Elastomers are polymeric materials characterized by their high elasticity and ability to undergo significant deformation and return to their original shape, making them ideal for applications requiring flexibility and resilience. Thermoplastic elastomers (TPEs) combine the elastic properties of traditional elastomers with the processing advantages of thermoplastics, allowing them to be melted and reshaped multiple times without losing their rubber-like characteristics. The choice between elastomers and TPEs depends on factors such as mechanical performance, ease of manufacturing, and environmental resistance needed for specific engineering applications.

Table of Comparison

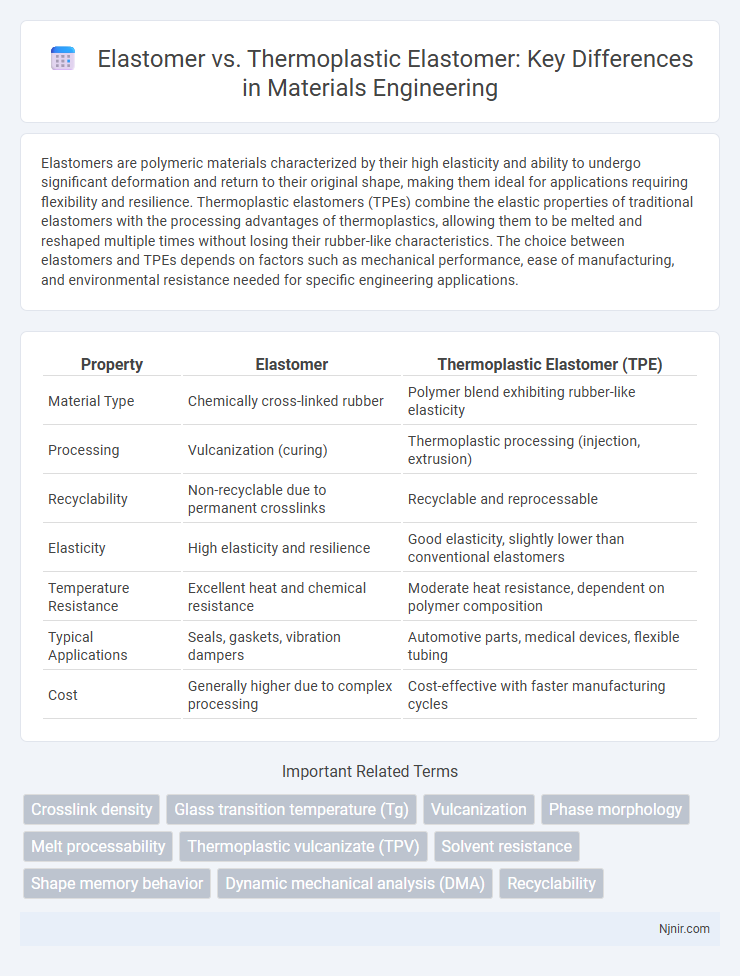

| Property | Elastomer | Thermoplastic Elastomer (TPE) |

|---|---|---|

| Material Type | Chemically cross-linked rubber | Polymer blend exhibiting rubber-like elasticity |

| Processing | Vulcanization (curing) | Thermoplastic processing (injection, extrusion) |

| Recyclability | Non-recyclable due to permanent crosslinks | Recyclable and reprocessable |

| Elasticity | High elasticity and resilience | Good elasticity, slightly lower than conventional elastomers |

| Temperature Resistance | Excellent heat and chemical resistance | Moderate heat resistance, dependent on polymer composition |

| Typical Applications | Seals, gaskets, vibration dampers | Automotive parts, medical devices, flexible tubing |

| Cost | Generally higher due to complex processing | Cost-effective with faster manufacturing cycles |

Introduction to Elastomers and Thermoplastic Elastomers

Elastomers, composed of cross-linked polymers, exhibit high elasticity and return to their original shape after deformation, making them ideal for applications requiring flexibility and durability. Thermoplastic elastomers (TPEs) combine the elastic properties of rubber with the processing advantages of thermoplastics, allowing them to be melted and reshaped multiple times without losing functionality. Key differences lie in TPEs' reversible physical bonds versus elastomers' permanent chemical cross-links, influencing recyclability and manufacturing processes in industries like automotive and consumer goods.

Chemical Structure and Composition

Elastomers consist of cross-linked polymer chains forming a three-dimensional network, giving them high elasticity and irreversible deformation resistance. Thermoplastic elastomers (TPEs) combine elastomeric properties with thermoplastic processing by blending or copolymerizing hard thermoplastic segments and soft elastomeric segments within linear or branched polymers, enabling reversible melting and reshaping. The chemical composition of elastomers typically involves covalent cross-links between polymer chains, while TPEs rely on physical cross-links such as microphase separation between incompatible blocks for elasticity.

Key Differences Between Elastomers and Thermoplastic Elastomers

Elastomers are polymers with highly elastic properties that return to their original shape after deformation, typically requiring vulcanization for cross-linking, resulting in permanent set and high thermal stability. Thermoplastic elastomers (TPEs) combine the elastic properties of elastomers with the processing advantages of thermoplastics, allowing them to be melted and reshaped without chemical curing, offering recyclability and ease of fabrication. Key differences include their processing methods, cross-linking requirements, and recyclability, with elastomers being chemically cross-linked and TPEs being physically cross-linked for reversible softening and hardening.

Mechanical and Physical Properties Comparison

Elastomers exhibit excellent elasticity with high tensile strength and exceptional elongation at break, making them ideal for applications requiring flexibility and resilience. Thermoplastic elastomers (TPEs) combine the elastic properties of elastomers with the processability of thermoplastics, offering easier molding and recycling while maintaining moderate mechanical strength and toughness. TPEs typically show lower heat resistance and slightly reduced mechanical durability compared to traditional elastomers but provide better chemical resistance and dimensional stability under varying conditions.

Processing and Manufacturing Methods

Elastomers are typically processed through vulcanization, a chemical curing method that enhances elasticity and strength by creating cross-links between polymer chains, often requiring heat and pressure. Thermoplastic elastomers (TPEs) can be processed using conventional thermoplastic methods such as injection molding, extrusion, and blow molding, allowing for easier recycling and faster manufacturing cycles without the need for vulcanization. The manufacturing flexibility of TPEs supports complex shapes and high-volume production, whereas elastomers are preferred for applications demanding superior elasticity and thermal resistance.

Applications in Industry

Elastomers are widely used in industries requiring flexible, durable materials such as automotive seals, gaskets, and vibration dampening components due to their excellent elasticity and resilience. Thermoplastic elastomers (TPEs) find extensive applications in manufacturing consumer goods, medical devices, and electrical connectors, benefiting from their easy processability, recyclability, and ability to be molded multiple times. The selection between elastomers and thermoplastic elastomers depends on specific industry needs for thermal stability, chemical resistance, and production efficiency.

Advantages and Limitations of Elastomers

Elastomers offer superior elasticity, excellent resistance to deformation, and exceptional flexibility across a wide temperature range, making them ideal for applications like seals, gaskets, and flexible components. Their limitations include lower processability compared to thermoplastic elastomers, difficulty in recycling, and sensitivity to certain chemicals and UV exposure which may degrade performance over time. Thermoplastic elastomers overcome processing and recyclability challenges but often have reduced heat resistance and mechanical strength compared to traditional elastomers.

Benefits and Drawbacks of Thermoplastic Elastomers

Thermoplastic elastomers (TPEs) combine the elasticity of elastomers with the processability of thermoplastics, enabling easier recycling and faster production cycles compared to traditional vulcanized elastomers. TPEs offer benefits such as design flexibility, excellent chemical resistance, and the ability to be molded and remolded multiple times without degradation. However, drawbacks include lower mechanical strength and heat resistance relative to some cured elastomers, limiting their use in high-temperature or heavy-load applications.

Sustainability and Recycling Considerations

Elastomers, typically cross-linked materials, present recycling challenges due to their permanent network structure, leading to limited reusability and energy-intensive disposal processes. Thermoplastic elastomers (TPEs) combine the elasticity of elastomers with thermoplastic processing advantages, enabling easier recycling through remelting and reprocessing without significant degradation. The sustainability profile of TPEs improves lifecycle management by reducing waste, lowering raw material consumption, and supporting circular economy principles.

Future Trends in Elastomer and Thermoplastic Elastomer Technologies

Future trends in elastomer and thermoplastic elastomer (TPE) technologies emphasize enhanced sustainability, with growing adoption of bio-based and recyclable materials to reduce environmental impact. Advances in blending techniques and nanocomposite formulations are improving mechanical properties and chemical resistance, enabling wider applications in automotive, healthcare, and consumer goods sectors. Integration of smart functionalities such as self-healing and shape-memory effects is driving innovation, positioning elastomers and TPEs as critical materials in next-generation flexible electronics and wearable devices.

Crosslink density

Elastomers exhibit higher crosslink density than thermoplastic elastomers, resulting in superior elasticity and permanent shape retention.

Glass transition temperature (Tg)

Thermoplastic elastomers generally exhibit a higher and more defined glass transition temperature (Tg) compared to traditional elastomers, enhancing their thermal stability and processing versatility.

Vulcanization

Vulcanization chemically crosslinks rubber molecules in elastomers to enhance durability and elasticity, while thermoplastic elastomers rely on physical blending of polymers and do not require vulcanization for their flexible properties.

Phase morphology

Elastomers exhibit a homogeneous phase morphology with amorphous polymer chains, whereas thermoplastic elastomers possess a distinct two-phase morphology combining hard thermoplastic domains dispersed within a soft elastomeric matrix.

Melt processability

Thermoplastic elastomers offer superior melt processability compared to traditional elastomers, enabling easier molding and recycling through melting and solidification cycles.

Thermoplastic vulcanizate (TPV)

Thermoplastic vulcanizates (TPVs) are a type of thermoplastic elastomer combining the elastic properties of vulcanized rubber with the processability of thermoplastics, offering superior flexibility, chemical resistance, and recyclability compared to conventional elastomers.

Solvent resistance

Thermoplastic elastomers exhibit superior solvent resistance compared to traditional elastomers due to their unique block copolymer structure and thermoplastic processing capabilities.

Shape memory behavior

Thermoplastic elastomers exhibit superior shape memory behavior compared to traditional elastomers due to their ability to reversibly transition between hard and soft phases through thermoplastic processes.

Dynamic mechanical analysis (DMA)

Dynamic mechanical analysis (DMA) reveals that thermoplastic elastomers exhibit higher storage modulus and improved temperature-dependent viscoelastic behavior compared to traditional elastomers, highlighting their enhanced mechanical performance and thermal stability for advanced applications.

Recyclability

Thermoplastic elastomers offer superior recyclability compared to traditional elastomers due to their ability to be remelted and reshaped without significant degradation.

elastomer vs thermoplastic elastomer Infographic

njnir.com

njnir.com