particle bonding through heat-induced diffusion, whereas additive manufacturing utilizes localized, layer-by-layer melting and rapid solidification to achieve complex geometries.

Binder jetting

Binder jetting in powder metallurgy enables faster, cost-effective production of complex metal parts compared to traditional additive manufacturing methods, enhancing material efficiency and design flexibility.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) in additive manufacturing offers superior design flexibility and material efficiency compared to traditional powder metallurgy by enabling complex geometries through layer-by-layer laser fusion of metal powders.

Green compacts

Green compacts in powder metallurgy are dense, presintered parts formed by pressing powdered metals, whereas in additive manufacturing, green compacts are created layer-by-layer using powder-bed fusion or binder jetting techniques before sintering.

Layer-wise deposition

Powder metallurgy involves compacting metal powders into solid forms through pressing and sintering, whereas additive manufacturing builds parts layer-wise by selectively melting or binding powder particles to create complex geometries with precise layer deposition control.

Post-processing densification

Post-processing densification in Powder Metallurgy typically involves sintering under controlled temperature and atmosphere to enhance material density, whereas Additive Manufacturing relies on techniques like Hot Isostatic Pressing (HIP) and thermal treatments to reduce porosity and improve mechanical properties.

Powder bed fusion

Powder bed fusion in additive manufacturing enables precise, complex metal part production by selectively melting powder layers, contrasting with traditional powder metallurgy's compaction and sintering methods.

Particle size distribution

Powder metallurgy typically requires a narrow particle size distribution of 15-45 microns for optimal compaction, whereas additive manufacturing benefits from a broader distribution ranging from 20-65 microns to enhance flowability and layer adhesion.

Metal injection molding (MIM)

Metal Injection Molding (MIM) combines powder metallurgy and plastic injection molding to manufacture complex metal parts with high precision, superior mechanical properties, and cost-efficiency compared to traditional additive manufacturing techniques.

Feedstock rheology

Feedstock rheology in powder metallurgy is characterized by the flow behavior and compaction properties of metal powders, whereas in additive manufacturing it involves the viscosity and flow characteristics of metal powders or feedstock materials critical for layer deposition and precision.

Powder Metallurgy vs Additive Manufacturing Infographic

njnir.com

njnir.com