Surface modification techniques enhance material properties by altering only the outermost layer, improving characteristics such as corrosion resistance, wear resistance, and biocompatibility without affecting the core material. Bulk modification involves changing the internal structure or composition throughout the entire volume of the material, leading to improved mechanical strength, toughness, and thermal stability. Selecting between surface and bulk modification depends on the application requirements, cost considerations, and desired balance between surface-specific functionalities and overall material performance.

Table of Comparison

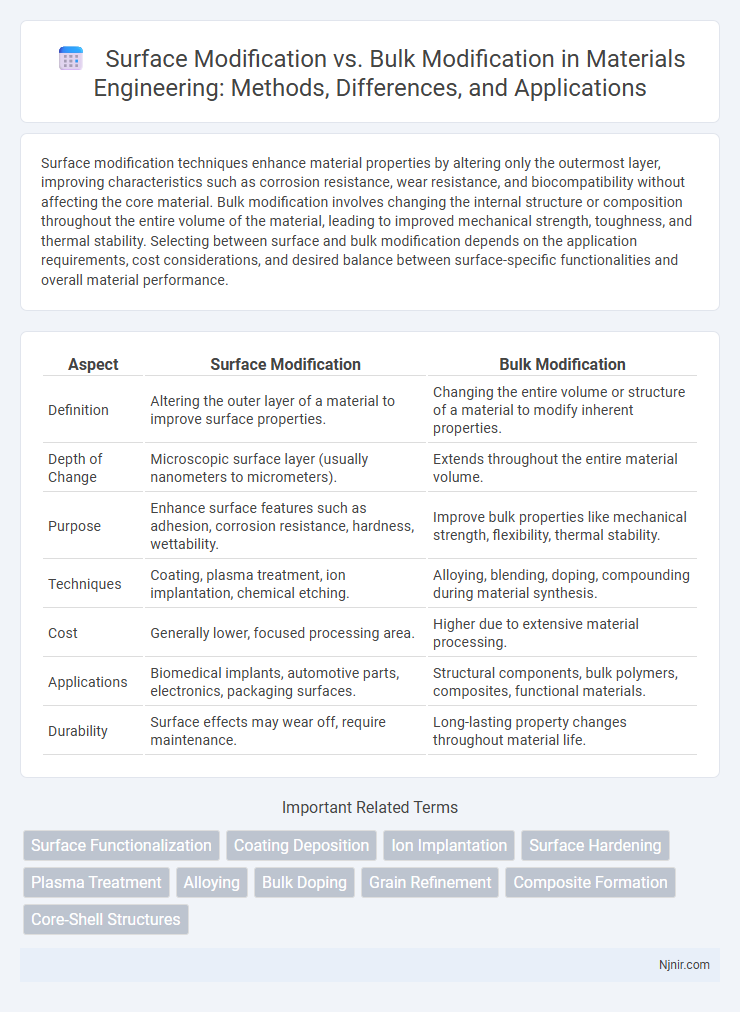

| Aspect | Surface Modification | Bulk Modification |

|---|---|---|

| Definition | Altering the outer layer of a material to improve surface properties. | Changing the entire volume or structure of a material to modify inherent properties. |

| Depth of Change | Microscopic surface layer (usually nanometers to micrometers). | Extends throughout the entire material volume. |

| Purpose | Enhance surface features such as adhesion, corrosion resistance, hardness, wettability. | Improve bulk properties like mechanical strength, flexibility, thermal stability. |

| Techniques | Coating, plasma treatment, ion implantation, chemical etching. | Alloying, blending, doping, compounding during material synthesis. |

| Cost | Generally lower, focused processing area. | Higher due to extensive material processing. |

| Applications | Biomedical implants, automotive parts, electronics, packaging surfaces. | Structural components, bulk polymers, composites, functional materials. |

| Durability | Surface effects may wear off, require maintenance. | Long-lasting property changes throughout material life. |

Introduction to Surface and Bulk Modifications

Surface modification enhances material properties by altering the outermost layer, improving attributes like corrosion resistance, adhesion, and wear without changing the core structure. Bulk modification involves changing the entire volume of a material through processes such as alloying or polymer blending, resulting in altered mechanical, thermal, and chemical characteristics throughout. These approaches serve distinct purposes: surface modification targets specific surface interactions while bulk modification fundamentally changes material behavior at a structural level.

Fundamental Differences Between Surface and Bulk Modification

Surface modification targets only the outermost layers of a material, altering properties such as corrosion resistance, wettability, or biocompatibility without affecting the core structure. In contrast, bulk modification changes the entire volume, impacting mechanical strength, thermal stability, and overall material performance. The fundamental difference lies in depth and scale: surface modification involves localized treatment at the micro- to nanometer scale, whereas bulk modification influences macroscopic properties through compositional or structural changes throughout the material.

Key Techniques in Surface Modification

Surface modification techniques primarily include plasma treatment, chemical vapor deposition (CVD), and ion implantation, which alter only the top few nanometers to micrometers of a material, enhancing properties like corrosion resistance, adhesion, and wettability without affecting the bulk characteristics. Techniques such as laser surface structuring and sol-gel coatings enable precise control over surface morphology and chemical functionality, providing tailored surface performance for biomedical implants, automotive components, and electronic devices. These methods contrast with bulk modification, which involves altering the material's internal structure through processes like alloying or thermal treatment, affecting the entire volume rather than merely the surface.

Methods of Bulk Modification

Bulk modification involves altering the properties of an entire material, typically using methods such as copolymerization, chemical grafting, and blending with additives or nanoparticles to enhance mechanical, thermal, or chemical characteristics. Other techniques include ion implantation and radiation crosslinking, which penetrate deep into the material matrix, ensuring uniform changes throughout. These methods differ significantly from surface modification, which targets only the outermost layer, by fundamentally changing the internal structure and composition of the bulk material.

Material Properties Affected: Surface vs Bulk

Surface modification primarily alters the outermost layer of a material, enhancing properties such as corrosion resistance, wear resistance, and surface hardness without significantly changing the bulk mechanical strength or elasticity. Bulk modification affects the entire volume of the material, influencing intrinsic properties like tensile strength, ductility, thermal conductivity, and overall structural integrity. Choosing between surface and bulk modification depends on the desired application, where surface treatment optimizes external interactions while bulk modification tailors comprehensive material performance.

Applications of Surface Modification in Industry

Surface modification enhances material properties by altering only the outer layer without affecting the bulk structure, making it ideal for improving corrosion resistance, wear resistance, and biocompatibility in industries such as automotive, aerospace, and medical devices. Techniques like plasma treatment, chemical vapor deposition, and laser surface engineering enable tailored surface characteristics that extend component lifespan and performance. These modifications optimize adhesion, hardness, and frictional behavior, crucial for manufacturing coatings, implants, and electronic components.

Applications of Bulk Modification in Materials Engineering

Bulk modification involves altering the internal structure or composition of a material, enhancing properties throughout its volume rather than just the surface. Applications in materials engineering include improving mechanical strength, thermal stability, and electrical conductivity of polymers and composites used in aerospace, automotive, and electronics industries. This approach enables the development of advanced materials with tailored bulk properties for demanding environments and multifunctional performance.

Advantages and Limitations of Surface Modification

Surface modification enhances material properties such as corrosion resistance, biocompatibility, and wear resistance by altering only the outer layer, preserving the bulk material's mechanical strength and reducing costs. It allows precise control over surface characteristics without affecting the internal structure, making it ideal for applications requiring specific surface functionalities like coatings, plasma treatments, or chemical grafting. Limitations include potential surface layer degradation over time, limited depth of modification, and sometimes insufficient durability under harsh conditions compared to bulk modification techniques.

Pros and Cons of Bulk Modification

Bulk modification enhances material properties throughout the entire volume, leading to improved mechanical strength, thermal stability, and chemical resistance, making it suitable for demanding applications. However, it often requires complex processing techniques, increases production costs, and may alter the original characteristics of the material undesirably. Unlike surface modification, bulk modification lacks precise control over localized functionalization, potentially affecting the entire structure even when changes are needed only on the surface.

Choosing Between Surface and Bulk Modification: A Comparative Analysis

Choosing between surface modification and bulk modification depends primarily on the desired property changes and application requirements. Surface modification targets the outermost layer, enhancing attributes such as corrosion resistance, adhesion, or biocompatibility without altering the material's core properties, making it cost-effective and minimally invasive. Bulk modification alters the internal structure or composition, providing uniform property changes throughout the material, ideal for applications requiring enhanced mechanical strength, thermal stability, or electrical conductivity.

Surface Functionalization

Surface functionalization enhances material properties by selectively modifying the outermost layers, offering precise control over chemical reactivity and biocompatibility compared to bulk modification that alters the entire material structure.

Coating Deposition

Coating deposition in surface modification selectively enhances material properties by applying thin layers without altering the bulk structure, whereas bulk modification integrates changes throughout the entire material volume for uniform property adjustment.

Ion Implantation

Ion implantation enables precise surface modification by altering the material's top atomic layers without affecting bulk properties, contrasting with bulk modification techniques that change the entire material composition.

Surface Hardening

Surface hardening enhances wear resistance by altering only the outer layer of a material through processes like carburizing or nitriding, whereas bulk modification changes the entire material's properties, often affecting overall strength and toughness.

Plasma Treatment

Plasma treatment enhances surface modification by altering only the outermost layer of materials to improve properties like adhesion and wettability without affecting the bulk material's mechanical characteristics.

Alloying

Surface alloying enhances corrosion resistance and mechanical properties by modifying only the outer layer, while bulk alloying uniformly alters the entire material's microstructure and composition.

Bulk Doping

Bulk doping enhances the intrinsic electrical and optical properties of materials by uniformly incorporating dopants throughout the entire volume, in contrast to surface modification which alters only the outermost layers.

Grain Refinement

Grain refinement in surface modification enhances mechanical properties locally by altering the microstructure only at the material's surface, whereas bulk modification achieves grain refinement throughout the entire volume, leading to uniform properties but higher processing costs.

Composite Formation

Surface modification enhances composite formation by improving interfacial bonding between matrix and filler, whereas bulk modification alters the entire matrix properties to achieve uniform composite characteristics.

Core-Shell Structures

Core-shell structures enable precise surface modification by altering only the outer shell while preserving the bulk properties of the core material for enhanced functionality.

Surface modification vs Bulk modification Infographic

njnir.com

njnir.com