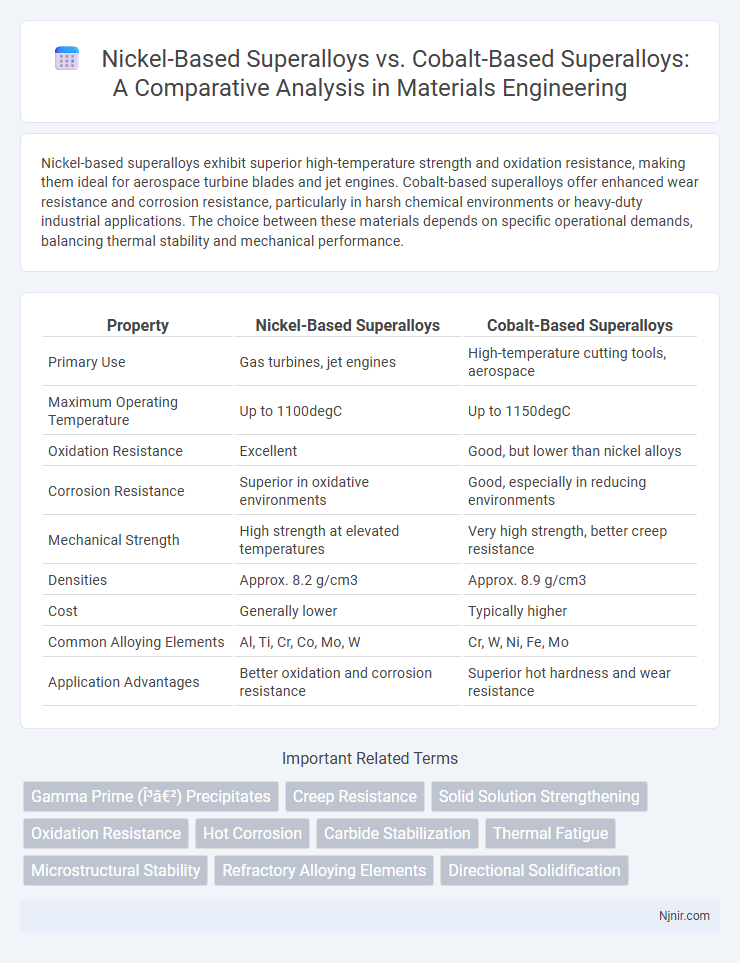

Nickel-based superalloys exhibit superior high-temperature strength and oxidation resistance, making them ideal for aerospace turbine blades and jet engines. Cobalt-based superalloys offer enhanced wear resistance and corrosion resistance, particularly in harsh chemical environments or heavy-duty industrial applications. The choice between these materials depends on specific operational demands, balancing thermal stability and mechanical performance.

Table of Comparison

| Property | Nickel-Based Superalloys | Cobalt-Based Superalloys |

|---|---|---|

| Primary Use | Gas turbines, jet engines | High-temperature cutting tools, aerospace |

| Maximum Operating Temperature | Up to 1100degC | Up to 1150degC |

| Oxidation Resistance | Excellent | Good, but lower than nickel alloys |

| Corrosion Resistance | Superior in oxidative environments | Good, especially in reducing environments |

| Mechanical Strength | High strength at elevated temperatures | Very high strength, better creep resistance |

| Densities | Approx. 8.2 g/cm3 | Approx. 8.9 g/cm3 |

| Cost | Generally lower | Typically higher |

| Common Alloying Elements | Al, Ti, Cr, Co, Mo, W | Cr, W, Ni, Fe, Mo |

| Application Advantages | Better oxidation and corrosion resistance | Superior hot hardness and wear resistance |

Introduction to Superalloys in Materials Engineering

Nickel-based superalloys exhibit exceptional high-temperature strength and corrosion resistance, making them ideal for aerospace turbine engines and power generation applications. Cobalt-based superalloys offer superior thermal stability and oxidation resistance but generally have lower creep resistance compared to nickel-based variants. Both superalloy types are engineered through precise alloying and microstructural control to optimize performance under extreme thermal and mechanical stress conditions in advanced materials engineering.

Chemical Composition: Nickel-based vs Cobalt-based Superalloys

Nickel-based superalloys primarily consist of nickel as the base element, combined with chromium, cobalt, aluminum, titanium, and molybdenum to enhance high-temperature strength and corrosion resistance. Cobalt-based superalloys feature cobalt as the main component, alloyed with chromium, nickel, iron, tungsten, and molybdenum, offering superior wear resistance and thermal stability. The chemical composition variations in these superalloys directly influence their mechanical properties, oxidation behavior, and performance in extreme environments such as aerospace and power generation applications.

Microstructural Differences and Phase Stability

Nickel-based superalloys exhibit a gamma prime (g') phase based on Ni3(Al, Ti) that provides superior creep resistance and phase stability at temperatures up to 1100degC, whereas cobalt-based superalloys rely on complex carbides and gamma prime phases with different compositions, showing better hot corrosion resistance and phase stability at extreme temperatures. The microstructure of nickel-based alloys typically includes g-g' two-phase regions enhancing high-temperature strength, while cobalt-based superalloys incorporate epsilon (e) and carbide phases that improve wear resistance but may sacrifice some long-term phase stability. Phase stability in nickel-based alloys is maintained through controlled alloying of Al, Ti, and other elements to restrict gamma prime coarsening, while cobalt-based alloys achieve stability via solid solution strengthening and stable carbide formation under severe thermal cycles.

Mechanical Properties and High-Temperature Strength

Nickel-based superalloys exhibit superior creep resistance and tensile strength at temperatures up to 1100degC, making them ideal for turbine blades and aerospace applications. Cobalt-based superalloys provide excellent wear resistance and maintain strength at slightly higher temperatures, around 1150degC, but generally have lower creep resistance compared to nickel-based counterparts. The enhanced high-temperature oxidation resistance of cobalt-based superalloys offers advantages in extreme environments, although nickel-based superalloys dominate due to their balanced mechanical properties and thermal stability.

Oxidation and Corrosion Resistance

Nickel-based superalloys exhibit superior oxidation resistance due to the formation of stable alumina (Al2O3) scales, which provide effective protection at high temperatures in oxidizing environments. Cobalt-based superalloys generally show enhanced corrosion resistance in sulfidizing and carburizing atmospheres, thanks to their Co-Cr matrix that forms protective chromia (Cr2O3) layers. While nickel-based alloys excel in high-temperature oxidation stability, cobalt-based alloys offer better resistance against aggressive chemical environments, making the choice dependent on specific application conditions.

Manufacturing Processes and Fabrication Techniques

Nickel-based superalloys are primarily manufactured using investment casting and powder metallurgy, benefiting from their excellent creep resistance and high-temperature stability, which allow precise control over grain structure during fabrication. Cobalt-based superalloys often require hot isostatic pressing and directional solidification due to their superior wear resistance and corrosion properties, demanding tailored thermal treatments to optimize mechanical performance. Both alloys necessitate advanced machining and surface coating techniques to enhance durability in high-stress environments such as aerospace and power generation.

Applications in Aerospace and Power Industries

Nickel-based superalloys dominate aerospace applications due to their exceptional high-temperature strength, oxidation resistance, and creep resistance, making them ideal for turbine blades, jet engines, and gas turbines. Cobalt-based superalloys offer superior hot corrosion resistance and moderate high-temperature strength, making them suitable for specific power generation components exposed to aggressive environments, such as gas turbine combustors and heat exchangers. The choice between these superalloys depends on the operating temperature, corrosion environment, and mechanical stress in aerospace and power industry components.

Cost Considerations and Material Availability

Nickel-based superalloys typically present higher raw material costs due to the extensive use of expensive elements like nickel, cobalt, and molybdenum, but benefit from widespread industrial availability and mature production techniques. Cobalt-based superalloys have higher material costs driven by cobalt's market volatility and geopolitical supply risks, yet they offer superior wear resistance and oxidation performance, making them essential for specific high-temperature applications. Material availability for nickel alloys is generally more stable globally, whereas cobalt supply is concentrated in a few regions, prompting concerns about long-term cost fluctuations and sourcing reliability.

Environmental Impact and Recyclability

Nickel-based superalloys exhibit higher recyclability due to their widespread industrial use and established recovery processes, which reduces environmental impact by minimizing raw material extraction. Cobalt-based superalloys, while offering superior high-temperature strength, present greater environmental challenges due to cobalt mining's ecological footprint and limited recycling infrastructure. Advances in recycling technologies for both materials aim to lower carbon emissions and resource depletion associated with superalloy production.

Future Trends and Emerging Research Directions

Research in nickel-based superalloys focuses on enhancing high-temperature creep resistance and oxidation stability through novel alloying elements and advanced processing techniques like additive manufacturing. Cobalt-based superalloys gain traction due to their superior thermal fatigue and corrosion resistance, prompting investigations into microstructural optimization and phase stability under extreme conditions. Future trends emphasize the development of hybrid alloys and high-entropy superalloys aiming to combine the strengths of nickel and cobalt systems for next-generation aerospace and power generation applications.

Gamma Prime (γ′) Precipitates

Nickel-based superalloys feature gamma prime (g') precipitates primarily composed of Ni3(Al, Ti) that enhance high-temperature strength and creep resistance, whereas cobalt-based superalloys rely less on g' precipitates, exhibiting different precipitate types such as carbides and gamma phase for thermal stability and mechanical performance.

Creep Resistance

Nickel-based superalloys exhibit superior creep resistance at high temperatures compared to cobalt-based superalloys due to their stable gamma-prime phase and optimized microstructure.

Solid Solution Strengthening

Nickel-based superalloys achieve superior solid solution strengthening through higher concentrations of alloying elements like chromium and molybdenum compared to cobalt-based superalloys, resulting in enhanced high-temperature strength and creep resistance.

Oxidation Resistance

Nickel-based superalloys exhibit superior oxidation resistance compared to cobalt-based superalloys due to the formation of stable and protective alumina (Al2O3) and chromia (Cr2O3) oxide layers at high temperatures.

Hot Corrosion

Nickel-based superalloys exhibit superior resistance to hot corrosion compared to cobalt-based superalloys due to their higher chromium content and stable oxide scale formation.

Carbide Stabilization

Nickel-based superalloys exhibit superior carbide stabilization due to their higher chromium and tantalum content compared to cobalt-based superalloys, enhancing grain boundary strength and creep resistance at elevated temperatures.

Thermal Fatigue

Nickel-based superalloys exhibit superior thermal fatigue resistance compared to cobalt-based superalloys due to their enhanced microstructural stability and higher creep strength at elevated temperatures.

Microstructural Stability

Nickel-based superalloys exhibit superior microstructural stability at high temperatures due to their gamma-prime (g') precipitates, while cobalt-based superalloys rely on gamma (g) phase with carbides for strength but generally show lower phase stability under prolonged thermal exposure.

Refractory Alloying Elements

Nickel-based superalloys contain higher concentrations of refractory elements like rhenium and tantalum for enhanced high-temperature strength, whereas cobalt-based superalloys typically use less refractory alloying elements, resulting in different thermal and mechanical performance profiles.

Directional Solidification

Nickel-based superalloys exhibit superior high-temperature strength and oxidation resistance in directional solidification compared to cobalt-based superalloys, making them the preferred choice for turbine blade manufacturing.

Nickel-based superalloys vs Cobalt-based superalloys Infographic

njnir.com

njnir.com