Green concrete reduces environmental impact by incorporating recycled materials and industrial byproducts, lowering carbon emissions compared to traditional Portland cement. Geopolymer concrete utilizes aluminosilicate-rich industrial waste like fly ash or slag to create a binder that cures through a chemical activation process without requiring high-temperature calcination. Both alternatives offer sustainable solutions in materials engineering, with geopolymer concrete generally providing superior durability and heat resistance over green concrete.

Table of Comparison

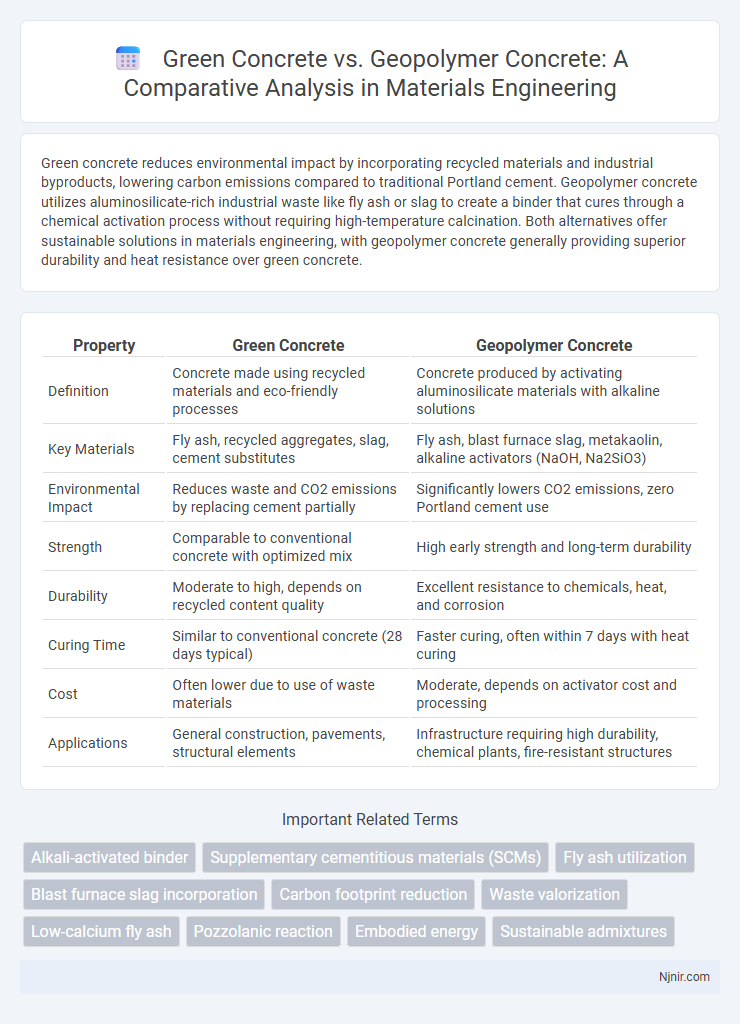

| Property | Green Concrete | Geopolymer Concrete |

|---|---|---|

| Definition | Concrete made using recycled materials and eco-friendly processes | Concrete produced by activating aluminosilicate materials with alkaline solutions |

| Key Materials | Fly ash, recycled aggregates, slag, cement substitutes | Fly ash, blast furnace slag, metakaolin, alkaline activators (NaOH, Na2SiO3) |

| Environmental Impact | Reduces waste and CO2 emissions by replacing cement partially | Significantly lowers CO2 emissions, zero Portland cement use |

| Strength | Comparable to conventional concrete with optimized mix | High early strength and long-term durability |

| Durability | Moderate to high, depends on recycled content quality | Excellent resistance to chemicals, heat, and corrosion |

| Curing Time | Similar to conventional concrete (28 days typical) | Faster curing, often within 7 days with heat curing |

| Cost | Often lower due to use of waste materials | Moderate, depends on activator cost and processing |

| Applications | General construction, pavements, structural elements | Infrastructure requiring high durability, chemical plants, fire-resistant structures |

Introduction to Sustainable Concrete Solutions

Green concrete utilizes industrial by-products like fly ash and slag to reduce cement content, lowering carbon emissions and environmental impact. Geopolymer concrete replaces traditional Portland cement with aluminosilicate materials activated by alkaline solutions, offering superior durability and resistance to chemical attack while minimizing greenhouse gas emissions. Both sustainable concrete solutions significantly contribute to reducing the carbon footprint of construction projects and promoting eco-friendly building practices.

Defining Green Concrete and Geopolymer Concrete

Green concrete is an eco-friendly building material made by incorporating recycled materials and industrial by-products like fly ash or slag, reducing carbon emissions compared to traditional Portland cement. Geopolymer concrete is a sustainable alternative utilizing aluminosilicate materials activated by alkaline solutions to form a binder, offering high durability and resistance to chemical attacks. Both types contribute to lowering environmental impact but differ in composition and the chemical processes involved in their formation.

Raw Materials and Composition Comparison

Green concrete primarily incorporates industrial by-products like fly ash, slag, and recycled aggregates to reduce cement content and lower carbon emissions. Geopolymer concrete uses aluminosilicate materials such as metakaolin, fly ash, or slag activated by alkaline solutions to form a polymeric binder, eliminating traditional Portland cement. The composition difference lies in green concrete partially replacing cement with waste materials, while geopolymer concrete relies on chemical activation of aluminosilicate precursors, resulting in distinct environmental and performance characteristics.

Environmental Impact Assessment

Green concrete significantly reduces carbon dioxide emissions by utilizing industrial by-products like fly ash and slag, promoting sustainable construction. Geopolymer concrete offers even lower environmental impact through minimal Portland cement use, thereby cutting greenhouse gas emissions by up to 80%. Life cycle assessments show geopolymer concrete has superior durability and reduced energy consumption compared to traditional green concrete, making it a promising solution for eco-friendly infrastructure.

Mechanical and Durability Performance

Green concrete, primarily made using recycled materials and supplementary cementitious substances, exhibits comparable compressive strength to conventional concrete but may show variability in tensile strength and modulus of elasticity depending on its composition. Geopolymer concrete, synthesized from industrial by-products like fly ash and slag with alkaline activators, demonstrates superior mechanical properties including higher compressive and flexural strength, enhanced resistance to chemical attacks, and better performance under high-temperature conditions. Durability assessments reveal that geopolymer concrete outperforms green concrete in terms of reduced permeability, improved sulfate and acid resistance, and lower carbon footprint, making it more suitable for sustainable infrastructure in aggressive environments.

Carbon Footprint Reduction Metrics

Green concrete reduces carbon footprint primarily by incorporating recycled materials and industrial byproducts like fly ash and slag, which lower cement usage and CO2 emissions. Geopolymer concrete achieves greater carbon footprint reduction by utilizing alkali-activated aluminosilicate binders, eliminating ordinary Portland cement and cutting emissions up to 80%. Lifecycle assessment metrics reveal geopolymer concrete often has a substantially lower embodied carbon per cubic meter compared to traditional green concrete formulations.

Production Processes and Energy Consumption

Green concrete production involves replacing traditional cement with industrial byproducts like fly ash or slag, significantly reducing CO2 emissions and energy consumption during manufacturing. Geopolymer concrete utilizes alkali-activated aluminosilicate materials, minimizing reliance on Portland cement and lowering energy use by curing at ambient or moderately elevated temperatures. Both methods decrease environmental impact compared to conventional concrete, but geopolymer concrete often achieves greater energy savings through reduced clinker production and enhanced waste material utilization.

Challenges in Large-Scale Implementation

Green concrete faces challenges in large-scale implementation due to the variability of industrial by-products like fly ash and slag, which affect consistency and durability. Geopolymer concrete's reliance on alkali activators and specific curing conditions limits its adoption in conventional construction settings. Both materials require further standardization and infrastructure adjustments to support widespread use and ensure reliable performance in diverse environments.

Case Studies and Real-World Applications

Case studies reveal that green concrete, incorporating industrial by-products like fly ash and slag, significantly reduces carbon emissions in construction projects such as the Singapore Sports Hub and the California High-Speed Rail. Geopolymer concrete demonstrates superior durability and chemical resistance in infrastructure exposed to harsh environments, exemplified by projects in Australia's mining industry and various coastal structures. Real-world applications highlight that green concrete is favored for sustainable urban developments, while geopolymer concrete excels in industrial and marine settings due to its enhanced mechanical properties and environmental benefits.

Future Prospects in Eco-Friendly Concrete Technology

Green concrete and geopolymer concrete represent significant advancements in eco-friendly construction materials with promising future prospects. Green concrete utilizes industrial by-products such as fly ash and slag to reduce CO2 emissions, while geopolymer concrete leverages aluminosilicate materials to eliminate the need for traditional Portland cement, drastically lowering carbon footprints. Innovations in geopolymer concrete formulations and large-scale adoption can revolutionize sustainable infrastructure by enhancing durability, reducing environmental impact, and supporting carbon neutrality goals in the construction industry.

Alkali-activated binder

Alkali-activated binder in geopolymer concrete offers superior environmental benefits and enhanced durability compared to traditional green concrete using Portland cement.

Supplementary cementitious materials (SCMs)

Green concrete and geopolymer concrete both utilize supplementary cementitious materials (SCMs) such as fly ash, slag, and silica fume to enhance durability and reduce environmental impact by minimizing Portland cement consumption.

Fly ash utilization

Geopolymer concrete utilizes fly ash as a primary binder to reduce carbon emissions and enhance durability compared to traditional green concrete, which often incorporates fly ash as a partial cement replacement.

Blast furnace slag incorporation

Incorporating blast furnace slag into geopolymer concrete significantly enhances its mechanical strength and durability compared to green concrete, while also reducing carbon emissions through the utilization of industrial byproducts.

Carbon footprint reduction

Geopolymer concrete reduces carbon footprint by up to 80% compared to traditional green concrete through the use of industrial by-products like fly ash and slag, minimizing Portland cement reliance.

Waste valorization

Geopolymer concrete achieves superior waste valorization by utilizing industrial byproducts like fly ash and slag as primary materials, significantly reducing environmental impact compared to traditional green concrete.

Low-calcium fly ash

Green concrete incorporating low-calcium fly ash enhances sustainability by reducing CO2 emissions, while geopolymer concrete with low-calcium fly ash offers superior mechanical strength and chemical resistance without using Portland cement.

Pozzolanic reaction

Green concrete utilizes natural pozzolanic materials to enhance cement hydration and strength, whereas geopolymer concrete relies on synthetic aluminosilicate polymers activated by alkaline solutions to achieve superior pozzolanic reactions and improved durability.

Embodied energy

Geopolymer concrete significantly reduces embodied energy by utilizing industrial by-products like fly ash and slag, whereas green concrete lowers embodied energy primarily through partial replacement of Portland cement with recycled materials.

Sustainable admixtures

Sustainable admixtures in green concrete primarily use industrial by-products like fly ash and slag, while geopolymer concrete leverages industrial waste-based aluminosilicate materials to significantly reduce carbon emissions and enhance durability.

green concrete vs geopolymer concrete Infographic

njnir.com

njnir.com