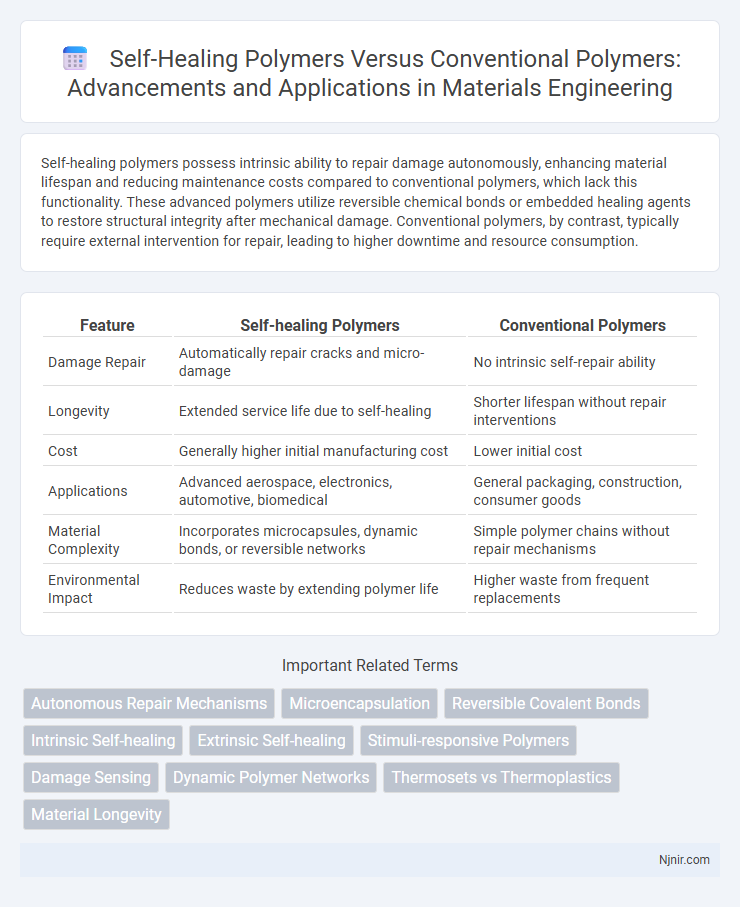

Self-healing polymers possess intrinsic ability to repair damage autonomously, enhancing material lifespan and reducing maintenance costs compared to conventional polymers, which lack this functionality. These advanced polymers utilize reversible chemical bonds or embedded healing agents to restore structural integrity after mechanical damage. Conventional polymers, by contrast, typically require external intervention for repair, leading to higher downtime and resource consumption.

Table of Comparison

| Feature | Self-healing Polymers | Conventional Polymers |

|---|---|---|

| Damage Repair | Automatically repair cracks and micro-damage | No intrinsic self-repair ability |

| Longevity | Extended service life due to self-healing | Shorter lifespan without repair interventions |

| Cost | Generally higher initial manufacturing cost | Lower initial cost |

| Applications | Advanced aerospace, electronics, automotive, biomedical | General packaging, construction, consumer goods |

| Material Complexity | Incorporates microcapsules, dynamic bonds, or reversible networks | Simple polymer chains without repair mechanisms |

| Environmental Impact | Reduces waste by extending polymer life | Higher waste from frequent replacements |

Introduction to Polymer Materials

Self-healing polymers are advanced materials designed to autonomously repair damage, enhancing durability and extending lifespan compared to conventional polymers that lack such regenerative capabilities. These innovative polymers incorporate dynamic covalent bonds or microcapsules containing healing agents, enabling restoration without manual intervention. In contrast, conventional polymers rely on physical strength and chemical stability but are prone to irreversible damage under stress or environmental factors.

Fundamentals of Self-Healing Polymers

Self-healing polymers are designed to automatically repair damage through intrinsic or extrinsic mechanisms, leveraging reversible chemical bonds or embedded healing agents. These materials contrast with conventional polymers, which lack the ability to restore their structural integrity once compromised. Advances in dynamic covalent chemistry and supramolecular interactions underpin the fundamental self-healing capabilities, enhancing durability and lifespan in various applications.

Structural Characteristics of Conventional Polymers

Conventional polymers possess fixed molecular architectures characterized by linear, branched, or cross-linked chains that lack reversible bonding, which limits their ability to autonomously repair damage. Their structural rigidity and permanent covalent bonds contribute to mechanical durability but result in irreversible failure upon crack formation or fatigue. The absence of dynamic covalent or supramolecular interactions restricts self-healing capabilities, necessitating external intervention for maintenance or repair.

Mechanisms of Self-Healing in Polymers

Self-healing polymers utilize dynamic covalent bonds, supramolecular interactions, or microencapsulated healing agents that activate upon damage to restore structural integrity, unlike conventional polymers that lack intrinsic repair capabilities. Mechanisms such as reversible Diels-Alder reactions, hydrogen bonding, and disulfide exchange enable autonomous or stimulated healing by re-forming broken molecular connections. These processes significantly extend polymer lifespan and enhance durability in applications ranging from coatings to aerospace materials.

Comparative Mechanical Properties

Self-healing polymers exhibit enhanced durability and fatigue resistance compared to conventional polymers, enabling recovery from microcracks and extending material lifespan. Their ability to autonomously repair structural damage reduces the need for frequent maintenance, unlike conventional polymers that accumulate irreversible mechanical degradation. Mechanical properties such as tensile strength and elasticity in self-healing polymers often surpass those of traditional polymers due to dynamic covalent bonds or reversible interactions incorporated in their molecular structure.

Durability and Lifespan Analysis

Self-healing polymers exhibit enhanced durability compared to conventional polymers due to their intrinsic ability to autonomously repair micro-cracks and damages, significantly extending their operational lifespan. Conventional polymers, lacking self-repair mechanisms, are prone to progressive degradation under mechanical stress, leading to premature failure and reduced service life. Studies indicate that self-healing polymers can increase material lifespan by up to 50%, providing cost-efficiency and sustainability in applications such as coatings, automotive parts, and electronics.

Environmental Impact and Sustainability

Self-healing polymers significantly reduce environmental impact by extending product lifespan and minimizing waste through autonomous repair mechanisms, unlike conventional polymers that often contribute to landfill accumulation due to permanent damage. These advanced materials enhance sustainability by enabling repeated use and decreasing the need for raw material extraction and energy-intensive manufacturing processes associated with polymer replacement. As a result, self-healing polymers align with circular economy principles, fostering resource efficiency and lowering carbon footprints compared to traditional polymer counterparts.

Industrial Applications: Self-Healing vs Conventional Polymers

Self-healing polymers revolutionize industrial applications by autonomously repairing microcracks, significantly extending the lifespan of materials in sectors such as aerospace, automotive, and electronics, unlike conventional polymers that require manual maintenance or replacement. These advanced polymers reduce downtime and maintenance costs by enhancing durability and reliability under mechanical stress and environmental exposure. Industrial usage of self-healing polymers leads to sustainable production processes and improved safety compared to the frequent failure and waste generation associated with traditional polymer materials.

Cost-Benefit Analysis

Self-healing polymers reduce long-term maintenance and replacement costs by autonomously repairing damage, which extends product lifespan and enhances durability compared to conventional polymers. Initial production costs for self-healing polymers are typically higher due to advanced materials and technology, but return on investment occurs through decreased downtime and waste. The cost-benefit analysis favors self-healing polymers in industries demanding reliability and sustainability, such as aerospace and automotive sectors.

Future Trends in Polymer Engineering

Self-healing polymers represent a transformative advancement in polymer engineering by autonomously repairing damage, significantly extending material lifespan compared to conventional polymers prone to irreversible wear and tear. Emerging trends emphasize integrating nanotechnology and multifunctional materials to enhance self-healing efficiency, mechanical strength, and environmental resistance. Future developments are likely to prioritize sustainability through bio-based self-healing polymers and advanced stimuli-responsive mechanisms for applications in aerospace, electronics, and biomedical devices.

Autonomous Repair Mechanisms

Self-healing polymers utilize embedded microcapsules or dynamic covalent bonds for autonomous repair, significantly extending material lifespan compared to conventional polymers that lack intrinsic healing capabilities.

Microencapsulation

Microencapsulation in self-healing polymers enables autonomous repair by releasing healing agents upon damage, vastly enhancing durability compared to conventional polymers lacking this capability.

Reversible Covalent Bonds

Self-healing polymers utilize reversible covalent bonds such as Diels-Alder adducts to autonomously repair damage, enhancing durability compared to conventional polymers with irreversible covalent bonds.

Intrinsic Self-healing

Intrinsic self-healing polymers regenerate molecular bonds autonomously through reversible covalent or supramolecular interactions, offering superior durability and repair efficiency compared to conventional polymers with no inherent self-healing capabilities.

Extrinsic Self-healing

Extrinsic self-healing polymers incorporate microcapsules or vascular networks containing healing agents that activate upon damage, offering enhanced durability and automatic repair compared to conventional polymers lacking such regenerative features.

Stimuli-responsive Polymers

Stimuli-responsive self-healing polymers autonomously repair damage through environmental triggers, offering enhanced durability and longevity compared to conventional polymers lacking intrinsic healing capabilities.

Damage Sensing

Self-healing polymers feature embedded damage sensing mechanisms that enable autonomous detection and repair of micro-cracks, significantly enhancing durability compared to conventional polymers lacking such responsive capabilities.

Dynamic Polymer Networks

Dynamic polymer networks in self-healing polymers enable reversible bond formation and efficient damage repair, offering superior durability and longevity compared to the static covalent bonds in conventional polymers.

Thermosets vs Thermoplastics

Self-healing thermoset polymers exhibit enhanced durability and crack repair capabilities compared to conventional thermoplastics, which typically lack intrinsic self-repair mechanisms and rely on physical melt flow for processing.

Material Longevity

Self-healing polymers significantly extend material longevity by autonomously repairing damage, unlike conventional polymers that degrade irreversibly over time.

Self-healing Polymers vs Conventional Polymers Infographic

njnir.com

njnir.com